Catalog excerpts

Impulse cutting

Open the catalog to page 1

7G Impulser sets standards in separation of bars and tubes free from coolants and lubricants. Separation results because of the adiabatic principle, which means that due to a very short, reproducible impulse a very high energy is generated. , The impulse will be computed and controlled by a special software – depending on the material and separating surface. A special damping-unit in combination with an anvil transforms the residual energy. The loading of material is executed with 6m-, 9m- or 12m-materialloader (special system). Impulse cutting Sections up to approx. 300mm length are sorted...

Open the catalog to page 2

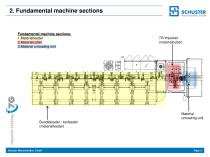

2. Fundamental machine sections Impulse cutting Fundamental machine sections: 1.Materialfeeder 2.Materialcutter 3.Material unloading-unit Material unloading-unit Bundleloader / barfeeder (materialfeeder) Schuster Maschinenbau GmbH

Open the catalog to page 3

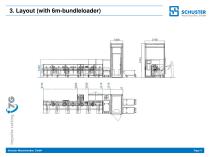

Impulse cutting Schuster Maschinenbau GmbH

Open the catalog to page 4

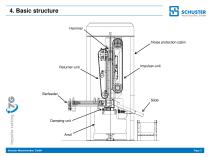

4. Basic structure Hammer Noise protection cabin Impulse cutting Schuster Maschinenbau GmbH

Open the catalog to page 5

5. Technical datas and configuration Technical datas (extraction): max. cutting energy Input power Weight (base machine) Cycle time ca. 1 x D (depending on the tolerances of material and geometry) Siemens (Simotion) Basic configuration: 7G Impulser with noise protection cabin Tool changing system Slide with sorting unit Impulse cutting Remote diagnostic system Advanced configuration: Schuster Maschinenbau GmbH Length and weight correction by diameter monitoring system Bundleloader up to a max. of 12m length Exchangeable tools Aligning-unit for hexagonal and octagonal profiles...

Open the catalog to page 6

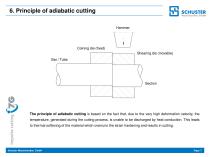

6. Principle of adiabatic cutting Hammer Coining die (fixed) Shearing die (movable) Bar / Tube Impulse cutting The principle of adiabatic cutting is based on the fact that, due to the very high deformation velocity, the temperature, generated during the cutting process, is unable to be discharged by heat conduction. This leads to thermal softening of the material which overruns the strain hardening and results in cutting. Schuster Maschinenbau GmbH

Open the catalog to page 7

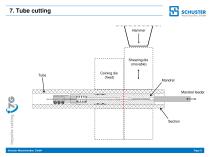

Shearing die (movable) Tube Impulse cutting Mandrel feeder Schuster Maschinenbau GmbH

Open the catalog to page 8

Tool in working position locking plate left Tool hydraulically extended locking plate right adjustment plate right Impulse cutting Schuster Maschinenbau GmbH adjustment plate left

Open the catalog to page 9

installation space (coining die) installation space (shearing die) Tool installation in reversed sequence. Chuck replacement Impulse cutting adapter with chuck adapter without chuck exchange chuck chuck replaced Manual height-adjustment of the feeder with crank handle (in accordance with diameter of bars or tubes) Schuster Maschinenbau GmbH

Open the catalog to page 10

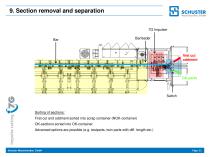

9. Section removal and separation 7G Impulser Bar Impulse cutting Sorting of sections: First cut and oddment sorted into scrap container (NOK-container) OK-sections sorted into OK-container Advanced options are possible (e.g. testparts, twin parts with diff. length etc.) Schuster Maschinenbau GmbH

Open the catalog to page 11

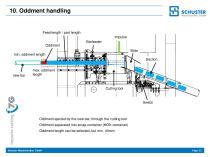

Feed length / part length Impulse Barfeeder Oddment Slide min. oddment length Section Cutting tool Impulse cutting Oddment ejected by the new bar, through the cutting tool Oddment separated into scrap-container (NOK-container) Oddment length can be selected, but min. 40mm Schuster Maschinenbau GmbH

Open the catalog to page 12

11. Sections (bars) - extraction Impulse cutting Schuster Maschinenbau GmbH

Open the catalog to page 13

12. Sections (tubes) - extraction Impulse cutting Schuster Maschinenbau GmbH

Open the catalog to page 14

13. Practical application (user cross section) cold work steel (e.g. 45SiCrV6) heat treatable steel (e.g. 25CrMoS4, 34CrNiMo6, 42CrMo4, C40, SAE1513Cr) bearing steel (e.g. 100Cr6) construction steel (e.g. E235, E355) case hardening steel (e.g. 16MnCrS5, 20MnCrS5, 20NiCrMoS2.2, ZF6) unalloyed quality steel (e.g. C8C) Tensile strength Bars: Tubes: Part length Bars: Tubes: up to 800mm (with special removal system) up to 214mm Bars: Tubes: approx. 3300 parts per hour approx. 2800 parts per hour Achievable mass tolerance ± 0,5 to 1% of part weight (bars) Impulse cutting Schuster Maschinenbau GmbH

Open the catalog to page 15

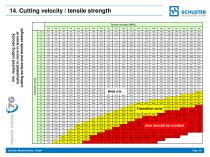

> O ® ■5 g S oh O ® ® o.E w ■£ w S S > -3 |T3 o E c T3 C ® P -- <D 3 ^ (0 O’® t P (0 3 ^ -5 w COO)

Open the catalog to page 16

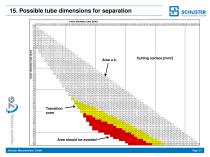

15. Possible tube dimensions for separation Impulse cutting Outer diameter tube [mm] Inner diameter tube [mm] Schuster Maschinenbau GmbH Transition zone Area should be avoided Page: 17

Open the catalog to page 17

16. Required customer informations Tensile strength of the material to separate Breaking strain of the material to separate Diameter or cutting surface Tolerance for diameter of the material to separate min. and max. section length Required tolerances for sections (length, concentricity, rectangularity of cutting surface etc.) Part spectrum Batch sizes and total quantity p.a. Special requirements (e.g. surface damages, surface finish etc.) Impulse cutting Conditions of the material to separate (adherences, oiling, straightness etc.) Schuster Maschinenbau GmbH Subsequent processing

Open the catalog to page 18