Catalog excerpts

White Paper schurter.com/downloads Projected Capacitive Input System (PCI) Multitouch Systems for Industrial Applications Multitouch technology is the focus of many new developments in the human machine interface (HMI) and medical fields. Based on projected capacitive technology, multitouch panels have undergone further development into an industry-compatible input system. The high electromagnetic compatibility (EMC) interference immunity requirements, adequate water tolerance and the glove operation option qualify it for industrial applications. SCHURTER Multitouch (source: SIEMENS) Projected-capacitive input systems with a sealed glass panel without dirt-collecting edges are easy to clean and are scratch-proof, abrasion- and chemical-resistant. They therefore allow multi-purpose use in industrial automation, machine construction and medical technology. The sensor positions are protected behind the glass panel and, for that reason, are not affected by mechanical stress. Multitouch allows more intuitive, faster and safer operation of machines, equipment and systems. New visualization and operating concepts have allowed a major leap in multitouch input system design innovation. Configuration and Function Projected-capacitive touch sensors consist of at least two electrically separate sensor surfaces, glass or polyester films that are coated with conductive, highly transparent indium tin oxide (ITO). Using an etching or laser process, the ITO surfaces are segmented into many small individual fields, mapped as x/y intersections into rows and columns. The design potentials of these sensor fields are wide-ranging and follow the different guidelines of the PCAP basic chip manufacturers. The structures are outside the viewing area with printed or laser-etched silver conductive ink circuitry contacted and conducting to the connector contacts. Film-based sensors are laminated so they are highly transparent and electrically insulating. As a result, a matrix network of individually addressable sensors with quiescent reference capacitances is generated over the entire active surface. With the approach of a finger its position is detected by the change in the capacitance of the individual sensor. Through the interpolation of the adjacent sensor capacitances the controller can calculate the exact positions of the activations and convert them into the corresponding x/y-coordinates. The matrix arrangement of the individual capacitive sensors requires no calibration. As a result, industry-compatible projected capacitive multitouch systems always work with position precision even under harsh environmental conditions. The electronic evaluation of the touch detection works using two principal methods. In both types a capacitive sensor field is projected through non-conductive media such as glass. The change in the self-capacitance or the mutual capacitance of the sensors is determined in the process. In the selfcapacitance method the increased charge flow of the x- and y-sensors due to the approach is determined at the ground level. The activation position is the point where the sensors display an increased charge flow. The mutual capacitance method detects a change in the sensor matrix capacitance due to a parallel coupling of the finger at the intersections. Both evaluation methods have advantages and disadvantages. The electronics of an industrycompatible PCI touch controller ideally uses a combination of both methods. Industrial requirement: interference immu nity, water tolerance and glove operation One of the most important factors for achieving industry-compatibility is immunity to EMC interferences with the system. During EMC radiation the touch panel must be operated with at least two actuators. That is the only way absolute EMC immunity can be qualified. Input Systems To achieve an EMC immune multitouch panel, two main sources of interference are considered. The first sources of interference behind the touch panel are integrated displays and switch mode power supplies. The EMC standard according to IEC- 61000-4-3 refers to these interferences. Furthermore, the IEC61000-4-6 EMC standard defines the gridlinked coupling of voltage peaks and frequencies. Elimination of interference signals so that the multitouch panel works with position precision without causing a deviation of the touch function and no false activations is the prerequisite for the achieving EMC class A conformity. This EMC immunity is achieved with optimized AD converters, integrated RC filters, enhanced drive voltages and complex algorithms, e.g., the frequency-hopping technique. In addition, an enhanced signal-to-noise ratio is obtained with a sensor design adapted perfectly to the electronics. This optimization of interference-immune sensor sensitivity allows finger activation through several layers of medical gloves and thicker leather construction gloves. Water must never lead to false activations of the multitouch panel. An additional requirement in the medical field particularly is resistance to saline solution. The possibility of achieving complete water resistance consists in the selection of optimal controllers and their measurement methodology. Thus PCI input systems are possible, even for use under running water with simultaneous detection of the finger activation. Absolute industry-compatibility however will only be achieved if all requirements, i.e., EMC interference immunity, water tolerance and glove operability can be guaranteed with a single software setting. In any event, conventional, standard design PCAP controllers and sensors from the consumer sector do not satisfy these high industry requirements.

Open the catalog to page 1

White Paper schurter.com/downloads www.schurter.com/downloads System integration: the multitouch screen becomes the multitouch panel At SCHURTER glass-based sensors up to 24” are liquid bonded to the front glasses with a fully automated process in the clean room. A specially designed system determines the glass thicknesses of the sensors and front glasses in the first step, then calculates the necessary amount of adhesive and bonds the glasses at a defined, fixed distance. Highly transparent UV adhesives that can also cure with air humidity are used exclusively. Reliable bonding can thus be...

Open the catalog to page 2All SCHURTER catalogs and technical brochures

-

FMAD NEO

6 Pages

-

SUSTAINABILITY REPORT 2022

37 Pages

-

THS

5 Pages

-

TTS

4 Pages

-

Product News

4 Pages

-

FMAB NEO

12 Pages

-

FPG1

4 Pages

-

FMAB HV

6 Pages

-

UMT-W

4 Pages

-

OGN

3 Pages

-

0712

3 Pages

-

CPS

7 Pages

-

DG12

10 Pages

-

4751

4 Pages

-

FMAD CP

4 Pages

-

4783

4 Pages

-

EF11

8 Pages

-

PFRY

4 Pages

-

PFRA

6 Pages

-

PFMF

4 Pages

-

PFDF

3 Pages

-

Company Profile

20 Pages

-

Voltage Selector

1 Pages

-

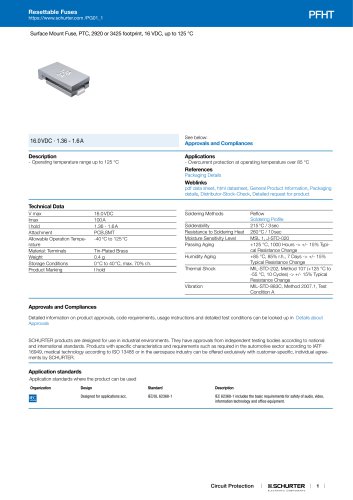

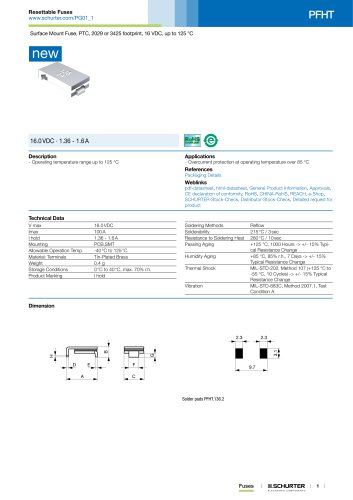

Resettable Fuses

1 Pages

-

6051.2067

3 Pages

-

6051.2068

3 Pages

-

Suppression Chokes DKIH-1

6 Pages

-

4797-5

4 Pages

-

6051.2063

3 Pages

-

6051.2061

3 Pages

-

6051.2015

3 Pages

-

3-108-993

2 Pages

-

3-100-361

3 Pages

-

GP21

3 Pages

-

AURORA Complete Solutions

2 Pages

-

FMER SOL

10 Pages

-

CMF2, CMF5

3 Pages

-

CDS1

5 Pages

-

DKIH-3

6 Pages

-

4710-5

5 Pages

-

Touchkit

3 Pages

-

USN 1206

3 Pages

-

FPBB RAIL

7 Pages

-

DD14

8 Pages

-

VAC19KS

3 Pages

-

UMK 250

4 Pages

-

TA35 Rocker 1Pole

6 Pages

-

4761

3 Pages

-

4732

4 Pages

-

FUS

3 Pages

-

DKIH

6 Pages

-

FSO

2 Pages

-

CSO

3 Pages

-

CMF1, CMF4

3 Pages

-

FMAC NEO

5 Pages

-

MSM DP 30

8 Pages

-

PSE AE 16

3 Pages

-

MSM LA CS 22

7 Pages

-

MSM LA CS 19

6 Pages

-

PSE AE 30

5 Pages

-

PSE EX 16

5 Pages

-

PSE EX 19

5 Pages

-

PSE NO 19

6 Pages

-

PSE NO 16

6 Pages

-

PSE EX 22

5 Pages

-

PSE NO 27

6 Pages

-

PSE NO 24

6 Pages

-

PSE NO 22

8 Pages

-

PSE IV 16

6 Pages

-

PSE HI 22

6 Pages

-

PSE NO 30

7 Pages

-

PSE M22 IV

7 Pages

-

MCS ES 18

3 Pages

-

MCS ES 22

3 Pages

-

6051.2094

3 Pages

-

6051.2093

3 Pages

-

6051.2078

3 Pages

-

6051.2077

3 Pages

-

6051.2070

3 Pages

-

6051.2072

3 Pages

-

6051.2071

3 Pages

-

6051.2037

2 Pages

-

6051.2030

3 Pages

-

6051.2032

3 Pages

-

6051.2031

3 Pages

-

6051.2027

3 Pages

-

3-107-570

2 Pages

-

3-107-569

2 Pages

-

VAC13KS

4 Pages

-

DD21

5 Pages

-

DD11

5 Pages

-

DF11

6 Pages

-

DG11

7 Pages

-

typ_6051.2016

3 Pages

-

typ_6051.2008

3 Pages

-

typ_6051.2009

3 Pages

-

typ_6051.2001

4 Pages

-

typ_6051.2007

3 Pages

-

typ_6051.2003

3 Pages

-

typ_6051.2004

3 Pages

-

typ_4762

3 Pages

-

typ_3-101-514

3 Pages

-

typ_3-101-501

3 Pages

-

typ_3-100-528

3 Pages

-

typ_3-100-734

3 Pages

-

typ_3-100-526

3 Pages

-

typ_3-100-523

3 Pages

-

typ_3-100-524

3 Pages

-

typ_3-100-527

3 Pages

-

typ_3-100-522

3 Pages

-

typ_3-100-356

3 Pages

-

typ_3-100-355

3 Pages

-

typ_3-100-354

3 Pages

-

Application Note Surge

2 Pages

-

White Paper IP Protection

2 Pages

-

SWA2

2 Pages

-

PB 1021

2 Pages

-

TM12-111

6 Pages

-

PTS

4 Pages

-

Piezo Keypads

4 Pages

-

PB 1011

2 Pages

-

FMAD CEE

3 Pages

-

White Paper Data Center

4 Pages

-

White Paper SPICE library

4 Pages

-

White Paper Cord retention

4 Pages

-

SCHURTER and ESA cooperation

2 Pages

-

Efficient EMC Solutions

8 Pages

Archived catalogs

-

2020 PFHT

3 Pages

-

Product News 2018

4 Pages

-

SCHURTER Company Profile

10 Pages

-

PFDF

3 Pages

-

2015 PFHT

3 Pages

-

PFUF

3 Pages

-

SCHURTER Renewable Energies

6 Pages

-

SCHURTER Product News 2015

4 Pages

-

DKFP

5 Pages

-

FMAD RAIL

3 Pages

-

FMAC RAIL

3 Pages

-

FMBD NEO

6 Pages

-

FMAC SINE DCL

4 Pages

-

FMAC SINE

4 Pages

-

FMAB RAIL

3 Pages

-

FMBB NEO

11 Pages

-

FMBB RAIL

3 Pages

-

5120

10 Pages

-

SMD-FTT

1 Pages

-

OMZ 125

1 Pages

-

4840.2200

2 Pages

-

6051.5003

2 Pages

-

6000.0224

2 Pages

-

6051.2030

2 Pages

-

6051.2003

2 Pages

-

FLBB

2 Pages

-

4741

2 Pages

-

P685

2 Pages

-

KE

4 Pages

-

GSF2

4 Pages

-

GSF1

5 Pages

-

Felcom 64

4 Pages

-

6135

5 Pages

-

KG-Bowdencable

4 Pages

-

KD-Bowdencable

4 Pages

-

DC21

3 Pages

-

1074

4 Pages

-

DC11

5 Pages

-

CMF3, CMF6

2 Pages

-

PFNF

3 Pages

-

ESO 10.3x38

1 Pages

-

SHT 6.3x32

1 Pages

-

Product Overview Switches

2 Pages

-

KEB2

1 Pages

-

New product: 6610

3 Pages

-

New product: UMZ 250

3 Pages

-

New product: CSO

2 Pages

-

New product: UST 1206

2 Pages

-

New product: UMF 250

3 Pages

-

New product: UMT-H

3 Pages

-

TA35 Rocker 2Pol

8 Pages

-

SCHURTER range at a glance

236 Pages

-

ASO / FSO

8 Pages

-

Flyer UMT 250 / UMZ 250

8 Pages

-

SCHURTER - Flyer MSM CS

2 Pages

-

Varistors

40 Pages

-

Flyer MGA-S

6 Pages