Catalog excerpts

Non Drip Cam-Slide® Fetterolf Line Blinding System

Open the catalog to page 1

Safe, Fast, and Convenient Blinding product lines connected to reactors, vessels or tanks is a business critical procedure in most chemical, petrochemical, tank storage, refinery or pharmaceutical plants. Positive Shut-Off No Spreading of Pipe Required Visible Position Indicator Fast acting line blinds ensure the safety of personnel engaged in maintenance and operations. They provide 100% positive isolation and when used in tandem with isolation valves provide the highest level of plant and personnel safety. Fast, One-Person Operation Minimum Maintenance Available in CS, SST, and most...

Open the catalog to page 2

Swinging Types Sliding Types Cam-Set® with Counterweight - 81FC-* High Temperature Cam-Slide® - 81HS Cam-Set® with Strainer - 81FC-* Cam-Slide® with Rupture Disc - 81CS-* Stacey® Line Spreading Blind - 81FS * to indicate model varia

Open the catalog to page 3

Fast, Safe, & Clean Line blinding is a proven method used to ensure 100% positive isolation and thereby enhances worker safety and efficiency. By definition, in the open or closed position there are no drips or spills possible. Requirement for a Non Drip Design During the changing of the position from open to closed or vice versa, there is a possibility that some medium remains in the line. This medium could drip to the ground as during this time the blind is open to the atmosphere. This can be minimized on other models such as the Cam-Set® by draining the body of the line blind (drain...

Open the catalog to page 4

Space Saving Non Drip Options Half Plate Non Drip Cam-Slide® Model 81NS-HP Full Plate Non Drip Cam-Slide® Model 81NS-FP The Half plate design ensures the same non drip functionality without having the need for a large drip pan below the line blind body. This is important in some blinding locations where space below the pipeline is not available. It is achieved by enclosing the sides and bottom of the blind. In this instance two plates are provided – a blind (closed) and a through plate (open). A slot container is also provided to hold the plate not in use. The full plate design is the same...

Open the catalog to page 5

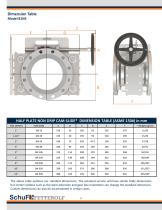

Dimension Table Model 81NS HALF PLATE NON DRIP CAM-SLIDE® DIMENSION TABLE (ASME 150#) in mm SIZE (ASME) The above table outlines our standard dimensions. The actuated version will have similar body dimensions but certain options such as the stem extension and gear box orientation can change the standard dimension. Custom dimensions can also be accomodated in certain cases.

Open the catalog to page 6

Operation of Non Drip Cam-Slide® Depressurize and drain line before use Indicator will be in unclamped position Turn hand wheel clockwise to actuate spectacle plate to blind position Turn hand wheel counterclockwise to unclamp spectacle plate Indicator will be in clamped position Turn hand wheel clockwise to re-clamp spectacle plate Operation of Half Plate Non Drip Cam-Slide® Depressurize and drain line before use 1 Turn hand wheel counterclockwise to unclamp spectacle plate. Indicator will be in unclamped position (below) Remove blind plate Insert thru plate 4 Turn hand wheel clockwise to...

Open the catalog to page 7

Half Plate Non Drip Cam-Slide® Cutaway* Position Indicator Hand Wheel Actuator Stem Spectacle Plate Plate Holder Seal Carrier Cams Non Spill Cover Body Stud/ Nuts *Same internal design is used in full plate and actuated versions Standard Material Chart Part Description Carbon Steel or Stainless Steel Spectacle Plate Stainless Steel Seal Carrier Stainless Steel Stainless Steel Actuation Stem Carbon Steel Body Studs Nuts Seals A194-2H or A194-8 FKM (Viton), FFKM, EPDM, Buna-N, NBR, PTFE etc Other materials and seal rings are available upon request Hand Wheel Extensions Locking Device Limit...

Open the catalog to page 8

Application Examples I. Refueling Vessel Installation - USA Non Drip Cam-Slide® designed for use onboard a refueling vessel that required zero spillage. Provided below with extended stem, customer specified hand wheel orientation, and drain and vent ports. II. Tank Farm Installation - Singapore 12” Non-Drip with extended hand wheel installed for ease of access from the walkway. Customer defined compact face to face dimensions

Open the catalog to page 9

Cam-Set Standard Pendulum Design Cam-Set Compact Cam-Set Fire Safe Cam-Set Filter Changer Cam-Set Sliding Blinds 81CS Series Cam-Slide Standard High Pressure Cam-Slide Fire Safe Cam-Slide Compact Cam-Slide Custom Designs High Temperature Cam-Slide Rupture Disc Changer Cam-Slide Orifice Plate Changer Cam-Set Enclosed 701 Blind (Maritime) Line Spreading 81FS Series SchuF Fetterolf Line Blind Portfolio Swinging Blinds 81FC Series Stacey Standard Stacey Inert Gas Blind Fetterolf Line Blind Customer List Chemical & Petrochemical Akzo Nobel BASF Bayer Braschem Celanese Chevron Phillips Dow...

Open the catalog to page 10

Contact information Cam-Set & Cam-Slide Valve Enquiry Form Contact name: Company: Country: E-mail address: Telephone number: Process details Medium: Operating Temperature: Operating Pressure: Other, please specify: Standard Cam-Set & Cam-Slide Models Description Please specify if models Please select which model you prefer ☐ Model A Carbon steel A to M do not meet ☐ Model B - Stainless ☐ Model C - Stainless ☐ Model M - Maritime your requirement steel wetted parts steel Body (triangle) Body pipe Seal carrier Spectacle plate Bolting Stem Seals Actuation Carbon steel Carbon steel Stainless...

Open the catalog to page 11

SchuF Valve Technology GmbH phone: +353 21 4837000 sales@schuf.ie Fetterolf Corporation phone: +1 610 584-1500 info@fetterolfvalves.com Your Sales Channel: SchuF Benelux B.V. phone +31 25 12 34 448 rklink@schuf.com SchuF-Armaturen und Apparatebau GmbH phone: +49 6198 571 100 sales@schuf.com Your Local Agent: La Tecnovalvo S.r.l. phone: +39 023503508 info@latecnovalvo.com SchuF South East Asia Pte. Ltd. phone +31 620 62 66 64 mmulder@schuf.com SchuF Valves China Ltd. phone +86 27 83 316 569 schufchina@schuf.com UNITED KINGDOM SchuF (USA) Inc. phone: +1 843 8813345 sales@schuf.us SchuF Middle...

Open the catalog to page 12All SchuF Group catalogs and technical brochures

-

Changeover Valve 60WN/69WN

6 Pages

-

SchuF Fetterolf Valve Portfolio

30 Pages

-

Valve Seat Options

4 Pages

-

Control Valves

10 Pages

-

Diverter Valves

12 Pages

-

Globe Valves

32 Pages

-

Lift Plug Valves

16 Pages

-

Line Blind Cam-Set

16 Pages

-

Line Blind Cam-Slide

18 Pages

-

Automatic Recirculation Valve

12 Pages

-

Valves for Polymer Industry

8 Pages

-

Valves for Delayed Coking

12 Pages

-

Spray Rinse & Steam Handling

8 Pages

-

High Pressure Shut-Off Valve

2 Pages

-

Cryogenic Globe Valve

4 Pages

-

Maniflow Selector Valve (MSV)

12 Pages

-

Ram Bottom Outlet Valve

8 Pages

-

Sampling Valve

12 Pages

-

Disc Bottom Outlet Valve

12 Pages

-

Angle Control Valves

4 Pages

Archived catalogs

-

Line Blind Valves

16 Pages

-

SwitchPlug Data Sheet

5 Pages

-

Drain and Sampling Valves

8 Pages

-

Sampling valves

7 Pages

-

Y-Globe Control Valve

4 Pages

-

Piston Drain Valve Brochure

8 Pages

-

Diverter Valve Overview Brochure

12 Pages

-

Disc Bottom Outlet Valve

12 Pages

-

Valves for Alumina Service

6 Pages

-

Delayed Coking - Lift Plug Valve

12 Pages

-

Engineered Control Valves

8 Pages