Catalog excerpts

Lift Plug Valves Metal-To-Metal Sealing Multi-Way Valves

Open the catalog to page 1

Table of Contents Page Overview Standard Lift Plug Valves IsoPlug Valves SwitchPlug Multi-Way Valves General Specifications Case Studies Lift Plug Valve and Ball Valve Comparison Table Customer Enquiry Sheet SchuF Product Portfolio Overview SchuF is fully registered, accredited and certified worldwide

Open the catalog to page 2

Lift Plug Valves Patented Innovation SchuF is a highly specialised group of companies, whose expertise is the design and manufacture of process valves for critical service applications. SchuF is the inventor of the Lift Plug Valve. The patent dates back to 1914. Since its invention, SchuF has continued to develop this type of valve, with many innovations. These include the addition of electric or hydraulic actuators, and new applications such as switching variants. SchuF also pioneered the inverted plug design, which can be serviced in-line; designed flushing systems; and several...

Open the catalog to page 3

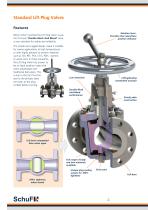

Standard Lift Plug Valves Features Rotation leverProvides clear open/close position indicator When SchuF invented the Lift Plug Valve it was the first ever ‘Double Block And Bleed’ valve, a new standard for safety and reliability. The simple and rugged design make it suitable for severe applications at high temperatures or with highly abrasive or erosive materials such as TDI, PET, PTA, CTG, PDH, styrene, or acetic acid. In those situations, the Lift Plug Valve has proven to be an ideal isolation valve with many advantages over traditional ball valves. This is due to the fact that the seal...

Open the catalog to page 4

Standard Lift Plug Valves Common Lift Plug Design Principles Additional Options ■ Dead-space free during flow ■ Optional flushing and/or purging (if required by the process) is still only required during operation from open to close or vice versa. This leads to significant cost savings in comparison with other valve designs (i.e. ball valve), which can require constant flushing ■ Integral ‘Double Block And Bleed’ design that ensures a perfect seal ■ Protected Valve Seat (PVS) – valve life will be increased as plug-to-body sealing faces are protected during media flow ■ High-temperature and...

Open the catalog to page 5

IsoPlug Valves Features The IsoPlug valve is a special-design lift plug valve that has been modified to meet the exacting requirements of processes which involve high temperatures and dirty media, such as Delayed Coking and Visbreaking. The IsoPlug valve features the unique 3-line CDS (Coking Defence System) package, which comprises of steam flushing, draining, and a retractable bottom lid that enables the valve to be cleaned in-line. The CDS package ensures that the valve can always be kept clean, and avoids coke build-up. Lifting actuatorelectric option shown here Coking Defence System...

Open the catalog to page 6

IsoPlug Valves Key Design Principles ■ See page 4 for Common Lift Plug Design Principles ■ Integral Strength – in addition to technical innovations such as the optional CDS package (see opposite), the demanding requirements of the processes for which IsoPlug valves are designed result in a number of approaches to ensure maximum durability and reliability. These include single-piece casting of the yoke and upper body-flange/lid, which eliminates weld fatigue potential. Similarly, the plug and plug stem are cast as a single component, with the actuator spindle connection to the plug stem being...

Open the catalog to page 7

SwitchPlug Multi-Way Valves Features The SchuF SwitchPlug valve is a switching valve with typically one inlet and three outlets. It is used to switch media flow from one outlet to another in a defined sequence, while isolating all other outlets. It is commonly used in the refining industry for delayed coking due to its leak-tight metal-to-metal sealing characteristics and suitability for high temperature operation. The SwitchPlug consists of only a few moving parts – body, plug and actuator – and is therefore highly reliable. There is no gap between the plug and the valve body, where the fluid...

Open the catalog to page 8

SwitchPlug Multi-Way Valves Key Design Principles ■ Benefits – the SwitchPlug is designed to outperform conventional valves (e.g. ball valves) in services where sediments or, for example, coke particles can collect and cause equipment failure. In fact, the Coking Defence System developed by SchuF features a combination of gap-free design, integrated drain valves and distributed and tangential flushing (see image below) to ensure optimal coke-free valve operation. Configuration Options ■ ‘Y’ or ‘T’ Design – SchuF can provide the SwitchPlug in either a ‘Y’ (120°) or ‘T’ (90°) configuration....

Open the catalog to page 9

SwitchPlug Multi-Way Valves Flexibility of Design The SchuF SwitchPlug principal of design offers great flexibility in matching new valves to very specific customer requirements. The plug can be upward- or downward-oriented, whichever allows easier maintenance access. Electric actuation can incorporate the SchuF Lift-Turn-Seal operation. All flush and purge connections can be oversized. Above: 4-way SwitchPlug Valve, ‘T’-configuration, with all-electric actuation and flushing valve (to left) Weight (approx) (kg) Manual/Electrical Rating Size

Open the catalog to page 10

General Specifications Standard Lift Plug Valves IsoPlug Valves SwitchPlug Valves Rating ASME Class 150# to 2500# High temperature version to 1200 °C Size Standard Materials Body Stainless Steel, Duplex, Hastelloy, Incoloy, Inconel Titanium, WCB, WC6, C12, C12A, C5, other on request Full-bore roval or round Options Flanges Fully flanged RF and RTJ, DIN, ASME or through bolt holes Full or partial jacketing Purge and Flushing connections Five connections as standard: less or more on request Port size: 3/4“ or 1“, larger on request Flow Direction Manual, electric, pneumatic or hydraulic Lift...

Open the catalog to page 11

Case Studies Catofin Dehydrogenation Delayed Coking A leading provider of plastics runs an Air Products Catofin Deydrogenation plant. Coking systems require simplicity and crevice-free design ■ A de-oiler stripper takes C4+ heavies from C3 gas (propane); the bottom stream heavies are sent to 2 re-boilers to further remove C3. ■ If the valve is open, or in a particular switching position, the plug and the body form a smooth continuous contour, free of gaps and crevices. ■ Initially our client equipped the lines to and from the stripper with double block and bleed gate valves and spectacle...

Open the catalog to page 12All SchuF Group catalogs and technical brochures

-

Changeover Valve 60WN/69WN

6 Pages

-

SchuF Fetterolf Valve Portfolio

30 Pages

-

Valve Seat Options

4 Pages

-

Control Valves

10 Pages

-

Diverter Valves

12 Pages

-

Globe Valves

32 Pages

-

Line Blind Cam-Set

16 Pages

-

Line Blind Cam-Slide (Non-Drip)

12 Pages

-

Line Blind Cam-Slide

18 Pages

-

Automatic Recirculation Valve

12 Pages

-

Valves for Polymer Industry

8 Pages

-

Valves for Delayed Coking

12 Pages

-

Spray Rinse & Steam Handling

8 Pages

-

High Pressure Shut-Off Valve

2 Pages

-

Cryogenic Globe Valve

4 Pages

-

Maniflow Selector Valve (MSV)

12 Pages

-

Ram Bottom Outlet Valve

8 Pages

-

Sampling Valve

12 Pages

-

Disc Bottom Outlet Valve

12 Pages

-

Angle Control Valves

4 Pages

Archived catalogs

-

Line Blind Valves

16 Pages

-

SwitchPlug Data Sheet

5 Pages

-

Drain and Sampling Valves

8 Pages

-

Sampling valves

7 Pages

-

Y-Globe Control Valve

4 Pages

-

Piston Drain Valve Brochure

8 Pages

-

Diverter Valve Overview Brochure

12 Pages

-

Disc Bottom Outlet Valve

12 Pages

-

Valves for Alumina Service

6 Pages

-

Delayed Coking - Lift Plug Valve

12 Pages

-

Engineered Control Valves

8 Pages