Catalog excerpts

BENCH-TOP DISPERSERS LMX | The new benchmark for bench-top mixing. For smaller scale production or pilot batches, the Schold LMX mixer offers a solid choice. This mixer is designed from the ground up with versatility in mind. Its design allows operators to easily process batches from one quart up to ten gallons in volume. At Schold, we were inspired to make the LMX mixer robust, simple and easy to clean. Using a direct-coupled mixer shaft design, power and torque is on demand. The adjustable, centralized control panel and display ensure the operator can quickly see the status of the mixer....

Open the catalog to page 2

POST-MOUNT DISPERSERS VHS - VARIABLE HIGH-SPEED | The VHS disperser is ideal for dispersing, grinding and letting down batches of products up to 50,000 centipoise. Multiple blade options are available, including shear and pumper style blades. VLS - VARIABLE LOW-SPEED | The VLS mixer is designed to blend and incorporate the entire range of product viscosities where grinding is not necessary. Additionally, various blade options are available for optimized mixing. CO-AXIAL | The Schold Co-Axial Disperser integrates both a high-shear and low-speed blade combination, with the low-speed agitator...

Open the catalog to page 3

TANK-MOUNT DISPERSERS When a removable process vessel is not required, post-mounted configurations can be designed as tank-mounted models. Instead of having a separate leg or post to secure the dispersing head, all of the components are mounted directly on top of the process tank or vessel. Tank-mounted equipment can save space in tight factories and offer simpler maintenance with fewer mechanical parts. Schold offers two styles of tank-mounted equipment: FLANGE-MOUNT | Flange-mounted tank dispersers are ideal for applications where pressure or vacuum is required to process a batch. The...

Open the catalog to page 4

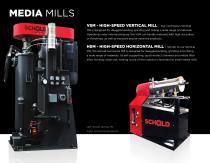

MEDIA MILLS VSM - HIGH-SPEED VERTICAL MILL | Our continuous Vertical Mill is designed for deagglomerating, grinding and milling a wide range of materials. Operating under internal pressure, the VSM can handle materials with high viscosities or thixotropy, as well as moisture and air-sensitive products. HSM - HIGH-SPEED HORIZONTAL MILL | Similar to our Vertical Mill, the Schold Horizontal Mill is designed for deagglomerating, grinding and milling a wide range of materials. Its self-supporting, quick-extract chamber and media filter allow for easy clean-out, making it one of the industry’s...

Open the catalog to page 5

FIXED-MOUNT | The Schold Fixed-Mount Press-Out is an extrusion discharge press with a large O-ring seal design. Hydraulic power pack horsepowers are available in ranges of three, five and ten, as floor-mounted or elevated vessel styles. Sizes range from lab scale to 10,000 lb. batches. With our Fixed-Mount Press-Out, Schold can help customize the function of your unit to provide constant flow-out of the vessel for your downstream critical processes. PORTABLE | The Schold Portable Press-Out is a self-contained, hydraulic press for discharging high viscosity, poor-flowing products. This...

Open the catalog to page 6

INLINE DISPERSERS ILD | Disperse, grind, mix, emulsify or homogenize with this versatile inline disperser. The Schold ILD processes one-pass or batch applications efficiently and quickly. With multiple configurations available, the ILD is an extremely versatile and highly customizable piece of equipment. Whether you’re processing chemicals, pigments, food products, pharmaceutical products, cosmetics, or more, the compact footprint of the ILD allows for simple integration for existing systems or as a brand new process. Available options include: different rotor/stator configurations for high...

Open the catalog to page 7

IMMERSION MILLS PRECISION CONTROL & AUTOMATION | Whether you prefer full manual control, fully automated control with recipes, or somewhere in between, Schold has the controls package for your operation. From push buttons to touch-screen HMI’s, we have what you need. CUSTOMIZATION | The Schold immersion mill can be outfitted with scraper arms, helical arms, or any other low speed blade to fit your needs. It can also be provided sans low speed blade in applications where vessel diameter versatility is required. EASE OF USE | Milling is an extremely vigorous process, and milling equipment...

Open the catalog to page 8

COMPLETE SYSTEMS | With extensive systems design and engineering experience, we are able to offer complete turn-key solutions, large or small. Whether your opportunity is a complete greenfield project, the addition of a production line, or simply a need to modify an existing process, rely on Schold as your single source supplier and partner. CONTROLS & AUTOMATION | Our individual equipment control packages typically include an operator station and separate motor control enclosure. Additional customization is available to integrate with your plant supervisory system. For complete facility...

Open the catalog to page 9

TANKS & VESSELS TANKS | Using our process and equipment expertise at Schold, we are able to design and engineer the perfect vessel for your application. Whether your process involves drawing vacuum on your product, heating and cooling of an in-process batch or press-out capability, we have the expertise to supply the vessel along with the core process equipment. We design to ASME/ANSI standards where required and stand behind the quality of every tank we supply. Additionally, we fit each vessel to our mixing equipment before shipment for quality assurance. RECONDITIONED EQUIPMENT | We...

Open the catalog to page 10All Schold Manufacturing catalogs and technical brochures

-

HORIZONTAL MEDIA MILL

2 Pages

-

LMX BENCH-TOP DISPERSER

2 Pages

-

ENGINEERED SYSTEMS

1 Pages

-

TANK-MOUNT DISPERSERS

2 Pages

-

ROTOR STATOR

2 Pages

-

CONTROLS & AUTOMATION

1 Pages

-

PRESS-OUTS

1 Pages

-

MEDIA MILLS

2 Pages

-

VIM VARIABLE IMMERSION MILL

2 Pages

-

HIGH-SPEED DISPERSERS

2 Pages

-

VACUUM DRUM MIXER

2 Pages