Catalog excerpts

Gear racks Standard and customized

Open the catalog to page 1

& FSC www.fsc.org MIX Paper from responsible sources FSC* C100493 Latest version of the catalogs You can always find the latest version of our catalogs in the Download area of our website. Disclaimer This publication has been compiled with great care and all information has been checked for accuracy. However, we can assume no liability for incorrect or incomplete information. We reserve the right to make changes to the information and technical data as a result of enhancements to our products. Reprinting or reproducing, even in part, is not permitted without our written consent.

Open the catalog to page 2

Page number 1.2 Properties of the gear racks/ conversion5 Standard gear rack8 2.1 Module pitches Q4 - Q11, helical toothed8 2.3 Q6 metric pitch, straight toothed22 2.4 Q6 stainless steel, helical toothed metric pitch23 2.5 Q6 stainless steel straight toothed module pitch24 2.6 Q6 stainless steel, straight toothed, metric pitch25 Customised gear racks26 2.7 Customised gear racks26 3.1 Gear rack fitting instructions / lubrication

Open the catalog to page 3

Gear racks Gear rack drives main feature is their high level of efficiency. They are the best choice for high axial forces. This drive rigidity is constant over the whole length. They are also very cost effective for long strokes of more than 2 m. With a rack and pinion system a slideway is driven by the pinion running on a a fixed gear rack. There is a basic difference between straight and helical toothed gear racks. Apart from typical dimensions, SCHNEEBERGER offers any cross sections with metric or module pitches. The max. one-piece length is 3000 mm. Joining with butt joints is possible...

Open the catalog to page 4

SCHNEEBERGER UNEAR TECHNCXOGY Properties of the gear racks/ conversion Modular tooth pitch (-M)

Open the catalog to page 5

SCHNEEBERGER UNEAR TECHNOLOGY Conversion/ hardness/ strength Converting a module m into a pitch p (straight toothed) and Transverse pitch ps for helical tooth racks

Open the catalog to page 6

SCHNEEBERGER UNEAR TECHNCXOGY Fields of application CUSTOMER-SPECIFIC BEARINGS AND GEAR RACKS On to new shores. SCHNEEBERGER involved in climate missions in Antarctica Wherever large ships and, in particular, their drive systems, are built, our linear technologies are making a decisive contribution. Large multifunctional long bed lathes can be used to turn, mill, grind or even repair huge crankshafts or drive shafts, over a stroke of 40 meters and with minimal tolerance. For these and similar applications, such as when manufacturing rotor heads or wind turbines for power engineering, we...

Open the catalog to page 7

Standard gear rack Q4 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNOLOGY Tooth rack: Pressure angle a = 20° ground, soft or hardened Outer surfaces: ground on all sides Quality: fp (mm) Fp (mm) Fp/1000 (mm) 4 in accordance with DIN 3962, 3963, 3967 Single pitch deviation Module < 3: 0.003 Module > 3: 0.0804 Total pitch deviation 0,015 for a 1000 mm Length 31 n Number of holes 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request

Open the catalog to page 8

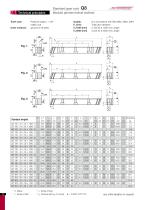

Standard gear rack Q5 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNCXOGY Tooth rack: Pressure angle a = 20° ground, soft or hardened Outer surfaces: ground on all sides Quality: 5 in accordance with DIN 3962, 3963, 3967 fp (mm) Single pitch deviation Fp (mm) Total pitch deviation 31 n Number of holes 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request

Open the catalog to page 9

Standard gear rack Q6 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNOLOGY Tooth rack: Pressure angle a = 20° ground, soft or hardened Outer surfaces: ground on all sides Quality: fp (mm) Fp (mm) Fp/1000 (mm) Fp/2000 (mm) 6 in accordance with DIN 3962, 3963, 3967 Single pitch deviation Module < 3: 0.006 Module > 3: 0.008 Total pitch deviation 0,035 for a 1000 mm Length 0,045 for a 2000 mm Length Standard lengths 31 n Number of holes 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request

Open the catalog to page 10

Standard gear rack Q7 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNCXOGY Tooth rack: Pressure angle a = 20° ground, soft or hardened Outer surfaces: ground on all sides Quality: fp (mm) Fp (mm) Fp/1000 (mm) Fp/2000 (mm) 5 in accordance with DIN 3962, 3963, 3967 Single pitch deviation Module < 3: 0,007 Module > 3: 0,009 Total pitch deviation 0.060 for a 1000 mm length 0.075 for a 2000 mm length Standard lengths 31 n Number of holes 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request Technical principles

Open the catalog to page 11

Standard gear rack Q8 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNOLOGY Tooth rack: Pressure angle a = 20° milled, soft Outer surfaces: ground on all sides 8 in accordance with DIN 3962, 3963, 3967 Total pitch deviation 0,150 for a 1000 mm Length 0,225 for a 2000 mm Length Standard lengths 31 n Number of holes 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request

Open the catalog to page 12

Standard gear rack Q9 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNCXOGY Tooth rack: Pressure angle a = 20° ground, nitrided Outer surfaces: ground on all sides Quality: 9 in accordance with DIN 3962, 3963, 3967 Fp (mm) Total pitch deviation 21 z Number of teeth 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request Technical principles

Open the catalog to page 13

Standard gear rack Q11 Module pitches helical toothed SCHNEEBERGER UNEAR TECHNOLOGY Tooth rack: Pressure angle a = 20° milled, induction hardened Outer surfaces: ground on all sides 11 in accordance with DIN 3962, 3963, 3967 Total pitch deviation 0,220 for a 1000 mm Length 0,330 for a 2000 mm Length 31 n Number of holes 41 ps Transverse pitch (ps=m*n/cos p) p = 19.5283° (19°31’42”) any other lengths on request

Open the catalog to page 14

Standard gear rack Q4 Module pitches straight toothed SCHNEEBERGER UNEAR TECHNCXOGY Tooth rack: Outer surfaces: Pressure angle a = 20° ground, soft or hardened ground on all sides Quality: fp (mm) Fp (mm) Fp/1000 (mm) 4 in accordance with DIN 3962, 3963, 3967 Single pitch deviation Module < 3: 0.003 Module > 3: 0.004 Total pitch deviation 0,015 for a 1000 mm Length n Number of holes p Pitch (p=m*n) any other lengths on request Technical principles

Open the catalog to page 15All SCHNEEBERGER AG Linear Technology catalogs and technical brochures

-

Schneeberger - Linear Bearings

138 Pages

-

Positioning systems / Slides

13 Pages

-

Positioning systems

8 Pages

-

Brochure générale

28 Pages

-

MINI-X

93 Pages

-

Slides - Dynamic and precise

34 Pages

-

Mineral casting

8 Pages

-

2-Stage Telescopic Actuators

4 Pages

-

AM Machine Components

25 Pages

-

Stage Telescopic Actuators

4 Pages

-

Company Profile

4 Pages