Website:

Schleich GmbH

Website:

Schleich GmbH

Catalog excerpts

Thermal-bonding machines, impregnation & resistive-heating systems Universal systems for coil production Expect more. Winding testers

Open the catalog to page 1

Thermal-bonding machines, as well as impregnation and trickle-impregnation systems serve for a safe bonding of all components within an electrical winding and to the lamination stack. This process is always based on heat, which is necessary for bonding self-bonding enameled magnet wire or to bond insulating resin to the winding. For heating, current is applied to the windings. This creates electrical losses in the winding resistances, which heats up the winding. We call this principle "resistive-heating method". An accurate measurement and regulation of the flowing current allows to control...

Open the catalog to page 2

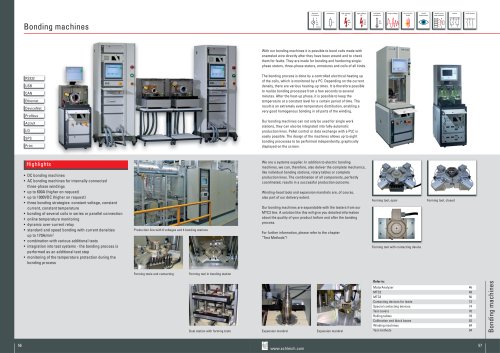

Thermal-bonding machines Controlled heating with current-generated heat With our thermal-bonding machines, coils produced with selfbonding magnet wire can be bonded directly after winding. If required, you can perform tests before and after the bonding process. The thermal-bonding machines are suited for coils of all types. Provided the contacting of the winding allows a current flow significantly higher in comparison to normal operation, a reliable bonding of single coils as well as 1- phase and 3-phase stators and armatures is possible. Manual thermal-bonding machines At manual...

Open the catalog to page 3

Impregnation systems Resistive-heating UV-dipping method SCHLEICH impregnation systems are used to bond stators with insulating resin by means of the resistive-heating UV-dipping method, which is suitable for winding systems of all kinds. It basically consists of the PC-controlled heating up followed by applying and curing the insulating resin. The impregnation process has four phases. While going through one phase after the other, the winding is continuously energized. The design of the impregnation systems allows to control several independent impregnation processes at the same time and...

Open the catalog to page 4

The universal SCHLEICH-concept treats a thermal-bonding or an impregnating process like an operational step within a chain of test steps. From an economic point of view, it doesn’t make sense to bond or impregnate a defective winding. This is why, before heating the winding with current, the winding is often tested. After the heating process, it may be appropriate to perform a final test. The screen layout during the tests and during the heating process is clearly structured; only key data and diagrams are indicated. Quality assurance is supported by numerous statistical analyses. A great...

Open the catalog to page 5

Heating windings with current-generated heat Method for increased starting temperatures The super fast, high-accuracy measurement technology delivers hundreds of thousands of current and voltage measurement values per second. With these values, the software continuously calculates, for example, the winding temperature. Based on the detected process values, the software controls the power module with varying heating methods. For heating, direct current or alternating current flows through the winding. The power dissipation created at the winding resistance is converted into heat. To achieve...

Open the catalog to page 6

Connection types & questionnaire Our thermal-bonding systems are available as single or multiple workstations. In addition, they are ideally suited to be integrated into fully-automatic production lines. Our impregnation systems are designed as single stations, rotaryswitching tables or conveyor systems. In order to meet your requirements, resistive-heating systems are available with varying configurations. In case you find no match for your specific application or if you have questions, please feel free to contact us any time. In addition to the products shown in this brochure, we will be...

Open the catalog to page 7

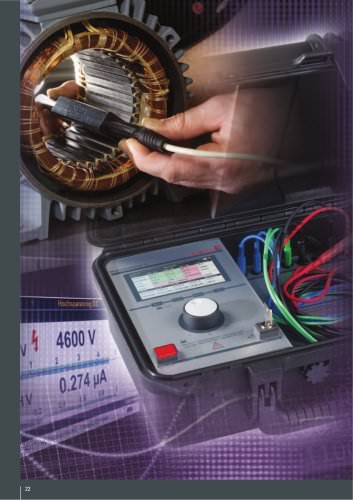

A deeper look into the winding Your gain – integration of efficient test methods Based on our test systems MTC3 or GLP3, the SCHLEICH-MODULARCONCEPT offers you many different options to add various winding and safety tests to your thermal-bonding or impregnation system. You can chose the test methods required for your testing task from a large pool of test options. This allows you to check windings for all types of faults. The combination of the test methods with our patented and awardwinning innovations guarantees the quality of your products. In every single device you will find will find...

Open the catalog to page 8

Contacting units, expanding mandrels, forming tools, … The mechanical adaptation of stators and their special contacting units is one of SCHLEICH’s key strengths. Heating system and mechanics are manufactured to match your task. For this purpose, we use manual or pneumatically controlled 4-wire clamps. It is important that they transfer the high currents and the measurement signals perfectly. The design is done at our own 3D-CAD work stations. With state-ofthe-art CNC machines, our mechanics department guarantees the production of high-quality components at low prices. Contacting units...

Open the catalog to page 9

Our software is based on the operating system Microsoft Windows®. The optimized user interface allows to carry out: • • • • • Heating with current Testing Generation of heating/test plans Printing of test protocols Statistical evaluation of the results By simply clicking the respective step with the mouse, you can edit the heating and test parameters. You don’t have to work with an extra heating-plan editor. Every operator can view the settings. Changes, however, can only be done by authorized personnel. All changes are stored in the history management and in the log. Heating | test process...

Open the catalog to page 10

Result protocol Details: resistance Details: surge voltage All results can be printed on the modern standard protocol either directly after the heating process or later. Before printing, you can select the language of the protocol. Standard languages: German, English, French, Dutch, Spanish, Italian and Russian. You can print the protocol in different ways as required: • Creating PDF-files If requested, the heating system creates a PDF-file that is either directly printed or stored on a USB flash drive, the internal hard disc or in a network directory. Editable field with your company logo...

Open the catalog to page 11All Schleich GmbH catalogs and technical brochures

-

MTC3

31 Pages

-

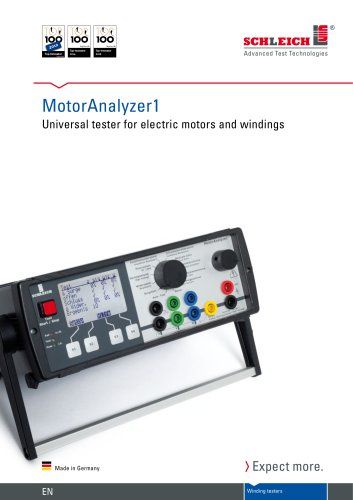

MotorAnalyzer1

8 Pages

-

GLP2-BASIC

15 Pages

-

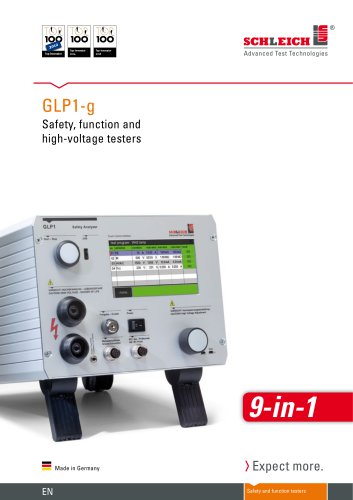

GLP1-g

19 Pages

-

MotorAnalyzer2

13 Pages

-

Winding Machines

1 Pages

-

MotorAnalyzer 1

8 Pages

Archived catalogs

-

Bonding Machines

1 Pages

-

GLP1-e - HIPOT TESTER

1 Pages

![MTC3 | Surgetester [Surge 6KV + R + HV + Rotation +++]](https://img.directindustry.com/pdf/repository_di/19475/mtc3-surgetester-surge-6kv-r-hv-rotation-176014_1mg.jpg)

![MTC2 | Surgetester - portable [3KV - 6KV - 12KV - 15KV - 24KV - 30KV]](https://img.directindustry.com/pdf/repository_di/19475/mtc2-surgetester-portable-3kv-6kv-12kv-15kv-24kv-30kv-176012_1mg.jpg)

![MotorAnalyzer | Universal motor analyzer [R + HV + Iso + Surge +++]](https://img.directindustry.com/pdf/repository_di/19475/motoranalyzer-universal-motor-analyzer-r-hv-iso-surge-176010_1mg.jpg)

![Handheld [PE + Iso + HV + Function]](https://img.directindustry.com/pdf/repository_di/19475/handheld-pe-iso-hv-function-176008_1mg.jpg)

![GLP3 | Combination tester [PE + Iso + Leakage + HV + Function + R + Visual +++]](https://img.directindustry.com/pdf/repository_di/19475/glp3-combination-tester-pe-iso-leakage-hv-function-r-visual-176006_1mg.jpg)

![GLP2-e/i | High voltage testers [up to 100KV AC / up to 40KV DC]](https://img.directindustry.com/pdf/repository_di/19475/glp2-e-i-high-voltage-testers-up-to-100kv-ac-up-to-40kv-dc-176004_1mg.jpg)

![GLP2-e/i | Single-/ Combination [PE + Iso + LC + HT + Function + R + Visual +++]](https://img.directindustry.com/pdf/repository_di/19475/glp2-e-i-single-combination-pe-iso-lc-ht-function-r-visual-176002_1mg.jpg)

![GLP1-e 60204 | EN 60 204 - VDE 0113 tester | [PE + Iso +HV]](https://img.directindustry.com/pdf/repository_di/19475/glp1-e-60204-en-60-204-vde-0113-tester-pe-iso-hv-175998_1mg.jpg)