Catalog excerpts

Welding systems for industrial and fencing mesh Systems MG950, MG900, MG700, MG600, Syrocut and POSIWELD

Open the catalog to page 1

Mesh with different line wire spacings Economic production of industrial mesh for small, medium and large batch sizes The MG950, MG900, MG700 and MG600 together with the Syrocut and OSIWELD systems have been developed for the efficient proP duction of industrial and fencing mesh in small and large batch sizes. The systems are distinguished by high profitability, productivity and easy maintenance. A large selection of extra modules means they can be adapted to different requirements, while allowing a modular setup of the automation level.

Open the catalog to page 2

Everything from a single source The MG950, MG900, MG700 and MG600 together with the Syrocut and POSIWELD systems enable the production of industrial and fencing meshes with different geometries in small to large batch sizes at competitive prices. The modular principle allows customers to start with a cost-effective, simple, yet extendible system. The wide range of extra modules and options guarantees extension up to a fully automatic production system with minimum need for personnel. Thanks to the modular extension options, the systems can be used in both up-and-coming and established...

Open the catalog to page 3

Extendibility with modular principle The right concept for individual requirements: The modular structure of the Schlatter welding systems lets you start with minimum investment costs and further extending your plant in line with requirements. J System MG950, MG900 Welding machines of the MG950 and MG900 system are suitable for the production of industrial mesh and work with precut line and cross wires, with the option of working with flat profiles as well as welding frames with center bars. System MG700 Welding machines of the MG700 system are designed for the production of fencing mesh....

Open the catalog to page 4

Choice of potential system configurations MG950 Line wire feeder; welding machine; cross wire feeder; programmable linear extraction system MG950 Automatic line wire feeder; welding machine; cross wire feeding device with integrated Syrocut straightening-cutting machine; programmable linear extraction system; mesh stacking unit MG700 Automatic line wire feeder; welding machine; cross wire feeding for cross wires from above, cross wire feeding for cross wires from below; programmable linear extraction system; mesh stacking unit

Open the catalog to page 5

Technical data MG950, MG900, MG700 and MG600 are flexible mesh welding systems for economical production of lightweight and heavy standard mesh as well as lightweight customized mesh in small and medium batch sizes. ) Extendible level of automation The line and cross wires are fed via manual or semiautomatic feeding systems, depending on the type of machine. An automatic line wire loading can be used for larger series. A straightening and cutting unit is available with the Syrocut system. This can be integrated into any system, thereby enabling production with wire from a coil, spool or...

Open the catalog to page 6

Shopping trolley With the MG900, Schlatter offers a flexible welding system for the economical production of various types of quality mesh, which may be used for both small series and larger batches. The system is distinguished by high productivity, easy operation and maintenance as well as short tooling times. Thanks to its tremendous flexibility, the MG900 can be set up optimally to the needs of the market. Properties • Welding performance that can be installed corresponding to requirements • ndividually controllable I • Can be extended in varied ways, also with devices for welding frames...

Open the catalog to page 7

MG950 where flexibility, quality and the highest speed is demanded The MG950 is an industrial mesh welding system which is used everywhere where great flexibility, speed and the highest quality is required from the first mesh. Flexibility The highly flexible single welding groups with a width of less than 50 mm (2.0 in) and a straightforward possibility of connection to two independent circuits make extremely productive manufacture of very complex meshes possible in the smallest batch sizes. Speed Cycle speeds of up to 170 wires per minute and two efficient direct current medium frequency...

Open the catalog to page 8

Cable tray system Deck mesh system Highest quality Product characteristics Wire material The positioning of the very stable line wire feeds is supported by a very precise measurement system. The operating software determines the correct welding parameters. In this way the necessary quality for sale of the mesh is attained as soon as the first mesh produced following conversion. Mesh width 200 - 1700 mm (7.9 - 66.9 in) Mesh length 300 - 4000 mm (11.8 - 157.5 in) Wire diameter 2.0 - 8.0 mm (0.08 - 0.31 in) Line wire spacing min. 20 mm (0.8 in) Cold-rolled or -drawn uncoated wire Cold-drawn...

Open the catalog to page 9

Chicken cage MG600 for large batch sizes The MG600 system is suitable for areas of application where large series of the same mesh must be manufactured. The industrial mesh is produced with line wire feeding directly from the coil, spool or reel. Products • Animal cages • Chicken cages • Standard mesh • Storage mesh • Gabions

Open the catalog to page 10

3D wire mesh fence MG700 for all types of standard mesh fences The MG700 fence wire welding systems from Schlatter are suitable for the competitive production of dimensionally accurate meshes in small to large batch sizes. The wires can be straightened and cut in the system or fed directly from the coil. Products • Safety and security fences • 3D wire mesh fences • Dual-wire fences • Privacy fences • Mobile building site fences • Industrial mesh Fence production with pre

Open the catalog to page 11

System Syrocut Direct integration into the cross wire magazine Syrocut system for highly productive straightening and cutting of wires The Syrocut system consists of a synchronously operating spinner straightening machine, a cutting unit and a powered coil-off. The length of each individual wire can be programmed ndividually. i The system can be integrated into the Schlatter mesh welding m achines for line and cross wire feeding. Alternatively it can be used as an ndependent unit. i Syrocut integration into mesh welding machine cross and line wires • Feeding of long thin wires • Wire length...

Open the catalog to page 12All Schlatter catalogs and technical brochures

-

System POSIWELD

2 Pages

-

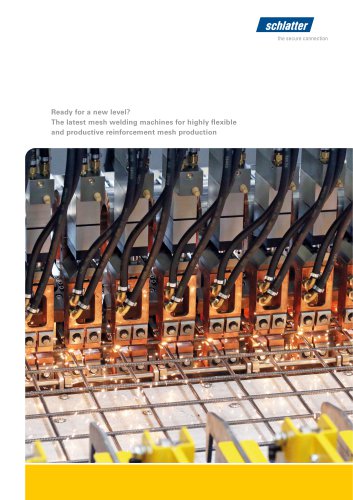

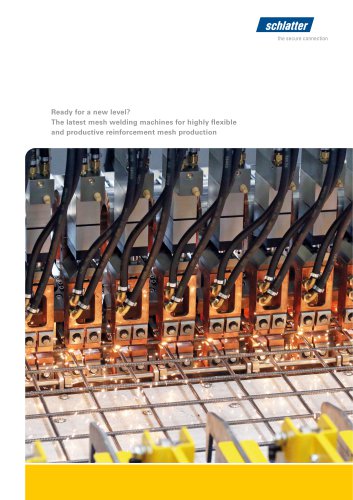

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

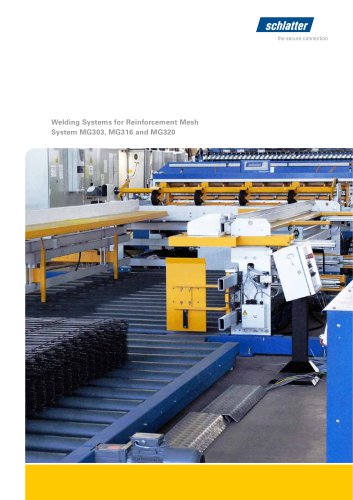

MG300

12 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

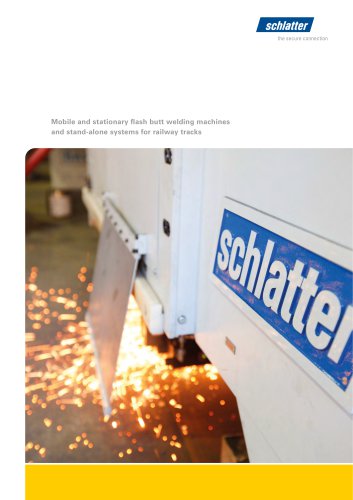

NS200 / NS240

8 Pages

-

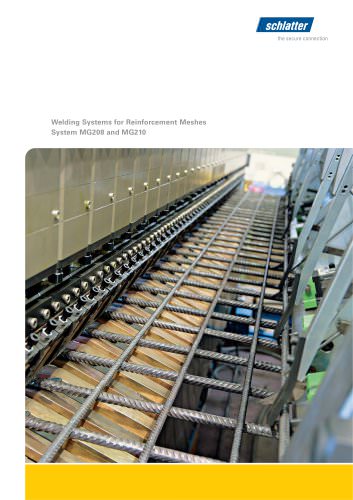

System MG208 and MG210

12 Pages

-

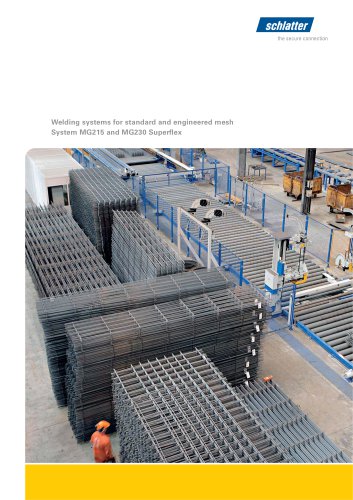

System MG215 and MG230 Superflex

12 Pages

-

6.102EN_BB_Gitterwebmaschine

8 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages