Catalog excerpts

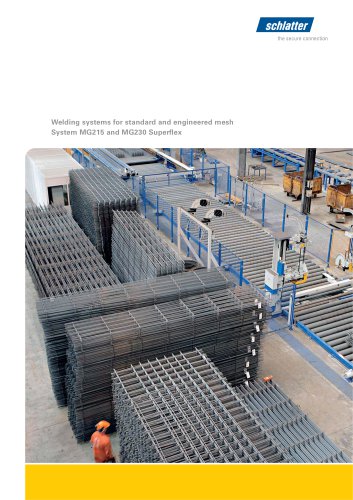

Welding systems for standard and engineered mesh

Open the catalog to page 1

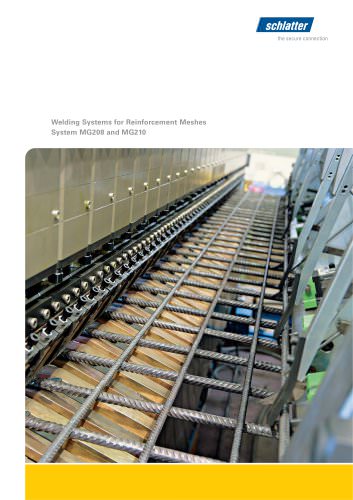

Welding of heavy line and cross wires Economic production of reinforcement mesh – in small batch sizes The Schlatter welding systems MG215 and MG230 Superex are designed for the efficient production of simple and complex reinforcement meshes (standard and engineered meshes) in small and large batch sizes from cold and hot-rolled material. The systems are distinguished by high availability, user friendliness and easy maintenance. A large selection of extra modules means they can be adapted to different requirements, while allowing a modular setup of the automation level.

Open the catalog to page 2

Everything from a single source The MG215 and MG230 Superex systems enable the production of reinforcement meshes with different geometries in small and large batch sizes at competitive prices. Thanks to the modular extension options, the systems can be used in both up-andcoming and established markets. It is not unusual for an MG215 or MG230 project to result in a complete factory, planned, installed and nally handed over to the customer by Schlatter as a turn-key system. Depending on your investment options and the required degree of automation, Schlatter offers a complete solution from a...

Open the catalog to page 3

Extendibility with modular principle The right concept for individual requirements: The modular structure of the Schlatter welding systems lets you start with minimum investment costs. Then allowing you to convert or extend your plant in line with requirements. System MG215 Welding machines of the MG215 system are set up with permanently installed welding presses in a predetermined pattern. Within the selected grid, the mesh geometry can be entered easily at the control unit or called up from a database. System MG230 Superex Welding machines of the MG230 Superex system are equipped with...

Open the catalog to page 4

Choice of potential system congurations MG215 Manual line wire feed; welding machine with fixed welding presses; mesh roller extraction; mesh stacking unit with linear insertion MG230 Superflex Semi-automatic line wire feed with vibration table and linear feed for line wires; welding machine with powered adjustable presses; servo line wire feed; mesh pull-out; mesh stacking unit

Open the catalog to page 5

Technical Data Product features MG215 and MG230 Superex are exible mesh welding systems for the economic production of simple and complex reinforcement meshes (standard and engineered mesh) in small and large batch sizes. Extendible level of automation The line and cross wires are aligned and transported to the system after being cut to length. The line wires are fed in via manual or semi-automatic feeding systems. An automatic line wire loading Mesh widths / Spacing of outermost line wires Mesh lengths Line wire division Cross wire division, innite beyond Line wire diameter Cross wire...

Open the catalog to page 6

Vertically-floating suspended welding presses ensure a reproducible weld quality Wire material • Cold-rolled, smooth or ribbed wire • Hot-rolled wire, micro-alloyed, ribbed • Hot-rolled and subsequently stretched wire, ribbed • Hot-rolled wire with cooling and tempering process directly after rolling (Tempcore), ribbed Depending on the automation required, the straightening and cutting system Syrocut can be integrated.

Open the catalog to page 7

Designed with changing needs in mind Schlatter offers a wide range of extra modules, which can usually also be integrated in existing systems later on. The following options represent a selection of our range for the MG215 and MG230 Superex systems. We would be pleased to advise you in person if you require customized extensions.

Open the catalog to page 8

Cross wire magazine For dual-track mesh production Cross wire dual-magazine For two different wire diameters within the same reinforcement mesh Position-accurate line wire provision Directly from the coil, spool or reel after integration of the straightening and cutting unit system Syrocut Longitudinal chain table For feeding the wires transversely Line wire vibration table For wire-bundle distribution Line wire picker For automatic loading

Open the catalog to page 9

Individual line wire cutter For economic production of short reinforcement meshes Mesh stacker For stacking lightweight and heavy meshes; the precise stacking enables automatic further processing, if required Automatic mesh turning and stacking unit To save transport costs, the meshes are partially turned and stacked Automatic binding unit The automatic binding of the mesh stack makes the production process more efficient Mesh package stacker The mesh package stacker speeds up and automates the logistics at the end of the production process

Open the catalog to page 10

Customer service Investment certainty through long-term support The aim of our work is to increase the productivity of our customers and extend the service life of their systems. Our customer service will therefore continue to provide support after your system has been commissioned. We shall be pleased to arrange a personal discussion and work out a service package customised to your requirements. Repair Service Our multilingual Helpdesk team is available – by phone or via the Internet – to answer general technical questions and provide troubleshooting help for faults or malfunctions in...

Open the catalog to page 11

A reliable partner in plant construction The Schlatter group is a world leader in plant manufacturing for resistance welding systems and weaving machines for special applications. With longstanding expertise in industrial engineering, innovative air and a reliable customer service, the company group listed in Switzerland provides production systems offering high performance and quality. Core competence Weaving segment Schlatter has almost 100 years of expertise in plant construction, customer-oriented solutions, a worldwide presence and more than 500 dedicated employees. The combination of...

Open the catalog to page 12All Schlatter catalogs and technical brochures

-

System POSIWELD

2 Pages

-

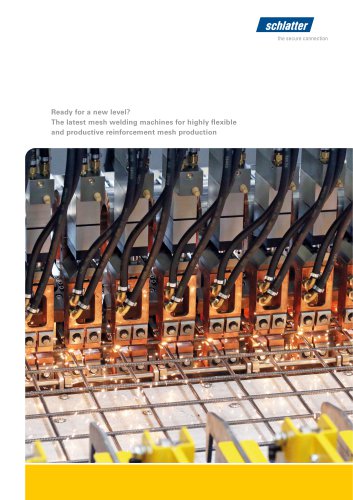

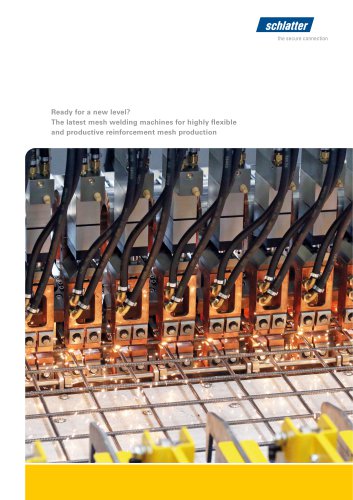

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

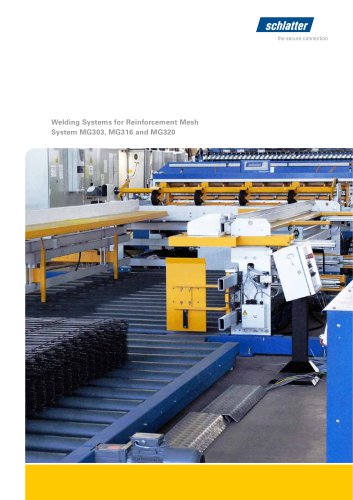

MG300

12 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

NS200 / NS240

8 Pages

-

System MG208 and MG210

12 Pages

-

6.102EN_BB_Gitterwebmaschine

8 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages