Catalog excerpts

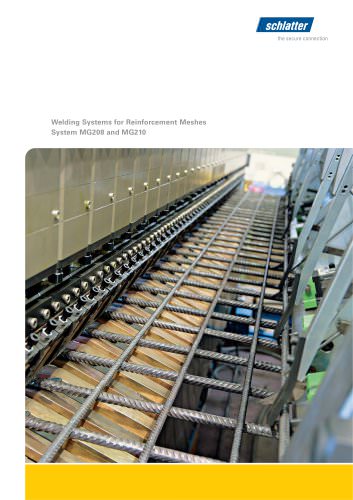

Welding Systems for Reinforcement Meshes

Open the catalog to page 1

Welding of heavy line and cross wires Economical production systems for reinforcement meshes The Schlatter welding systems MG208 and MG210 are designed for high economic viability. The systems are distinguished by low investment costs, user friendliness and easy maintenance. A large selection of extra modules allow to be adapted to different requirements, while allowing a modular setup of the automation level.

Open the catalog to page 2

Everything from a single source The MG208 and MG210 systems enable the production of reinforcement meshes in different geometries at competitive prices. Thanks to the modular extension options, the systems can be used in both, developing and established markets. The modular principle allows customers to start with a low cost, simple yet extendible system. The wide range of extra modules and options allows the upgrade to an automatic production system with minimum need for personnel. The choice of various cross wire feeding systems, plant concepts with very short change over times and high...

Open the catalog to page 3

Extendibility with modular concept The right concept for individual requirements: The modular structure of the Schlatter welding systems lets you start with minimum investment costs before converting and extending your plant in line with requirements. The right concept for the successful start-up of reinforcing mesh production due to low investment cost, easy operation and maintenance. The plant allows a exible operation and can be adapted in an optimal way to the requirements of the reinforcing mesh industry. A variety of additional modules allows the upgrade of the plant at a later date....

Open the catalog to page 4

Choice of potential system congurations MG208 Manual line wire preloading; welding machine with pneumatic line wire feed; mesh roller extraction MG208 Semi-automatic line wire preloading; welding machine with servo line wire feed; mesh roller extraction MG208 Semi-automatic line wire preloading; welding machine with servo line wire feed; mesh turning and stacking unit MG210 Semi-automatic line wire pickup; welding machine, line wire guides; mesh linear pull-out with programmable servo drive; mesh turning and stacking unit MG210 Fully-automatic line wire pickup from wire vibration table and...

Open the catalog to page 5

Technical Data Product features MG208 and MG210 are exible mesh welding systems for economical production of lightweight and heavy standard meshes as well as engineered meshes in small and medium batch sizes. Extendible level of automation The line and cross wires are straightened and cut to length. The line wires are fed in via manual or semi-automatic feeding systems. An automatic line wire loading with robotic grippers can be used for larger series. Depending on the equipment, the production of meshes with longitudinally offset line wires as well as double line wire meshes is also...

Open the catalog to page 6

Line wire infeed Line wire limit stop Wire material • Cold-rolled wire, plain or ribbed • Hot-rolled ribbed wire with inline heat treatment, Tempcore (cooling and tempering process, directly after rolling) • Hot-rolled wire, micro-alloyed, ribbed • Hot-rolled and subsequently stretched wire, ribbed

Open the catalog to page 7

Designed with changing needs in mind Schlatter offers a wide range of extra modules. Most of them can be integrated into existing plants. The following options represent a selection of our range for the MG208/210 system. We shall be pleased to advise you in person if you require customised extensions.

Open the catalog to page 8

Line wire feeders Manual line wire feeder Wire preloading for the next mesh during production Cross wire feeding system With integrated straightening and cutting system Syrocut II Line wire storage table With chain cross-transfer and vibration function Automatic line wire picking and feeding With automatic robotic grippers for picking up line wires from the wire delivery table and feeding the wires to the welding line Line wire advance feeding systems Programmable clamping-pushing drive VariStep With clamping elements and servo drive Mesh linear pull-out After the welding machine, with mesh...

Open the catalog to page 9

Reduced set up time / Increased productivity Cross wire feeding system Chain insertion in opposite direction to production; optionally with motorised adjustment of the chain elements and side guidance for reducing the set up time Single welding groups For xed line wire positions; individually selectable; stroke can be adjusted Turning and stacking / Preparation and further transport of the meshes Automatic mesh turning and stacking unit With roller or linear insertion via grippers Automatic mesh package stacker Stacks tied mesh packages Automatic tying unit Consists of two units; tying is...

Open the catalog to page 10

Customer service Investment certainty through long-term support The aim of our work is to increase the productivity of our customers and extend the service life of their systems. Our customer service will therefore continue to provide support after your system has been commissioned. We shall be pleased to arrange a personal discussion and work out a service package customised to your requirements. Repair Service Our multilingual Helpdesk team is available – by phone or via the Internet – to answer general technical questions and provide troubleshooting help for faults or malfunctions in...

Open the catalog to page 11

A reliable partner in plant construction The Schlatter group is a world leader in plant manufacturing for resistance welding systems and weaving machines for special applications. With longstanding expertise in industrial engineering, innovative air and a reliable customer service, the company group listed in Switzerland provides production systems offering high performance and quality. Core competence Weaving segment Schlatter has almost 100 years of expertise in plant construction, customer-oriented solutions, a worldwide presence and more than 500 dedicated employees. The combination of...

Open the catalog to page 12All Schlatter catalogs and technical brochures

-

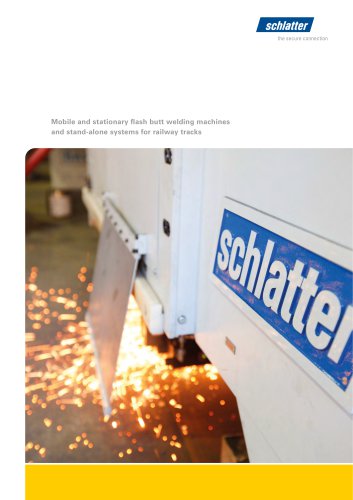

System POSIWELD

2 Pages

-

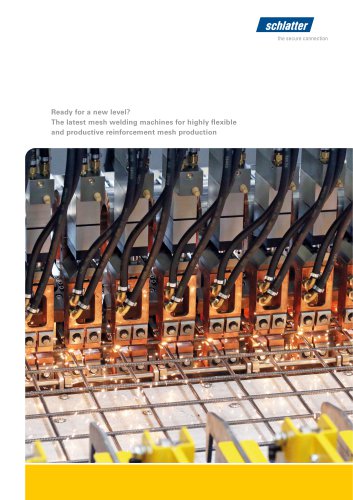

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

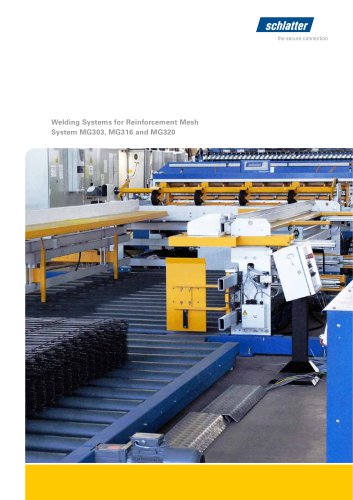

MG300

12 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

NS200 / NS240

8 Pages

-

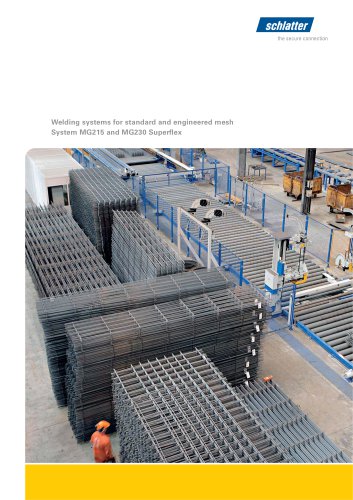

System MG215 and MG230 Superflex

12 Pages

-

6.102EN_BB_Gitterwebmaschine

8 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages