Catalog excerpts

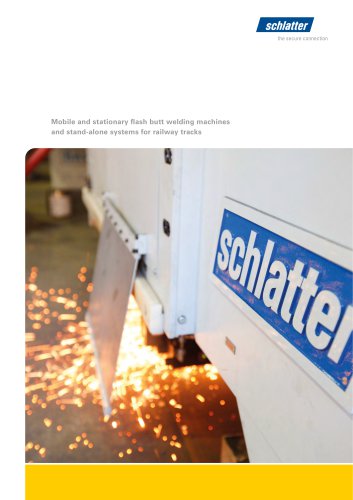

Mobile and stationary flash butt welding machines and stand-alone systems for railway tracks

Open the catalog to page 1

Efficiency and reliability with the help of flash butt welding Flash butt welding is the most reliable joining technology for track construction and it is a proven fact that it provides the lowest failure frequency. Schlatter offers welding machines that run in different customized systems. Welding machines and systems Mobile rail welding systems Stationary rail welding systems Worldwide flash butt welding has become increasingly popular for production of continuous welded rails. With the help of the mobile welding systems, continuous track sections are produced directly in-track....

Open the catalog to page 2

Stationary welding machines Stationary rail welding machines GAAS80 and GAA100 System GAAS80 The GAAS80 welds short rails of any length to long welded rails up to 500 m lengths and even longer. Its main feature is the exact lateral alignment of the running edge and vertical alignment of the running surface. The web clamping device is independent from the electrodes and it ensures the rails do not slip during upsetting. Directly after completion of the welding process the integrated deburring device removes the burr. System GAA100 The GAA100 is used for welding components in turnout...

Open the catalog to page 3

Mobile welding machines Mobile rail welding machines AMS60, AMS100 and AMS200 The mobile rail welding machines AMS60, AMS100 and AMS200 have different characteristics and the right machine can be selected depending on the required operation purpose. Regardless of the welding machine, there are several various system solutions to choose from. Welding machines In particular, the welding machines AMS60, AMS100 and AMS200 differ in alignment systems and operating ranges. AMS200 is also designed to perform the "last" welding, i.e. to complete distressing and welding in a single operation. The...

Open the catalog to page 4

Mobile welding machines System AMS100 AMS100 for bigger rail profiles. The AMS100 features a lot more welding force than the AMS60 and thus it allows welding of heavy rail profiles and even grooved rails. It is often used for welding of freight train track where heavy rails are used. Nevertheless the AMS100 has also welded in high-speed lines in various projects and passed the respective homologation processes successfully. System AMS200 System AMS200 for closure welds and distressing. The AMS200 is the latest development in mobile rail welding machines, a new generation which enables the...

Open the catalog to page 5

Mobile rail welding systems Mobile rail welding systems Supra Multiflex and Supra Roadflex For mobile welding of continuous welded rails, these machines are normally integrated into an autonomously operating rail welding system. These systems are equipped with diesel-generator set, hydraulic unit, cooling unit and lifting device. Supra Multiflex container-based rail welding system Supra Roadflex truck-based rail welding system Container systems are especially suitable for welding continuous welded rails directly in new railway track. They are also often used semi-stationary in the depot or...

Open the catalog to page 6

Control unit and Weld Analyzer Supra Roadflex Supra Roadflex systems are self-propelled, they can work completely autonomously and they are very flexible for moving from one job site to the next. Going into track is carried out on any level crossing that requires little space. Shortly afterwards the system is ready for welding at the job site. Control unit and Schlatter Weld Analyzer The control system of stationary and mobile machines comprises the function control (PLC), the weld processor and the Schlatter Weld Analyzer. The latest generation of the Schlatter Weld Analyzer contributes...

Open the catalog to page 7

A reliable partner in plant construction The Schlatter Group is a world leader in plant manufacturing for resistance welding systems for specialized solution in the field as well as weaving and finishing machines for paper machine clothing, wire and mesh. With our long-standing expertise in industrial engineering, our spirit of innovation and our reliable customer service we offer our customers high-performance and high-quality manufacturing systems. Experience in plant design Weaving segment The combined competence in the fields of welding, weaving and industrial engineering makes the...

Open the catalog to page 8All Schlatter catalogs and technical brochures

-

System POSIWELD

2 Pages

-

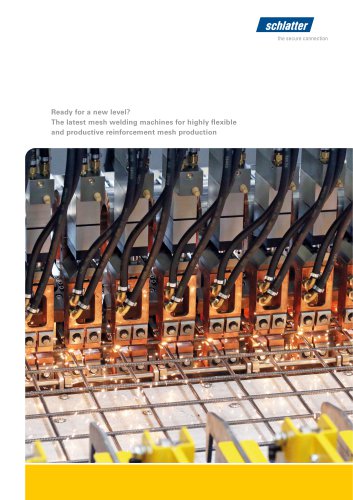

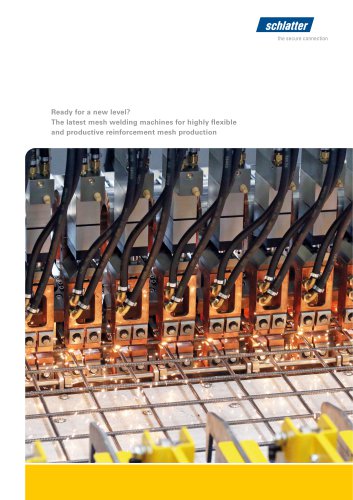

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

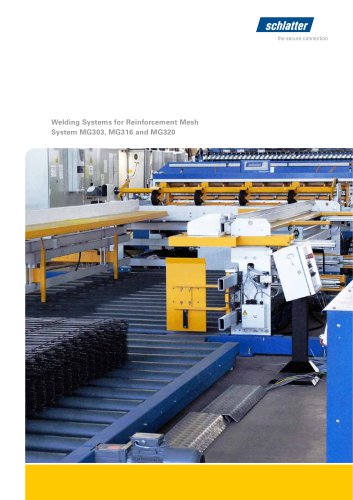

MG300

12 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

NS200 / NS240

8 Pages

-

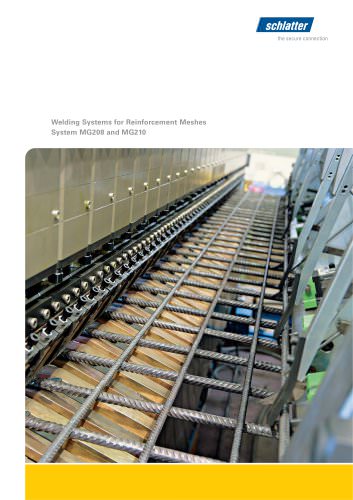

System MG208 and MG210

12 Pages

-

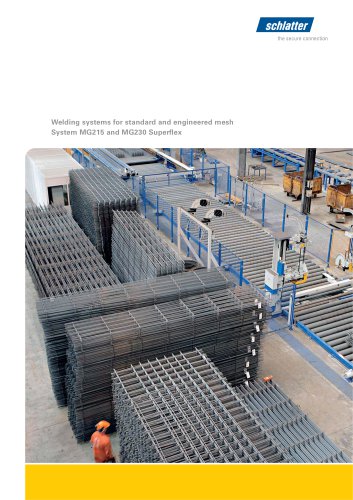

System MG215 and MG230 Superflex

12 Pages

-

6.102EN_BB_Gitterwebmaschine

8 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages