Catalog excerpts

High Performance Mesh Welding System for Light Wire Mesh System NS200 and NS240

Open the catalog to page 1

Mesh width Mesh length Line wire division Cross wire division Line wire diameter Cross wire diameter Number of cross wires / min. Line wire and cross wire feeding Further dimensions on request The mesh welding systems NS200 and NS240 are suitable for the manufacture of light welded mesh as rolled mesh or panels. NS200 customer specifications customer specifications up to 100 at feeding of single wires up to 220 up to 170 at feeding of double wires from spools, coils or reels from spools, coils or reels

Open the catalog to page 2

Low operating costs The operating costs can be kept low by exclusively using servo and electrical components as well as cam-controlled welding presses. The state of the art NS200 and NS240 lines are equipped with a medium frequency welding technology (MF). The mesh is manufactured with line wire and cross wire feed directly from spools, coils or reels. No additional straightening and cutting to length machines is necessary. State of the art control The entire process is assured by using a state of the art PLC (Programmable Logic Controller). Simple operation and visualisation is carried out...

Open the catalog to page 3

Mesh advance with rubberised 3-roller system NS200 high performance mesh welding system for fine wire mesh of 0,5 – 2,5 mm The NS200 is a mesh welding system for fine welded mesh providing highest product quality and performance. The cross wires are fed - according to specification - either with single wire or double wire feed with a special transport and oscillating gripper of the respective electrode level. Mesh is pulled out with a rubberised 3-roller system which is positioned behind the welding portal. This enables continuous divisions.

Open the catalog to page 4

Characteristics • Line and cross wire feed from spools, coils and reels • Transport grippers for cross wire draw off • Oscillating grippers for the transport of the cross wire into the electrode level • Controlled mesh advance with rubberised 3-roller system guarantees the highest degree of precision • Rotating shears for trimming and separating the mesh into several strips • Coiler with expansion mandrel and integrated shears • Intermediate storage for continuous production during exchange of roller • Oscillating welding traverse with pneumatically adjustable welding presses • State of the...

Open the catalog to page 5

Cross wire disc feed NS240 for an extensive variety of application The NS240 system is a mesh wire welding system with cross wire double feed and disc insertion providing maximum reliability. A consistently used modular system for the individual system components allows for the provision of a perfect system for each intended application purpose. The mesh advance is carried out by two continuously working gripper combs. This ensures the production of top quality mesh.

Open the catalog to page 6

Characteristics • Line and cross wire feed from spools, coils and reels • Straightening elements centrally adjustable for fast adjustment to different wire diameters • Double cross wire feed, enables high cycle speeds • Servo electric cross wire shears • Cross wire feed with disc insertion • Rotating shears for trimming and separating • Continuous mesh transport with two gripper combs • High performance shears for cutting the line wires for wire mesh production • Stacking unit designed for continuous high production speeds without interruption of production • Semi- and fully-automatic...

Open the catalog to page 7

A reliable partner in plant construction the secure connection ( The Schlatter Group is a world leader in plant manufacturing for resistance welding systems for specialized solution in the field as well as weaving and finishing machines for paper machine clothing, wire and mesh. With our long-standing expertise in industrial engineering, our spirit of innovation and our reliable customer service we offer our customers high-performance and high-quality manufacturing systems. Concept by Schlatter Industries AG 4.164EN BG Experience in plant design The combined competence in the fields of...

Open the catalog to page 8All Schlatter catalogs and technical brochures

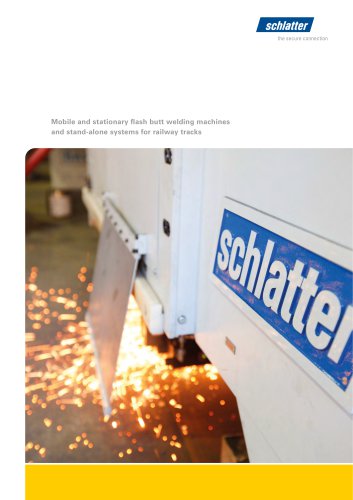

-

System POSIWELD

2 Pages

-

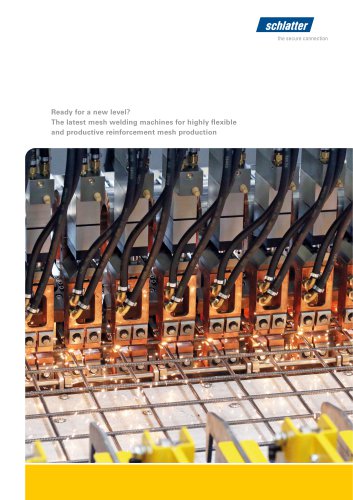

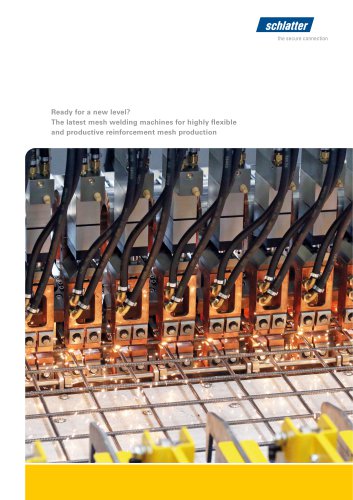

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

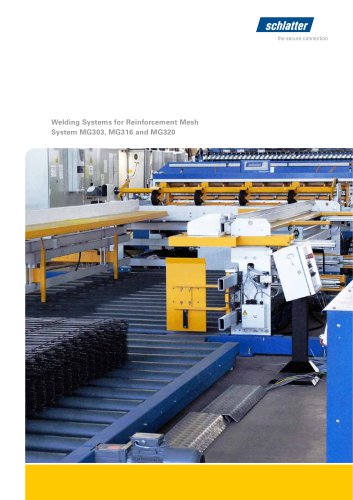

MG300

12 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

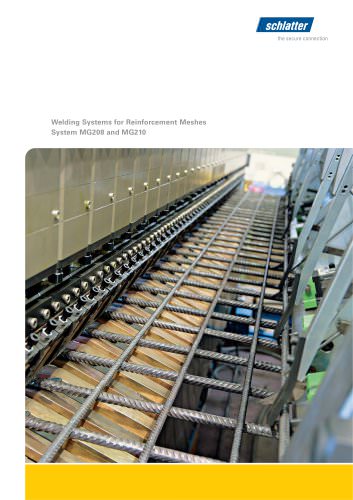

System MG208 and MG210

12 Pages

-

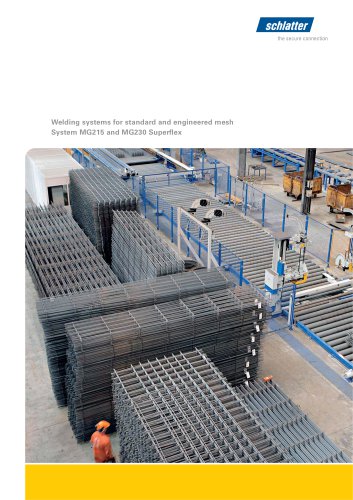

System MG215 and MG230 Superflex

12 Pages

-

6.102EN_BB_Gitterwebmaschine

8 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages