Catalog excerpts

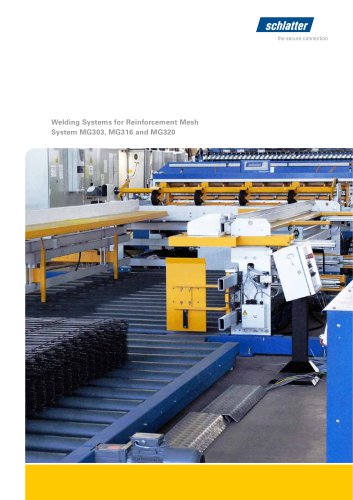

Welding Systems for Reinforcement Mesh System MG303, MG316 and MG320

Open the catalog to page 1

Shear for cutting line wires Economical production systems for reinforcement mesh The Schlatter welding systems MG303, MG316 and MG320 are designed for high economic viability. The systems are characterized by high productivity, low operating costs and ease of operation. A large selection of extra modules means they can be adapted to different r equirements, while allowing a modular setup of the automation level.

Open the catalog to page 2

Everything from a single source The systems of the MG300 series enable the production of reinforcement mesh in different geometries at competitive prices. Thanks to the modular extension options, the systems can be used in both developing and established markets. The modular principle allows customers to start with a cost-effective, simple yet extendible system. The wide range of extra modules and options guarantees extension up to an automatic production system with minimum need for personnel. The choice of various cross wire feeds allows for the implementation of system concepts with...

Open the catalog to page 3

Extendibility with modular principle The right concept for individual requirements: The modular structure of the Schlatter welding systems allows you to start with minimum investment costs. This allows to convert or extend your plant in line with your requirements. J System MG303 This system concept is ideally suitable for the economic production of lightweight and heavy standard mesh in medium and large batches. The line wires are drawn off by spools, coils or reels. The cross wires are straightened, cut to length and fed to the welding system from a large magazine. This allows the system...

Open the catalog to page 4

Choice of potential system configurations MG303 Line wire feed from spools, coils or reels; straightening units, line wire pull-off and compensating mechanism; welding machine with roller advance feed; cross wire disc feed; line wire shear; mesh turning and stacking unit MG303 Line wire feed from spools, coils or reels; straightening units; line wire pull-off and compensating mechanism; roller advance feed; cross wire disc feed; welding machine; line wire shear; mesh turning and stacking unit MG316d Line wire feed from spools, coils or reels; straightening units; line wire pull-off and...

Open the catalog to page 5

Technical Data MG303, MG316 and MG320 are flexible mesh welding systems for the economic production of lightweight and heavy mesh in large series batches. J Extendible level of automation The MG303 system can be extended by integrating the Syrocut system in the cross wire feed, which is a straightening and cutting machine. In addition, all systems of the MG300 series can be extended with a labelling machine, a binding unit and a mesh package stacker. Mesh width / Spacing of outermost line wires Mesh lengths Line wire division mind. 50 mm infinite beyond mind. 50 mm infinite beyond mind. 50...

Open the catalog to page 6

Line wire straightening elements Wire material • Cold-rolled, smooth or ribbed wire • Hot-rolled wire with cooling and t empering process directly after r olling (Tempcore), ribbed • Hot-rolled wire, micro-alloyed, ribbed • Hot-rolled and subsequently stretched

Open the catalog to page 7

Schlatter offers a wide range of extra modules, which can usually also be integrated in existing systems later on. The following options represent a selection of our range for the MG300 systems. We would be pleased to advise you in person should you require customized extensions. ) Line wire straightening and advance feed systems Line wire pull-off Horizontal and vertical pull-off for spools or coils Line wire monitoring The device monitors the line wires and switches the system off in the event of a wire break or at the line wire end Pull-off and straightening of the line wires...

Open the catalog to page 8

Line wire pull-off and compensating mechanism Each line wire is monitored individually Line wire roller advance feed The roller advance feed serves to feed the line wires in order to create the cross wire divisions; the cross wire spacing is freely programmable Welding machines Welding portal for MG303 and MG316e With pneumatic, soft-contact high-performance presses and cube electrodes Welding portal for MG316d The predetermined 50 mm interval between the single welding groups precludes any line wire spacing adjustments

Open the catalog to page 9

Cross wire feeds Cross wire feed with gripper The gripper positions the cross wire above and below the line wire into the welding line Cross wire feed with disc Wire feed in direction of production; with disc insertion for high cycle speed Magazine for cross wire feed with magnetic drum For separating off cross wires from large wire bundles Cross wire feed With automatic cross wire changing system and loop storage system, a welding machine, line wire shear and roller advance feed Automatic cross wire changing system Minimum downtime when changing the spools (20–30 seconds), no time lost due...

Open the catalog to page 10

Customer service Investment certainty through long-term support ( Our goal is to increase our customers' productivity and to extend their systems' service life. This is why our customer service will continue to provide support even after your Schlatter systems have taken up operation. We will be happy to arrange a personal consultation meeting and work out a custom-tailored service package for you. You can contact our customer service T +41 44 732 74 20 service@schlattergroup.com Spare Parts and Repair Service MySchlatter.com T +41 44 732 71 11 spareparts@schlattergroup.com Service...

Open the catalog to page 11

A reliable partner in plant construction The Schlatter Group is a world leader in plant manufacturing for resistance welding systems for specialized solution in the field as well as weaving and finishing machines for paper machine clothing, wire and mesh. With our long-standing expertise in industrial engineering, our spirit of innovation and our reliable customer service we offer our customers highperformance and high-quality manufacturing systems. Experience in plant design Weaving segment The combined competence in the fields of welding, weaving and industrial engineering makes the...

Open the catalog to page 12All Schlatter catalogs and technical brochures

-

System POSIWELD

2 Pages

-

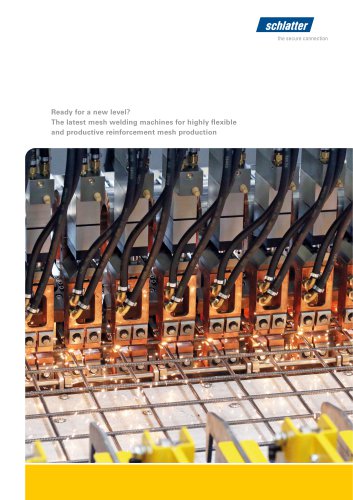

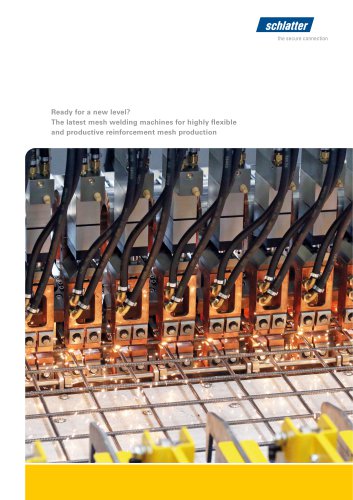

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

NS200 / NS240

8 Pages

-

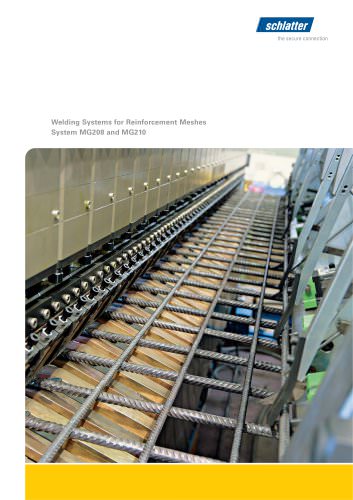

System MG208 and MG210

12 Pages

-

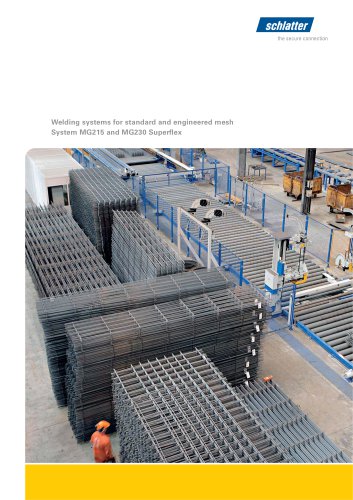

System MG215 and MG230 Superflex

12 Pages

-

6.102EN_BB_Gitterwebmaschine

8 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages