Catalog excerpts

Screen Assembly Machines/Wire Crimping Machines

Open the catalog to page 1

Application range Machines for the production of high-quality screens The Jàger screen assembly machines of Schlatter Deutschland are designed for high economy and for highest-quality screens. The machines are characterized by their operator convenience and easy maintenance. A number of peripheral devices complete the necessary equipment for economic production of metal screens. The screen assembly machines of the type RG and GD are very robust weaving machines and cover the entire market of heavy sieve fabrics.They enable the production of different screen geometries in small to large lot...

Open the catalog to page 2

Product program screen assembly machines 3 The optimum configuration of the screen assembly machine The right concept for individual demands: Due to the modular concept of the Jàger screen assembly machines by Schlatter Deutschland,you start with minimal investment cost and can extend your system according to your needs. RG210 with weft wire crimping GD610 with weft wire crimping Screen assembly machines for the production of fence and security Screen assembly machines for the production of heavy sieves. Weft insertion by direct insertion. Screen assembly machines for the production of...

Open the catalog to page 3

Technical data Screen assembly machines RG210, GD600, GD610 and GD620 are flexible screen assembly machines for the economic production of sieves and screens of Weaving width Wire diameter Mesh width Wire material iron wire, spring steel, stainless steel spring steel, stainless steel spring steel, stainless steel Weft insertion roll insertion direct insertion band gripper system with

Open the catalog to page 4

Wire crimping machines Under the brand Jàger, Schlatter Deutschland offers a large range of additional modules and peripheral devices.The following options represent a selection from our range of goods.The wire crimping machines KM200, KM320 and KMSS are the right complement for the optimum preparation of the warp and weft wires for the Jàger screen assembly machines. Wire diameter max. 8 mm (spring steel) max. 8 mm (spring steel) max. 15 mm (spring steel) Wire diameter max. 7 mm (spring steel) max. 7 mm (spring steel) Wire material spring steel, stainless steel spring steel, stainless...

Open the catalog to page 5

6 Technical data Kinds of screens Whether you require crimp screens or press screens, Schlatter Deutschland offers the corresponding machines and tools for every demand. Crimped Screen with wires in 1st crimp: t=m+d d d d tz d tz d tz Crimped Screen with wires in 5th crimp: t=1/5 (m+d) d d d d d Pressed Screen, wires pressed both sides: t=m+d tz d d tz tz m m d d m m m m m m tz d m d m d m d m d m d m tz d tz m d m d m t t td d t m m d m m dt m td m d t t tz tz tz tz tz tz tz = tooth pitch of crimp or press wheels d tz tz tz tz t t Pressed Screen, wires pressed one side: t=m+d m t t m m d d...

Open the catalog to page 6

Investment protection through sustained support Our aim is to increase the productivity of our customers and to increase the operating life of their machines.Therefore we also provide customer service support after the start-up of a Jàger system. Repair service For general technical questions and repair or maintenance issues, please contact our multilingual helpdeskteam which we can carry out repairs and overhauls to your control devices and mechanic components. Field service Spare part service For prompt help on the spot, our field service specialists offer expert support Thanks to our...

Open the catalog to page 7

A reliable partner in plant construction The Schlatter group is a world leader in plant manufacturing for resistance welding systems and weaving machines for special applications. With long-standing expertise in industrial engineering, innovative flair and a reliable customer service, the Group listed in Switzerland provides production systems offering high performance Core competence Weaving segment of expertise in plant construction The company enjoys a worldwide presence and has more than 500 dedicated employees.The combination of expertise in welding and systems technology makes...

Open the catalog to page 8All Schlatter catalogs and technical brochures

-

System POSIWELD

2 Pages

-

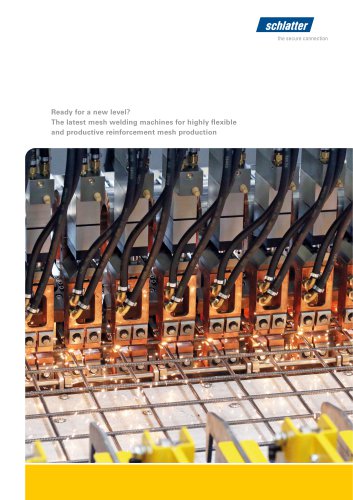

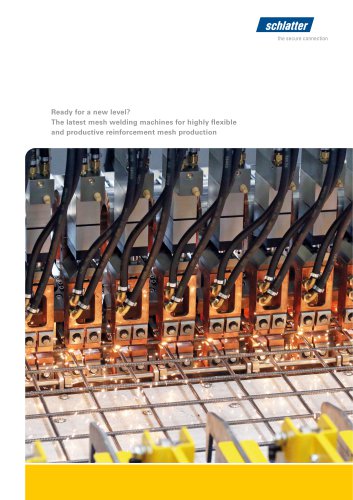

Ready for a new level?

8 Pages

-

MG700

2 Pages

-

MG800

2 Pages

-

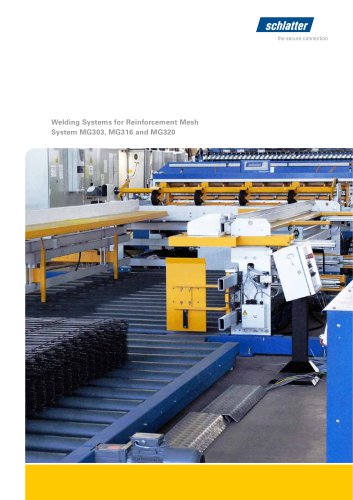

MG300

12 Pages

-

Industrial Mesh Welding Machines

16 Pages

-

Welding Machine System SGK

2 Pages

-

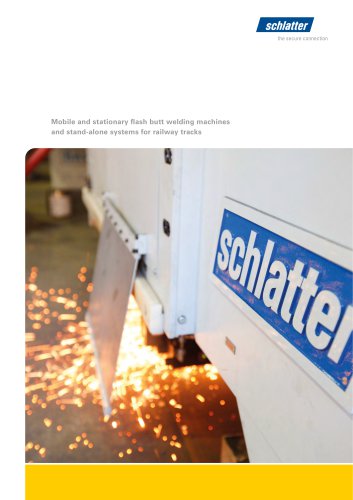

NS200 / NS240

8 Pages

-

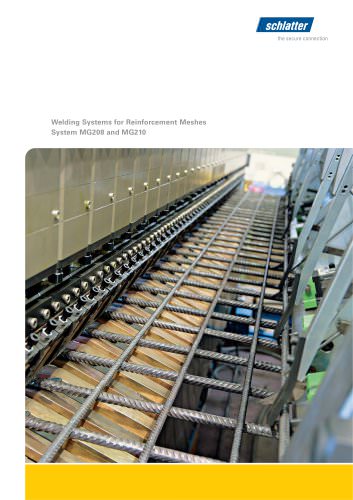

System MG208 and MG210

12 Pages

-

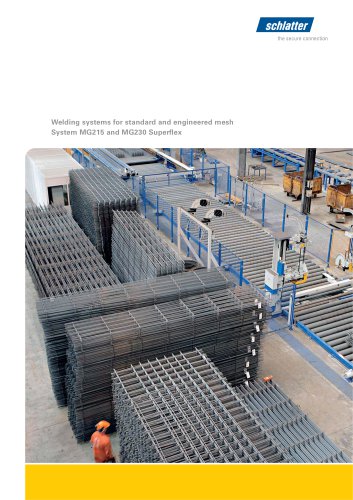

System MG215 and MG230 Superflex

12 Pages

-

6.101EN_BB_Drahtwebmaschine

12 Pages

-

6.103EN_BB_PMC-Weaving

12 Pages