Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

Series UBLD Balancing Machines for Torque Converters • Semi or fully automatic sequence of operations • Interfacing with the production line • Fully automatic unbalance correction Range of application Measurement and correction of the unbalance of torque converters. Application of the machine in large volume production, integrated with the production line and with suitable infeed or outfeed conveyors. Unbalance correction by welding of weights on the outside surface of the converter in one or more correction steps. Weights are obtained fully automatically from coils. At the rear of the machine, a correction weight is cut to size from a metal coil in accordance with the measured unbalance, formed and supplied to the welding unit. The welding unit transfers the correction weight to the work-piece and fastens it by means of one or two spot welds at a defined radius. A medium-frequency welding method is used. Design Single-plane balancing machine with vertical rotor axis and semi or fully automatic sequence of operation. Basic machine with balancing unit and high-precision clamping adapter, weight cutting and forming unit and welding system for unbalance correction. Determination of unbalance, calculation of correction weights and correction control through microprocessorbased measuring unit. Loading and unloading either manually or automatically by means of internal or external transport unit. Freely programmable machine control and machine diagnostic system with display screen. Multi-station models available on request. Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 1

Series UBLD Balancing Machines for Torque Converters The machines have one working station, in which unbalance measurement and correction take place in succession. This simplifies rotor handling, as there is no need to re-clamp the rotor between working steps.For medium volume production, the station can be loaded and unloaded manually by an operator. For larger volumes, the machine is integrated into the production line.Multi-station models in which measurement, correction and inspection are performed in separate stations, are available upon request. 1 2 3 4 5 6 7 8 Torque converters...

Open the catalog to page 2

Technical data at a glance Measuring unit Torque converter, complete Manual loading Automatic loading Automatic unbalance correction (welding) Balancing speed Measuring uncertainty Achievable tolerance Cycle time Power consumption 2) Data non-binding, depending on the respective equipment 3) Depending on work-piece and initial unbalance

Open the catalog to page 3All SCHENCK RoTec GmbH catalogs and technical brochures

-

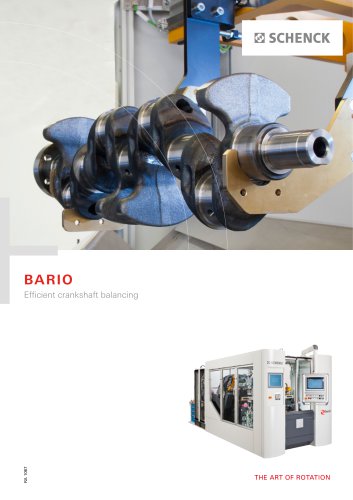

BARIO

7 Pages

-

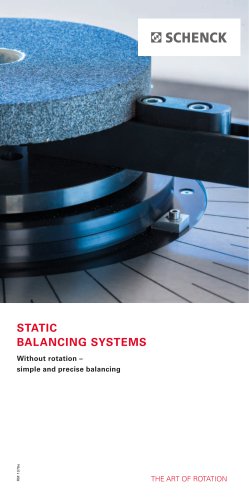

Static Balancing Systems

5 Pages

-

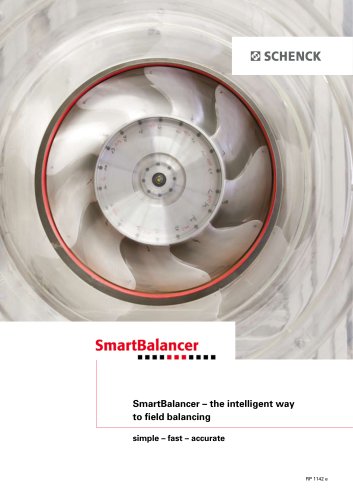

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages