Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

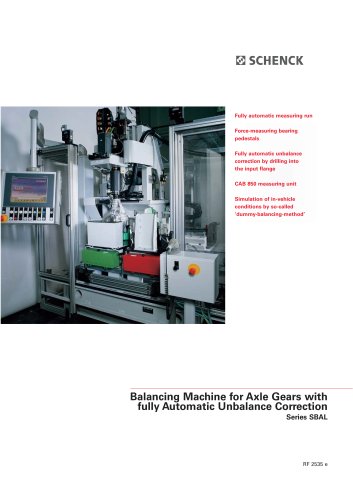

Fully automatic measuring run Force-measuring bearing Fully automatic unbalance correction by drilling into Balancing Machine for Axle Gears with fully Automatic Unbalance Correction Series SBAL

Open the catalog to page 1

Balancing Machine for Axle Gears with fully Automatic Unbalance Correction the unbalance of front and rear Application of the machine in axle gear production. Low-speed measurement of unba- Unbalance correction by drilling into the axle drive input flanges (welding available as option). 5 Drill chip extractor Machine design optimally adapted to the task. Arrangement of machi- ne assemblies based on ergonomie Welded machine base of special design. Hard bearing pedestals with auxiliary balancing frame, adapted especially to the individual axle geometry. Pneumatically operated gear clam- ping...

Open the catalog to page 2

Optical pattern recognition of the input flange for high- precision unbalance correction and detection of forbid- Drive flange with correction hole. Ergonomie PC-based measuring unit withTFT touch screen display. Optimum calculation of unbalance correction masses to be removed by drilling, with direct display. Digital measuring process with high fre- quency selectivity. Compensation circuit for electrical compensation of initial unbalance or adapter unba- Further special features: Large display, operator prompting, diagnostic programs, fault display, statistics program and printer...

Open the catalog to page 3

Important data at a glance 2) Accordinq to DIN 1319, 95% probability, with master rotor and without re-clampinq error 3) Dependinq on initial unbalance and operatinq personnel Diagnosetic Systems SCHENCK RoTec GmbH Tel.:+49 (0) 61 51 - 32 23 11 Make use of our worldwide distribution network. eMail: rotec@schenck.net [PURR] Group

Open the catalog to page 4All SCHENCK RoTec GmbH catalogs and technical brochures

-

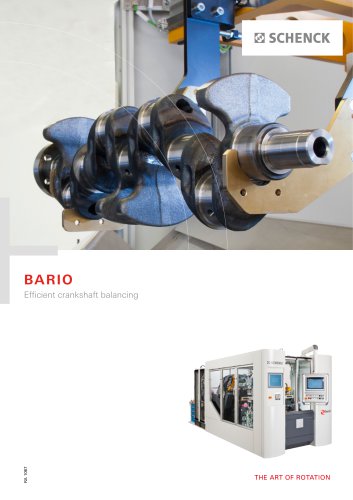

BARIO

7 Pages

-

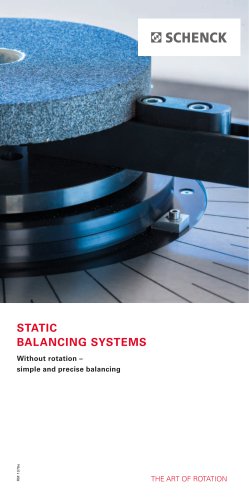

Static Balancing Systems

5 Pages

-

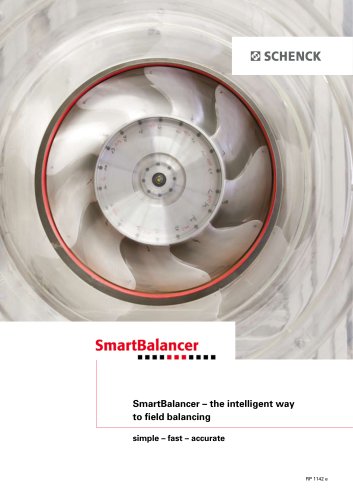

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages