Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

JAC-I/A Balancing and Diagnostic System for Rear-Axle Modules • Balancing of the drive train • Testing the rear axle drive in the installed condition (NVH = Noise vibration harshness,VAD = Vibroacoustic diagnosis) • Function test • Automatic test sequence Range of application Quality testing of drive modules (front-mounted rear-axle with drive shafts) of passenger vehicles and light commercial vehicles. Suitable for measurement and correction of the unbalance, improvement of the NVH characteristics through vibroacoustic evaluation of the assembly structure as well as diagnosis of the noise properties of components (differential, drive shaft, bearing). Application in production, integrated into the assembly line. Design Single-station machine with fully automatic test sequence, loading and unloading by a pallet system. Consisting essentially of vibration isolated machine frame for testing as if installed, measurement and control cabinet with test-stand PC and drive, positioning device for adaptation to the work-piece type on hand, protective enclosure. Sequence of operations • Transport the rear-axle module on pallet by roller conveyor and close the protective equipment (loading door) • Lift the pallet, clamp, couple the drive and synchronizer, attach the sensors for unbalance measurement, lower the pallet, close the safety devices. shaft (with type mix), run up and regulate the load, measure the required torque and differential ratio, measure the initial unbalance, structure-borne sound and the possible test weight and correction positions, brake, index, add the test weight, and carry out a further measuring run, brake, index, remove the test weight, calculate the coefficient and initial unbalance. Compare with tolerances (for coefficient and unbalance). • When out of tolerance: Index for unbalance correction, open the operating doors, manually add the unbalance correction according to the display, close the doors and perform a check run. • When in tolerance: Mark, travel to home position, open loading doors, move the pallet out. Special features • Modular construction as a single station with free positioning of test part (installation position) • Powerful industrial PC for control of the test sequence and measured value processing • Software module for VAD procedure and measurement of • Fully automatic test sequence: Check the length of the drive Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt static unbalance; large rotor type data memory, operator prompting, diagnostic program, statistics, process control, external interfaces Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 1

JAC-I/A Balancing and Diagnostic System for Rear-Axle Modules • Single or multiple-channel noise checking with integrated unbalance recognition • Flexible application, easy change over for various rearaxle modules • Special system adaptation to the requirements of objective noise testing, such as structural isolation of the test equipment as well as high-repeatability, test part coordinated sensor coupling of the test part support. • Automatic coupling of the part at the shaft ends • Automatic recognition of the possible correction position • With manual correction automatic indexing to the...

Open the catalog to page 2

JAC-I/A Balancing and Diagnostic System for Rear-Axle Modules 1 Machine bed2 Drive 3 Slide 4 Adapter 5 Torque measurement shaft 6 Retaining device 7 Clamping device central bearing 8 Clamping device (4x) 9 Lifting unit 10 Palette 11 Synchronisation with brake Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 3

Technical data at a glance Measuring unit Unbalance determination Manual unbalance correction Vibro-acoustic diagnostic Drive simulation through test part loading equipment Rear-axle module, complete Test speed Measurement uncertainty, approx. Cycle time, approx. Power consumption Type identification 2) Acc. to DIN 1319, 95% probabi ity, workpiece dependent 3) Dependent on unbalance correction method and Integration with other equipment 4) Dependent on the selected test speed

Open the catalog to page 4All SCHENCK RoTec GmbH catalogs and technical brochures

-

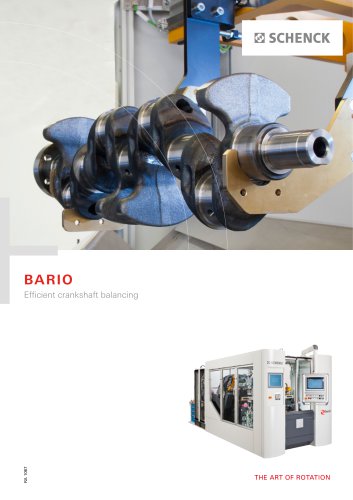

BARIO

7 Pages

-

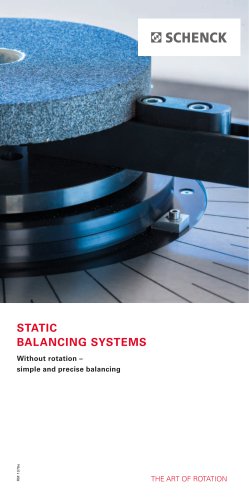

Static Balancing Systems

5 Pages

-

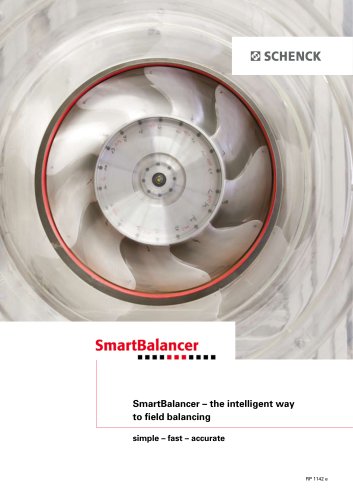

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages