Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

HS 10 - 40, HS 10 Twin Balancing Machines for Small Rotors and Complete Assemblies • Balancing of ready-for-use assemblies without dismantling • Hard-bearing principle provides for high balancing accuracy and quick change-over from one work-piece type to the next • Easy and simple operation • Extensive range of safety equipment for protection classes B und C • Modular structure caters for a variety of different applications Range of application Measurement of the unbalance of complete assemblies such as fan motors in medium to large batches. Designed for standing or seated operator and for use in varying locations. Change-over to a different rotor type can be achieved easily within a minimum of time. Manual unbalance correction by addition of material (e.g. balancing plasticine or metal clips) directly on the machine or by removal of material on optional manually operated or semi automatic machine tools. Design Hard-bearing horizontal balancing machine of table-top design with one or two measuring stations. Designed for standing or seated operator with partly automated sequence of operations. Microprocessor-based measuring instrumentation with permanent calibration. The two bearing pedestals are connected by means of a plate or a frame, accommodating an adapter/clamping device to support the assemblies. The assemblies are driven by their own drive system through an integral power supply. Alternatively external drive by means of compressed air or belt drive can be used. Many assemblies, particularly fans for use in vehicles or domestic appliances, gyroscope rotors or hard disc drives have to be balanced in the fully assembled condition. Even if all individual parts are balanced carefully, assembly of the complete unit will create new unbalances, resulting from manufacturing errors, such as eccentricity, fit tolerances or concentricity errors. Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 1

HS 10 - 40, HS 10 Twin Balancing Machines for Small Rotors and Complete Assemblies The machine concept is particularly variable. Subassemblies are mounted on specially adapted plates which can be interchanged easily. Underslung belt drive can be used universally for a variety of rotors having their own shaft journals. For larger batches, a two-station machine is the optimum solution. The machine can be operated in overlapping cycle, i.e. while the unbalance of one rotor is being corrected, the unbalance of the next one can already be measured.Likewise, the operating and safety concept is...

Open the catalog to page 2

HS 10 - 40, HS 10 Twin Balancing Machines for Small Rotors and Complete Assemblies Technical data at a glance HS 10 HS 10 TWIN HS 20 HS 30 HS 40 CAB 700 CAB 700 CAB 700 CAB 700 CAB 700 Number of measuring stations 1 2 1 1 1 Drive by the rotor´s own drive system • • • • • Protective device as per ISO 7475 • • • • • 16 16 100 700 3000 6 - 70 6 - 70 9 - 140 10 - 160 15 - 240 Measuring unit Rotor Weight, max. [kg] Bearing journal diameter Machine Weight A [mm] 980 980 1260 2620 3160 Depth B [mm] 850 850 1175 2380 2380 Height C [mm] 1520 1520 1465 2245 2245 Bearing cradle height [mm] 105 105 240...

Open the catalog to page 3All SCHENCK RoTec GmbH catalogs and technical brochures

-

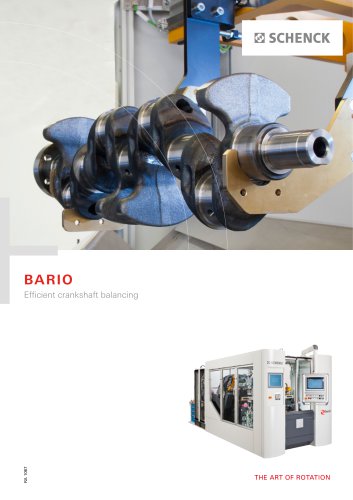

BARIO

7 Pages

-

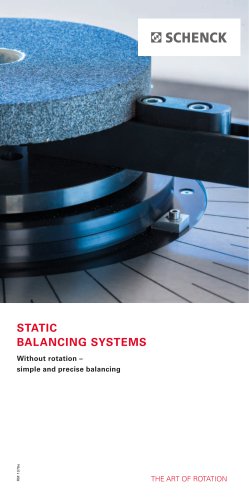

Static Balancing Systems

5 Pages

-

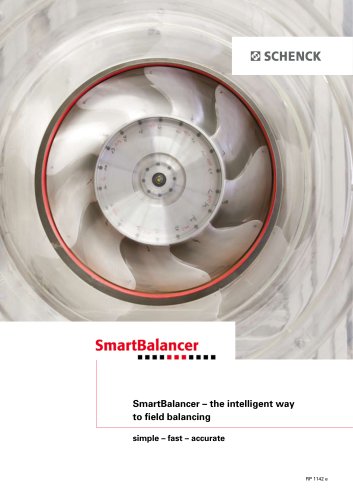

SmartBalancer

8 Pages

-

VIRIO

6 Pages