Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

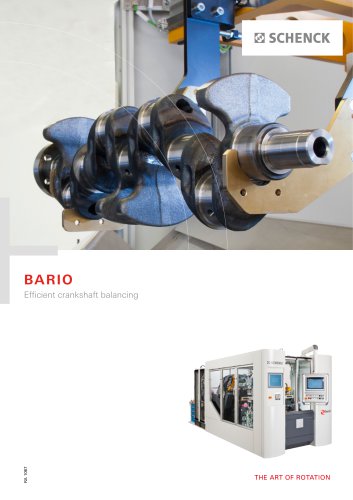

Efficient crankshaft balancing

Open the catalog to page 1

Frontrunner in the area of cost reduction Production conditions in the automotive industry are changing rapidly. Every single process step has to satisfy continuously escalating demands for efficiency, operating ergonomics and precision. In order to face up to these challenges at lowest cost, we have completely redesigned our fully automated crankshaft balancing system to produce our new BARIO machine. We have however remained true to its former high performance: as a two-station solution for measuring and drilling, the new BARIO builds seamlessly on the successes of predecessor models with...

Open the catalog to page 2

The production process is becoming more and more flexible and batch sizes are smaller. If you want to stay competitive, you can't afford to lose time during part change. The new BARIO makes it easy for you: all the machine's components are easily accessible; set-up operations are possible with the doors open, and you can change components almost without tools. In addition, changeover is facilitated through standardized change kits. Thanks to the optional tool changer, a second tool with an additional drill diameter, can be used quickly. Efficiency times five Maintenance is also designed to...

Open the catalog to page 3

The BARIO space miracle – fits into a standard 20 foot container The BARIO's chips management system is new as well: whichever way you install the system, it offers maximum freedom – the accumulating chips can be discharged to the right, the left and behind the machine. And adjustment is easy. Thanks to the concentrated chip removal, chips do not get caught and clumps do not form either. After-treatment is not necessary, because the chips are dry and not contaminated with drilling fluids. When dimensioning the new BARIO we changed the width/depth ratio so that the machine is now around 15...

Open the catalog to page 4

Well-conceived operation – efficient processes Precision that pays off Well-conceived operation down to the last detail – we committed the new BARIO to this above all. The idea of simple handling runs like a common thread through the complete operating concept. For example, to set up for a new crankshaft you need only three different types of tools. You use linear rails with marked positions to find locations again quickly and precisely, for, in example the part clamp. With a whole series of such detailed solutions the BARIO ensures efficient production process. We have increased the...

Open the catalog to page 5

State of the art measuring and controlling CAB 950 measuring and control technology 1 In the current version 6, our latest measuring and control unit “CAB 950” is designed as an intuitive and self-explanatory human-machine interface (HMI). It enables ergonomic and transparent access to all the machine's functions. Along with the precision mechanics, the CAB measuring technology is the guarantee for the greatest precision during unbalance correction. Many standard functions optimize accuracy still further, for balancing crankshafts in particular. These include statistical calibration, polar...

Open the catalog to page 6

Technical data R O T O R D I M E N S I O N S } Crankshaft weight,max.: 30 kg* } Overall length, max.: 650 mm* } Clearance crankshaft center to drive end: 100...240 mm* } Main bearing clearance, max.: (120) 170...500 mm* } Correction planes clearance, max.: 600 mm } Main bearing diameter: 40...70 mm* } Counterweight diameter, max.: 200 mm* } Correction drill diameter, max.: 20 mm (with carbide drill) M AC H I N E } Width, depth, height: 2060 mm, 5500 mm, 2200 mm } Total weight: 9000 kg } Mains connection (standard): 400 V / 3Ph / 50 Hz } Balancing speed, typical: 400...450 min -1 } Measuring...

Open the catalog to page 7All SCHENCK RoTec GmbH catalogs and technical brochures

-

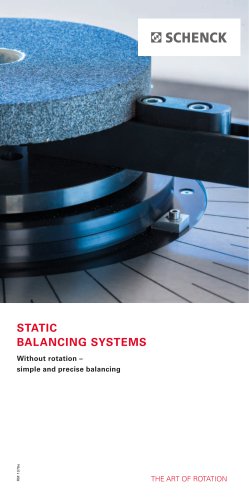

Static Balancing Systems

5 Pages

-

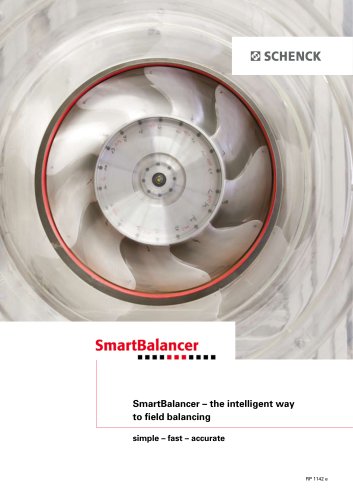

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages