Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

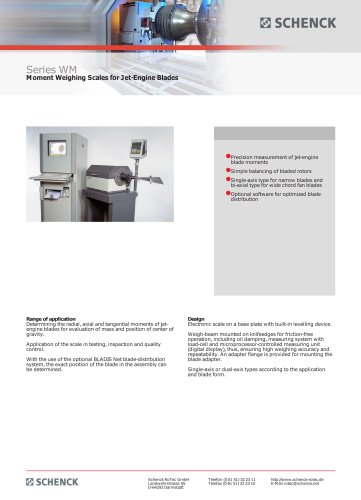

Fully automatic balancing of crankshafts Special flexibility and short changeover times Short cycle times due to high speed drilling and optimised correction Environmentally friendly operation with minimum lubrication without the necessity for drill coolant is possible High reliability due to the application of proven components Efficient measuring device CAB 850 with industrial PC and touch screen Integrated operation of measuring device and machine Balancing machines for crankshafts Type 320/520 SBRK Correction method Measuring and correction of the unbalance of completely machined crankshafts of passenger and commercial vehicles. The machine can be used for the production of medium scale series, even with a large number of different types. Loading is effected manually by means of a lifting device or automatically by means of the gantry loader. The machine is available for various size ranges. Unbalance correction by means of drilling into the counterweights in one or two correction steps. Optimised polar single spindle drilling into all counterweights permitted for such drilling, whereby any sectors can be protected or selected. In case of 2-step correction, separate areas can be selected for the 1st and the 2nd step. If different drilling diameters are required the machine can be equipped with a drilling unit including two drilling spindles and with a selection function.

Open the catalog to page 1

Load the workpiece either manually into the lifting device or by automatic operation immediately into the half shell bearing of the balancing unit. Close the protective door and start the automatic run: complete measuring run, application of correction drilling, check run, indexing in home position. • Open the protective door and unload the workpiece. Single station machine with solid balancing frame and hydrodynamic multiple bearing. Hook drive for driving the crankshafts at the crank journal. Offset drilling unit arranged at the rear with NC-controlled drilling machine. Welded machine bed...

Open the catalog to page 2

Cooling agent preparation unit with 30µ band filter and high pressure pump for operation with lubricoolant emulsions or oil and high pressure pumps for internal cooling of the drilling tool. The unbalance is measured and corrected in one station so that less operating steps are required Due to the vibrating frame with multiple half shell bearings the load per surface unit arising during drilling is reduced and less strain is put on the main bearings. The bearings are lubricated and optionally flushed. The design is made for the use of carbide tools. The sturdy construction allows for using...

Open the catalog to page 3

Data at a glance Type Measuring unit Passenger vehicle crankshafts Light commercial vehicle crankshafts Heavy commercial vehicle crankshafts Asymmetric crankshafts Journal sleeve shell and hook drive NC-controlled drilling Minimal lubrication possible Chip conveyor Total length Correction plane distance Main journal diameter Outside diameter Crank-pin diameter Balancing speed Power consumption Balancing and Diagnostic Systems Without bob weights, with manual loading max. 15 kg Acc. to DIN 1319, 95% probability, work-piece dependent, (without uncoupling and unloading) Minimum achievable...

Open the catalog to page 4All SCHENCK RoTec GmbH catalogs and technical brochures

-

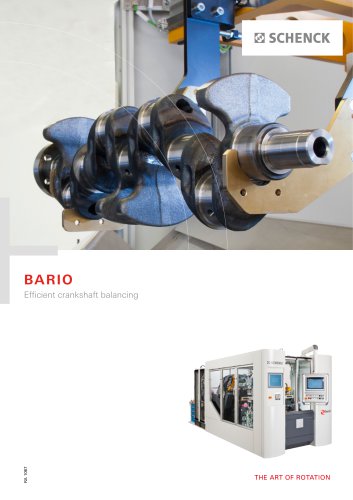

BARIO

7 Pages

-

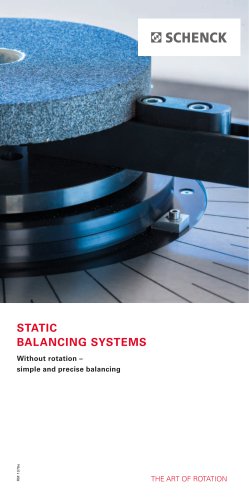

Static Balancing Systems

5 Pages

-

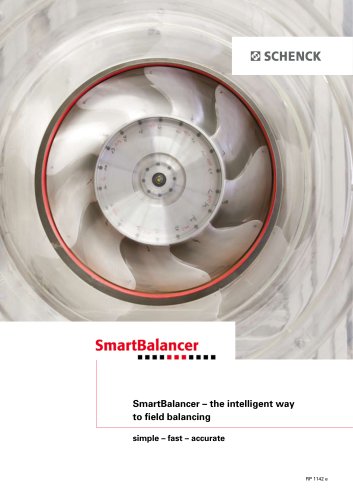

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages