Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

400 SBRZ, 600 SBRZ, 400 TBTZ, 400 MBRZ Mass-Centering Machines for Crankshafts • Modular design, change over for various crankshaft types through different carriages • Fully automatic operating sequence • Direct integration with production lines • Processing of unbalance data from the final balancing machine for optimization of the manufacturing process Range of application Mass-centering of face milled raw crankshaft castings or forgings in a variable program. Processing of symmetrical and asymmetrical crankshaft types by change over. Conceived for use by engine manufacturers in mid-volume and high-volume production. Manuel loading and unloading of the machine by lifting device or automatically by interfacing with customer's conveying equipment. Integration of preceding or subsequent process steps in the complete line. Design Mingle or multi-station machines with automatic sequence. Loading and unloading manually with a suitable lifting device, automatically by loading gantry or by integrated lift and carry transport. Flexible machine design, especially suitable for varying crankshaft programs. Manual or automatic length adjustment for change-over to various crankshaft lengths. Balancing frame supported on the machine base by round springs. Two carriage units mounted on the balancing frame with integrated externally rotating end discs mounted on precision bearings, each with two adjusting gears. Hydraulic spindle drill units or electro-mechanical carriage drill for center drilling, either integrated into the measuring station or arranged in a separate centering station. Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 1

400 SBRZ, 600 SBRZ, 400 TBTZ, 400 MBRZ Mass-Centering Machines for Crankshafts Measuring station for determining mass eccentricity by dynamic unbalance measurement. The crankshaft is loaded and unloaded from above, clamped at the main journals and driven between synchronous-rotating end discs by an amply dimensioned drive unit. Clamping and setting elements are easily exchanged for various crankshaft lengths. Adjuster gear with drive through separate stepper motors. Processing of asymmetric crankshafts by offset of the measuring unit.Single-station machines are equipped with integrated...

Open the catalog to page 2

400 SBRZ, 600 SBRZ, 400 TBTZ, 400 MBRZ Mass-Centering Machines for Crankshafts 1 Centring balancing machine2 Measuring device (operation)3 Switch cabinet4 Hydraulic assembly Plan view (non-binding example: dimensions of the switch cabinet depend on the relevant application) Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 3

Technical data at a glance Measuring unit 400 SBRZ 400 TBTZ 400 MBRZ 600 SBRZ Crankshafts for light commercial Asymmetrical crankshafts Varying type programs Automatic sequence of operations Lifting device Combined measurement and centering Separate measurement and centering Measurement only Crankshaft forging or casting Main journal diameter Balancing speed Clamping diameter Drill clamping diameter, max. Residual eccentricity Cycle time Change-over time Power consumption Swarf conveyor

Open the catalog to page 4

400 SBRZ, 600 SBRZ, 400 TBTZ, 400 MBRZ Mass-Centering Machines for Crankshafts 2) Depending on weight, unbalance and drilling time (without loading and unloading) 3) Data non-binding, depending on equipment supplied 4) According to DIN 1319, 95% probability, relative to outer counter weights, mounting on center holes Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 5All SCHENCK RoTec GmbH catalogs and technical brochures

-

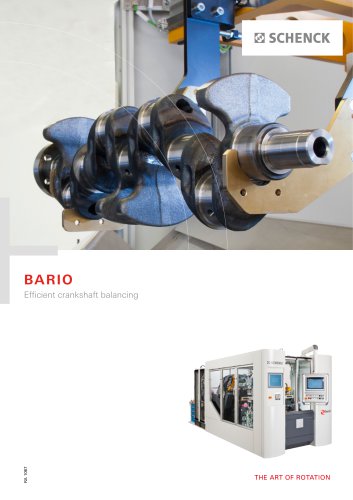

BARIO

7 Pages

-

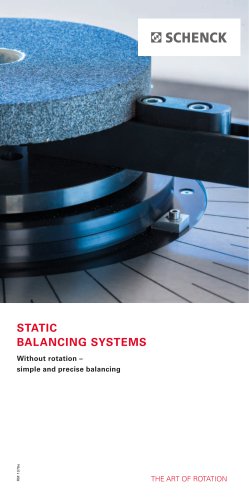

Static Balancing Systems

5 Pages

-

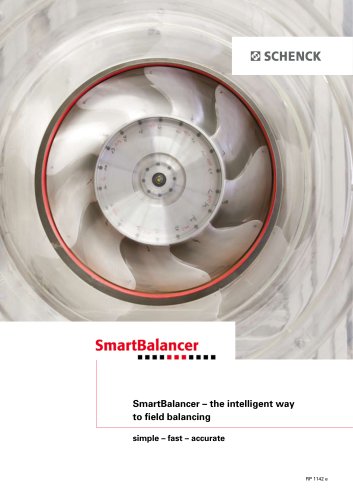

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages