Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

130 RBER, 130 SBER Assembly Machines • Gentle mounting, also with low-profile tires • Automatic sequence • Optional integration with production lines Range of application Automatic mounting of tubeless passenger-vehicle tires in normal, low-profile or super low-profile form onto steel, or aluminum rims of various dimensions. Application of the machines in mid-volume production. Linking of the machine with suitably arranged lubrication and lay-on station (130 SBER), as well as succeeding tire inflation and wheel balancing machine is possible. Loading and unloading either manually or by an optional transfer system. Design Single-station machine with fully automatic cycle, loading and unloading either manually or by transfer equipment. The welded machine housing contains the rim centering and clamping device, single-arm draw-down head with bead folder and hold-down roller, drive combination for rotation and lifting, tire-pusher and pressure pad. Automatic adjustment of the mounting head to suit the various tire widths and manual change over of the rim diameter. Fully automatic change over is optional. Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 1

130 RBER, 130 SBER Assembly Machines This assembly head provides diameter adjustment in steps. The change over to another rim diameter can be done manually by push-button or fully automatically by a type identification system. The tire mounting procedure takes only a few seconds. The heart of the system is the noncontacting draw-down head that prevents damage to the rim and especially the edge. Mounting of the two tire beads is selectively done either both at the same time, or one bead at a time in two revolutions.The machine can be changed over easily and in a short time and therefore a...

Open the catalog to page 2

Complete wheel Total width Outside diameter, tire Bead width Separate mounting of beads Cycle time Power consumption Barcode reader Wheel turner Conveying equipment 2) Data non-binding, depends on the respective equipment supplied 3) Transfer of tire and wheel data to the ine 4) Required for a deep drop base

Open the catalog to page 3All SCHENCK RoTec GmbH catalogs and technical brochures

-

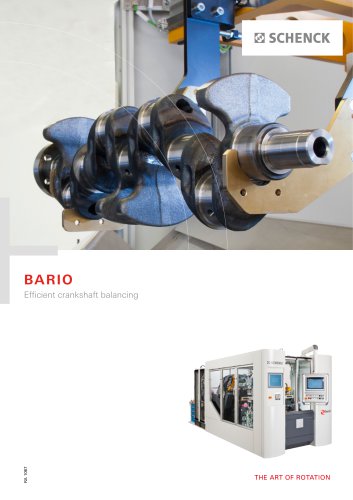

BARIO

7 Pages

-

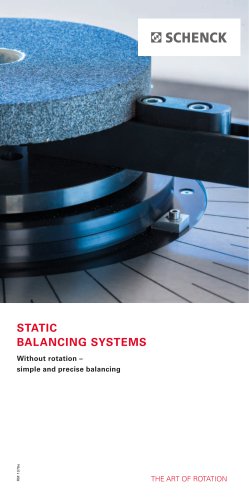

Static Balancing Systems

5 Pages

-

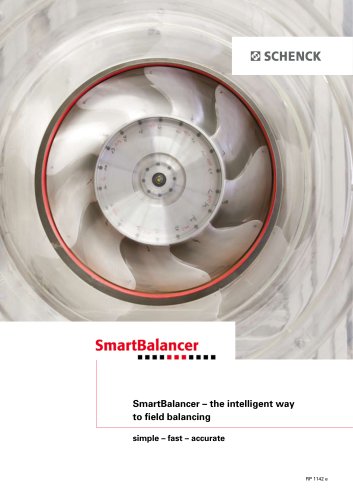

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages