Catalog excerpts

» Pneumatic Conveying » Weighing » Feeding » Milling » Screening » Extrusion » Mixing » Depositing » Cooking Integrated Bulk Material Handling Technologies for Food Pro

Open the catalog to page 1

Excellence in food technology Weighing, feeding, milling, sifting, mixing, screening, depositing, cooking, pneumatic conveying, and air filtration for the food industry from Schenck Process We have the right weighing, feeding, milling, sifting, mixing, screening, depositing, cooking, pneumatic conveying and air filtration for even your most challenging food processing applications. The combination of knowledge, field proven technology and many years of experience enables Schenck Process to offer customers within the food industry tailor-made solutions in sanitary design and for explosion...

Open the catalog to page 2

Schenck Process delivers custom-designed and engineered solutions for the following applications: » Grinding of powders and granules » Separate and de-dust dry, powdered and granular products » Starch free depositing of sugar and sugar-free confectionery Project management At Schenck Process, everything we do is centered on customer satisfaction. We strive to make your equipment and systems robust and efficient. Our project management teams become an extension of your business with a direct line of communication to the many resources within the Schenck Process global network. Your Schenck...

Open the catalog to page 3

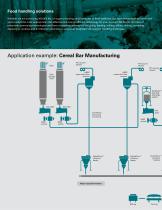

Food handling solutions Whether we are conveying 300,000 lbs. of sugar or feeding small amounts of food additives, our experienced staff will work with you to select the most appropriate, cost-effective and energy efficient technology for your product. We deliver all types of pneumatic conveying technologies and have a complete selection of weighing, feeding, milling, sifting, mixing, screening, depositing, cooking, and air filtration solutions to solve your toughest bulk material handling challenges. Application example: Cereal Bar Manufacturing PD vacuum blower PD vacuum blower PD vacuum...

Open the catalog to page 4

Schenck Process delivers custom-designed and engineered solutions for the food industry that span the following: • • • • • • Grinding of powder and granules Separate and de-dust, dry powdered and granular products Starch free depositing of sugar and sugar-free confectionery Low pressure continuous dense and dilute phase handling systems Plant controls systems Dust collection • Sifting, storage and mixer transfer systems • Ingredient unloading, cleaning and storage systems • Complete cooking from flexible small batch systems to fully automated high output lines • Ingredient dry convey...

Open the catalog to page 5

Project management At Schenck Process, everything we do is centered on customer satisfaction. We follow a customer focused eight step process that allows our experienced project managers and their teams of engineers to design the most efficient, cost effective system to meet your operational requirements on budget and on time. Understanding needs Every project begins with your operation, your conditions, your application and your unique needs. We seek to understand the issues and problems that you are facing. Application example: Sugar Truck reception AVRC filter Bulk storage silos RTC filter...

Open the catalog to page 6

Testing / research Our TestCenters allow us to develop the most innovative solution that will solve any conveying, sifting, milling, mixing, screening, air filtration, weighing or feeding challenge. In addition to our TestCenters, our database containing thousands of test records allows us to cross reference previously handled materials enabling quick identification of proven pneumatic conveying, sifting, milling, mixing, screening, air filtration, weighing and feeding solutions. Fan Dust collector system Parallel tunnel diverter valve SacMaster® big bag discharge station SacMaster® big bag...

Open the catalog to page 7

Project management Solution During this stage, we discuss the testing and research analysis with you. Using that information, a systems quote is prepared to meet your exact needs. Application example: Snack Coating Parallel tunnel diverter valve HSER pneumatic filter receiver HSER pneumatic filter receiver Extension hopper Extension hopper SolidsFlow™ vibratory feeder

Open the catalog to page 8

Design We discuss the proposal in greater detail with you in terms of initial and ongoing costs, energy consumption, delivery dates, project timetables and deadlines before agreeing and proceeding to the next step. Build/Deliver Solution No matter where you are located in the world, our global network allows us to engineer, project manage and deliver a solution. HSER pneumatic filter receiver GCA airlock Cyclone receiver Cyclone receiver Gravity diverter SolidsFlow™ vibratory feeder MechaTron® gravimetric feeder MechaTron® gravimetric feeder Sanitary pocket conveyor

Open the catalog to page 9

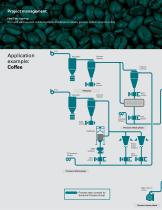

Project management First Time Start-up Our rapid start-ups with onsite engineers enable you to quickly get your system up and running. Application example: Coffee Cyclone receiver Cyclone receiver Cyclone receiver Green coffee bean cleaning equipment Pressure dilute phase SacMaster GKM screener PD pressure blower Macro surge hoppers GCA airlocks Pressure dilute phase High vacuum pump Vacuum dense phase

Open the catalog to page 10

Obtain Benefits With quick start-up you realize maximum productivity with minimal disruption at the time of implementation. Customer Support Our knowledgeable Service Center personnel are available 24/7 to assist you with ongoing support after equipment installation. Fan AVRC Pulse jet filter RAM airlock Negative air lift Cyclone receiver GCA airlock Chaff briquetter Spark cooler, detector, quencher Green coffee bean storage and scaling GCA airlock Pressure dilute phase Roasted coffee bean storage PD pressure blower HSER pneumatic filter receiver GCA airlock air controls Parallel tunnel...

Open the catalog to page 11

Feeding For accurate metering of a wide range of dry ingredients Schenck Process offers feeders for most food applications. Whether you are feeding additives into blends, cereals into extruders or coating snack foods Schenck Process has a screw, vibratory, volumetric or gravimetric feeder to meet your specific requirement. Weighfeeding When totalization, controlled flow metering or batching of fragile (friable) materials are required weighbelts are the ideal solution. An open weighdeck receives and feeds the materials without damage while accurately verifying total amounts being added to...

Open the catalog to page 12All Schenck Process Holding GmbH catalogs and technical brochures

-

Smart Dust Collection Solution

12 Pages

-

Precise feeding solutions

4 Pages

-

FulFiller ®

8 Pages

-

MULTIBELT® Belt Weigher

8 Pages

-

CONiQ® Cloud

1 Pages

-

MULTIRAIL® BogieLoad pro

20 Pages

-

Pharmaceutical industry

10 Pages

-

MULTIRAIL®

16 Pages

-

Company overview

20 Pages

-

Your way to Schenck Process

4 Pages

-

We make processes work

20 Pages

-

Material Handling Solutions

8 Pages

-

Capabilities of Stock

8 Pages

-

LinaClass® screens

6 Pages

-

Screenex® screening media

24 Pages

-

CONiQ®

12 Pages

-

Enduro isolation springs

4 Pages

-

MCPP

12 Pages

-

ModuPlasma

8 Pages

-

Airlocks and Diverter Valves

6 Pages

-

MaxiStore®

8 Pages

-

SacMaster®

8 Pages

-

Screen Rebuild Program

4 Pages

-

Food industry

20 Pages

-

MultiTrain® Technology

4 Pages

-

Training that delivers!

38 Pages

-

Cement industry

16 Pages

-

MoveMaster® chain conveyors

8 Pages

-

TEDO Conveyors

18 Pages

-

ProPulse Industrial Air Filters

12 Pages

-

Drop forged chain

8 Pages

-

RoCon® Series 6

8 Pages

-

Sustainable Cement Production

10 Pages

-

Under the harshest conditions

16 Pages

-

SPro screen panels

12 Pages

-

LOGiQ® loading automation

10 Pages

-

Power industries

16 Pages

-

Tidal Series 5

6 Pages

-

Screen rebuilding

4 Pages

-

RotoScrew

2 Pages

-

Rotofeed Pneumatic Injector

2 Pages

-

DWB

4 Pages

-

MultiFlex

4 Pages

-

Stock Forry® ESP Products

8 Pages

-

LinaClass®

6 Pages

-

Air pollution control

4 Pages

-

Stock Valves

8 Pages

-

Product Overview

8 Pages

-

MULTIDOS® H - Weighfeeder

2 Pages

-

MULTIDOS® E - Weighfeeder

4 Pages

-

SacMaster

1 Pages

-

MULTIBELT®

1 Pages

-

MULTIDOS® VDP

1 Pages

-

Components and Standard Products

206 Pages

-

DISOCONT ®

4 Pages

-

INTECONT® PLUS

4 Pages

Archived catalogs

-

We make processes work

16 Pages

-

MULTIRAIL® WheelLoad

2 Pages

-

MULTIRAIL® WheelScan

2 Pages

-

MULTIRAIL® MultiBridge

2 Pages

-

MULTIRAIL® LiquidWeight

2 Pages

-

MULTIRAIL® LegalWeight

2 Pages

-

MULTIDOS® L

4 Pages

-

MULTIGRAV®

4 Pages

-

ProFlex® C

2 Pages

-

Mobile Touch Panel FSB

2 Pages

-

DISOMAT® Satus

4 Pages

-

DISOMAT® B plus Ex, Zone 1

4 Pages

-

INTECONT® Opus

4 Pages

-

weighing sensor

1 Pages

-

Rotary Force Exciters

4 Pages

-

Force exciters

4 Pages

-

MULTISTREAM® B

4 Pages

-

MULTICOR® R 450

4 Pages

-

MULTIDOS® E

4 Pages

-

MULTIDOS® M

4 Pages

-

Award Winning Solutions

6 Pages