Catalog excerpts

Drop Forged Chain For Conveyors & Elevators Quality Components for Chain Conveyors & Elevators

Open the catalog to page 1

Introduction Members of the Schenck Process Group, Redler are leading providers of feeding, automation and bulk solids handling solutions. The Schenck Process Group are global market leaders for solutions in measuring and process technologies in industrial weighing, feeding, screening and automation. Always close to customers, with an unrivalled global network of operating companies we are your competent global partner for weighing, feeding, conveying, screening and automation solutions throughout the process industries. Our philosophy is based on... Continuous product development Best...

Open the catalog to page 2

Quality Components for Chain Conveyors & Elevators Redler, the originators of the world renowned "En-Masse" system of dry bulk materials handling continue to be at the forefront of systems development and component supply. With over 75 years of experience the Redler "En-Masse" system of handling is well proven. Redler have supplied many thousands of conveyors and elevators to handle hundreds of different dry bulk materials. At the heart of these machines is our high quality Redler Chain. High Strength Chain Links Drop forged from alloy steel Precision machined Case hardened to Rockwell 57...

Open the catalog to page 3

Pins Case hardened Alloy Steel Surface hardness Rockwell 57 minimum Effective case depth 0.6mm Connecting Pin and snug Can be used on 3122 chain requires provision of keyway to all link fixing holes chain flights & configurations Plastic Sleeve Deep ‘T’ Plate Flight

Open the catalog to page 4

Chain Configuration ❖ Links are assembled in a configuration to match individual applications. This configuration can include scavenger, cleaning or pad flights as required. £ Within a complete chain, flighted links are usually supplied at every single, second or third pitch. See sketch showing typical arrangement of a 'T' type chain. Alternative configurations available. £ Chain is usually supplied pre-assembled into 3-metre lengths complete with connecting pins. £ All assembled chains supplied with an appropriate protective coating. Special Flight Designs £ A wide range of designs are...

Open the catalog to page 5

Dimension WB1 remains the same for offset boss Flange Dimensions sprockets Chain No.of Dia PS Dia P1 Dia C Dia D N No. T X WB1 Ref. teeth mm mm mm Max mm Holes mm mm mm

Open the catalog to page 6

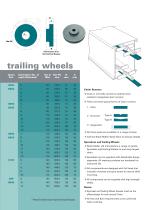

trailing wheels Chain Equivalent No. of Dia A Ref. teeth (Nominal) Max Chain Runners ^ Chain is normally carried on special wear resistant manganese steel runners. ^ There are three typical forms of chain runners. 1 - Plain *These Trailers have Symmetrical Bosses O All three types are available in a range of sizes. O Call the Stock Redler Sales Team to discuss details. Sprockets and Trailing Wheels $ Stock Redler Ltd manufacture a range of quality Sprockets and Trailing Wheels to suit drop forged chain. ^ Sprockets can be supplied with detachable flange segments. All wearing surfaces are...

Open the catalog to page 7

11.13 All information is given without obligation. All specifications are subject to change. BV-P 9011 GB Schenck Process is the global market leader of solutions in measuring and process technologies in industrial weighing, feeding, conveying, screening, automation and air filtration technology. Schenck Process develops, manufactures and markets a full range of solutions, products and turnkey systems on the basis of combining process engineering expertise, reliable components and field-proven technology. Schenck Process UK Limited Carolina Court, Lakeside Doncaster, DN4 5RA United Kingdom...

Open the catalog to page 8All Schenck Process Holding GmbH catalogs and technical brochures

-

Smart Dust Collection Solution

12 Pages

-

Precise feeding solutions

4 Pages

-

FulFiller ®

8 Pages

-

MULTIBELT® Belt Weigher

8 Pages

-

CONiQ® Cloud

1 Pages

-

MULTIRAIL® BogieLoad pro

20 Pages

-

Pharmaceutical industry

10 Pages

-

MULTIRAIL®

16 Pages

-

Company overview

20 Pages

-

Your way to Schenck Process

4 Pages

-

We make processes work

20 Pages

-

Material Handling Solutions

8 Pages

-

Capabilities of Stock

8 Pages

-

LinaClass® screens

6 Pages

-

Screenex® screening media

24 Pages

-

CONiQ®

12 Pages

-

Enduro isolation springs

4 Pages

-

MCPP

12 Pages

-

ModuPlasma

8 Pages

-

Airlocks and Diverter Valves

6 Pages

-

MaxiStore®

8 Pages

-

SacMaster®

8 Pages

-

Screen Rebuild Program

4 Pages

-

Food industry

20 Pages

-

MultiTrain® Technology

4 Pages

-

Training that delivers!

38 Pages

-

Cement industry

16 Pages

-

MoveMaster® chain conveyors

8 Pages

-

TEDO Conveyors

18 Pages

-

ProPulse Industrial Air Filters

12 Pages

-

RoCon® Series 6

8 Pages

-

Sustainable Cement Production

10 Pages

-

Under the harshest conditions

16 Pages

-

SPro screen panels

12 Pages

-

LOGiQ® loading automation

10 Pages

-

Power industries

16 Pages

-

Tidal Series 5

6 Pages

-

Screen rebuilding

4 Pages

-

RotoScrew

2 Pages

-

Rotofeed Pneumatic Injector

2 Pages

-

DWB

4 Pages

-

MultiFlex

4 Pages

-

Stock Forry® ESP Products

8 Pages

-

LinaClass®

6 Pages

-

Air pollution control

4 Pages

-

Stock Valves

8 Pages

-

Product Overview

8 Pages

-

MULTIDOS® H - Weighfeeder

2 Pages

-

MULTIDOS® E - Weighfeeder

4 Pages

-

SacMaster

1 Pages

-

MULTIBELT®

1 Pages

-

MULTIDOS® VDP

1 Pages

-

Components and Standard Products

206 Pages

-

DISOCONT ®

4 Pages

-

INTECONT® PLUS

4 Pages

Archived catalogs

-

We make processes work

16 Pages

-

MULTIRAIL® WheelLoad

2 Pages

-

MULTIRAIL® WheelScan

2 Pages

-

MULTIRAIL® MultiBridge

2 Pages

-

MULTIRAIL® LiquidWeight

2 Pages

-

MULTIRAIL® LegalWeight

2 Pages

-

MULTIDOS® L

4 Pages

-

MULTIGRAV®

4 Pages

-

ProFlex® C

2 Pages

-

Mobile Touch Panel FSB

2 Pages

-

DISOMAT® Satus

4 Pages

-

DISOMAT® B plus Ex, Zone 1

4 Pages

-

INTECONT® Opus

4 Pages

-

weighing sensor

1 Pages

-

Rotary Force Exciters

4 Pages

-

Force exciters

4 Pages

-

MULTISTREAM® B

4 Pages

-

MULTICOR® R 450

4 Pages

-

MULTIDOS® E

4 Pages

-

MULTIDOS® M

4 Pages

-

Award Winning Solutions

6 Pages