Catalog excerpts

smart welding Designed for robot-assisted welding applications, this 3D-scan system is capable of swiftly positioning the laser beam along 3D contours. While a robot guides the scan system along a part's contour, the intellil/1/H.D® quickly and accurately moves and fine- positions the laser spot. Complex robotic motions and fast robotic repositioning are thereby avoided, thus reducing positioning times between spot welds to a few milliseconds. The result is a substan- tially enhanced utilization of the laser source. Despite its 30 mm aperture, the intellil/1/EZ.D® occupies a remark- ably small volume, making it easily mountable on welding robots, even in difficult-to-access locations. Its optics are optimized for fiber-coupled disk or fiber lasers with powers up to 8 kW. The intellil/1/fl.D® is based on SCANLAB's fully digital iDRIVE® technology, offering an integrated approach to laser and process safety. The technology allows real-time monitoring of all important scan head status parameters. A software-independent interlock signal indicates abnormal operational states. Typical applications: • Robot-assisted welding ("remote welding")

Open the catalog to page 1

2 Flange (robot adapter plate) * 4 Attachment provision for strain relief (fiber) 5 Attachment provision for fiber adapter 6 Connector for cooling water 10 Bore holes for attaching an objective holder and a crossjet The laser beam is fiber-delivered to the scan system's water-cooled collimator and then directed to the scan system's moving deflection mirrors. With pre-objective scanning design, focusing of the beam onto the working plane is achieved via a scan objective at the system's beam exit. With post-objective scanning design, focu- sing is achieved via an integrated focusing optic in...

Open the catalog to page 2

SCANLAB's fully digital \DRIVE® technol- ogy, offering an integrated approach to laser and process safety. It allows real-time monitoring of all important scan head and double protective window status parame- ters. This facilitates detection of process miss-queues and enables advanced remote- diagnostics. A software-independent inter- lock signal, indicating abnormal operational states, can be used to switch the system to a predefined state or trigger an auto- matic emergency stop. • A Teach-in Module simplifies the set- up of laser scan systems for welding jobs. It is permanently installed...

Open the catalog to page 3

Specifications (all angles are in optical degrees) Maximum laser power (with specified cooling) Limiting numerical aperture typ. 0.125 (3) (other types on request) Step response time (with "step" tuning) (settling to 1/1000 of full scale) Typical speeds (with Processing Speed Positioning Speed vector" tuning) Dynamic performance Tracking error Long-term drift over 8 h (after warm-up) Optical performance Typical scan angle Gain error Power requirements Input and output signals SL2-100or optical data transfer Typical water 2)the maximum laser power may be reduced with broadband scan mirrors...

Open the catalog to page 4All SCANLAB GmbH catalogs and technical brochures

-

smart scanning

6 Pages

-

intelliSCAN IV

4 Pages

-

excelliSHIFT

1 Pages

-

dynAXIS 421

4 Pages

-

powerSCAN II 50i

2 Pages

-

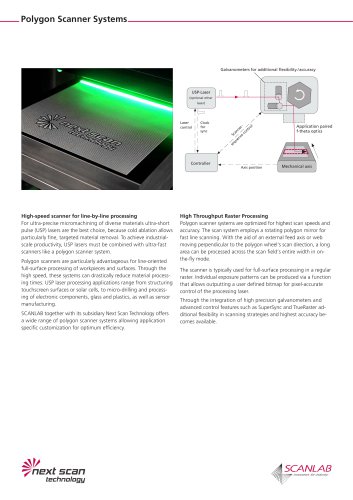

Polygon Scanner Systems

2 Pages

-

palmSCAN

2 Pages

-

laserDESK

4 Pages

-

intelliWELD II, intelliWELD

4 Pages

-

basiCube

2 Pages

-

basiCube14

2 Pages

-

rtc4

2 Pages

-

powerscanpowerscani

4 Pages

-

intelliscaniii

2 Pages

-

intelliscanse

2 Pages

-

intelliSCAN+intelliScande

4 Pages

-

hurryscaniiihurryscan

4 Pages

-

high-speed z axis

1 Pages

-

dynaxis

2 Pages

-

CollimationModul

2 Pages

-

excelliSCAN scan system

4 Pages

-

Company Profile SCANLAB AG

24 Pages

-

SCANalign Vision System

4 Pages

-

basiCube 10 scan head

2 Pages

-

hand-held scan-device

2 Pages

-

universal and compatible

4 Pages

-

intelliSCAN III Scan Heads

2 Pages

-

Galvanometer Scanners

2 Pages

-

Scancube III Scan Heads

2 Pages

-

Camera Adapter

2 Pages

-

laserDESK Software

4 Pages

-

RTC5 control boards

2 Pages

-

Automatic Self Calibration

1 Pages

-

Scan System "powerSCAN"

4 Pages

-

2D Scan Heads "hurrySCAN"

4 Pages

Archived catalogs

-

Camera Adapter

2 Pages

-

RTC®5

2 Pages

-

RTC®3, RTC®4

2 Pages

-

powerSCAN 33

2 Pages

-

intelliWELD® 30 FC

2 Pages

-

intelliSCAN®

2 Pages

-

SCANcube® 7, 8.5, 10, 14

2 Pages