Catalog excerpts

the new premium scanning standard SCANLAB's excelliSCAN scan head sets new high-end standards for meeting the most challenging demands. Its groundbreaking SCANahead control technology and field-proven dynAXISse digitalencoder galvanometers attain previously unreachable dynamic performance and precision. This translates to enormous gains in productivity and process accuracy. Innovative excelliSCAN design features: New SCANahead control • Full utilization of scanner dynamics for higher throughput • No unwanted necking effects when rapidly processing circles • Universal tuning optimized for all applications dynAXISse digital-encoder galvanometers • Maximum linearity and minimum position noise ensure highest positioning accuracy • High long-term stability even with ambient temperature fluctuations and 24/7-operation Housing innovations • Enhanced thermal management for higher load resilience • Variant with active air cooling available for applications that don't allow water as a coolant • Increased tightness (IP56) and robustness SCANLAB offers excelliSCAN in combination with the RTC6 PCIExpress control board. With its substantially increased processing power and optimum support of SCANahead control technology, the RTC6 opens up new system-control p

Open the catalog to page 1

excelliSCAN SCANahead control SCANahead principle of operation Conventional control SCANahead control allows excelliSCAN to deliver full acceleration even at slow scan speeds (i.e. with minimum acceleration duration ta). Pre-computed set-point trajectories make this possible. Computation occurs in real time, offset by the look-ahead time tp, prior to actual execution. Limiting trajectory acceleration to the scanner axes' full acceleration produces a set-point trajectory (blue curve) that the SCANahead control can track without tracking error (red curve). Thus, the galvos' dynamic...

Open the catalog to page 2

• Concept fundamentally eliminates it. Processing circles, arcs Tracking error Conventional control • Acceleration time is constant at all scan speeds: acceleration potential isn't fully utilized. • Necking effects (caused by tracking error) need to be offset by adjusting circle diameters. • Finite, constant value • Precise image field correction even at high speeds SCANahead control • Scanner axis acceleration always at maximum: acceleration time is minimized. • Necking effects avoided. • Limits precision of image field correction at high speeds • Only one tuning needed. Optimum...

Open the catalog to page 3

excelliSCAN + RTC 6 Preliminary specifications excelliSCAN 14 Aperture Tuning Tracking error Acceleration Repeatability (RMS) Positioning resolution Optical performance Typical scan angle Gain error Zero offset Nonlinearity Power requirements Interface Operating temperature Weight Typical speeds (1) Positioning, jump & shoot Line scan / raster scan Typical vector marking Good writing quality High writing quality Positioning times 1 mm jump width 10 mm jump width 100 mm jump width ±0.35 rad < 5 mrad < 5 mrad < 0.5 mrad / 44° 30 V DC, max. 3 A SL2-100 25 °C ± 10 °C approx. 7 kg with F-Theta...

Open the catalog to page 4All SCANLAB GmbH catalogs and technical brochures

-

smart scanning

6 Pages

-

intelliSCAN IV

4 Pages

-

excelliSHIFT

1 Pages

-

dynAXIS 421

4 Pages

-

powerSCAN II 50i

2 Pages

-

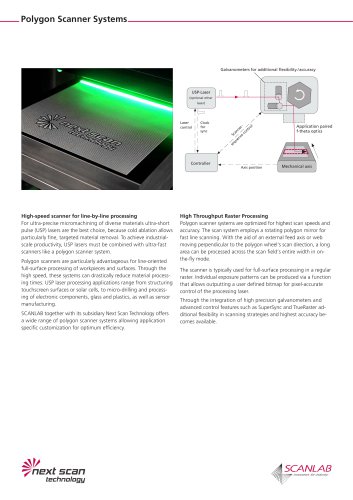

Polygon Scanner Systems

2 Pages

-

palmSCAN

2 Pages

-

laserDESK

4 Pages

-

intelliWELD II, intelliWELD

4 Pages

-

basiCube

2 Pages

-

basiCube14

2 Pages

-

rtc4

2 Pages

-

powerscanpowerscani

4 Pages

-

intelliscaniii

2 Pages

-

intelliscanse

2 Pages

-

intelliSCAN+intelliScande

4 Pages

-

hurryscaniiihurryscan

4 Pages

-

high-speed z axis

1 Pages

-

dynaxis

2 Pages

-

CollimationModul

2 Pages

-

Company Profile SCANLAB AG

24 Pages

-

SCANalign Vision System

4 Pages

-

basiCube 10 scan head

2 Pages

-

hand-held scan-device

2 Pages

-

universal and compatible

4 Pages

-

intelliSCAN III Scan Heads

2 Pages

-

Galvanometer Scanners

2 Pages

-

Scancube III Scan Heads

2 Pages

-

Camera Adapter

2 Pages

-

laserDESK Software

4 Pages

-

RTC5 control boards

2 Pages

-

Automatic Self Calibration

1 Pages

-

Scan System "powerSCAN"

4 Pages

-

Scan-System "intelliWELD"

4 Pages

-

2D Scan Heads "hurrySCAN"

4 Pages

Archived catalogs

-

Camera Adapter

2 Pages

-

RTC®5

2 Pages

-

RTC®3, RTC®4

2 Pages

-

powerSCAN 33

2 Pages

-

intelliWELD® 30 FC

2 Pages

-

intelliSCAN®

2 Pages

-

SCANcube® 7, 8.5, 10, 14

2 Pages