Website:

SANTSAI MACHINERY

Website:

SANTSAI MACHINERY

Group: SANTSAI

Catalog excerpts

/ ACHIEVEMENT VALUE BY HEART UNIVERSE Series The 3rd Generation High-efficiency Precision Injection Molding Machine

Open the catalog to page 1

/ ACHIEVEMENT VALUE BY HEART UNIVERSE Series The 3rd Generation High-efficiency Precision Injection Molding Machine

Open the catalog to page 2

Founded in 1955, ZHEJIANG SOUND MACHINERY MANUFACTURE CO., LTD is one of the earliest professional manufacturers of injection molding machine in China, which is affiliated to ZHEJIANG ARTIKING GROUP CO., LTD . SOUND is the pioneer of China’s plastic machinery industry, the first batch of national high-tech enterprises in the industry, the key enterprise of "a Group of Five" in Zhejiang province. SOUND has won the only National Silver Award in domestic plastic machinery industry, the second prize of National Science and Technology Progress Award, the frist prize of Zhejiang Science and...

Open the catalog to page 3

Provide you with a one-stop injection molding solution with high adaptability and cost-effectiveness! Since in 1955, SOUND has been committed to creating the highest value for customers with high-quality, high-efficient and high-precise products for more than 60 years. The Universe 3rd generation high-efficiency precision injection molding machine inherits the excellent genes of SOUND and was carefully built by the Japanese team. With large parameters, high adaptability and high cost-effectiveness, Universe series machine has become your reliable product to meet your production requirements...

Open the catalog to page 4

SOUND MACHINERY High Quality High Precision Large parameters for all known injection molding processes, wide application range. According to the Japanese modularization, life management design and meticulous production, high quality, high cost-effective, personalized configuration. Dual crank arm clamping structure, solid, stable, reliable and durable, suitable for 24-hour uninterrupted work. Repeatability accuracy of mold opening and closing position ±0.5mm Repeatability accuracy of shot weight 0.7% - 0.3% High Efficient Energy Saving High Efficient servo driver technology ensures high...

Open the catalog to page 5

Clamping Unit k\ Large Toggle Stroke ^ Large Parameter High Adaptability (under the same clamping force condition) For the machine with same tonnage, toggle stroke is larger than other competitors, which is convenient for installing bigger mold. Large Space Between Tie Bars: Suitable for big and small molds, and the molds are widely applicable.

Open the catalog to page 6

Clamping Unit PAGE 07/08 High QualityHigh Quality, Stable and Reliable Clamping Unit The large drawing lines of the clamping part are marked with the following selling points: * Dual crank arm clamping structure, it is solid, stable, reliable and durable, suitable for 24-hour uninterrupted work. • The whole series configure T-slot & threaded hole mold platen as standard, which makes mold replacement faster and more convenient, effectively solving the problem of easy damage to the thread of the threaded hole platen • The centrally reinforced moving platen and front platen design, can...

Open the catalog to page 7

PAGE 09/10 • The whole machine adopts high performance hose and DIN standard hydraulic joint, no welding, no oil leakage, no pollution. • Multi-pump combination technology, electric servo injection technology and hydraulic accumulator technology realize the independent action of each motion axis, making high efficient production so simple. • Through the hydraulic expansion combination to achieve a short cycle. Strong selectivity and high cost performance to meet the requirements of different customers. • High Efficient servo system + internal gear pump, output energy consumption varies with...

Open the catalog to page 8

Precise and High Adaptability Injection Unit • The Universe series injection unit adopts a double-layer injection structure, and the in action cylinder with double-outstretched rod structure of high-speed machine structure, • which greatly improves the injection accuracy and charging stability. • The whole series adopt high rigid injection base and high precision linear slide rail, making injection response more rapid, accurate and stable. • The movement of injection unit adopts high-rigidity guide column structure + double injection movement structure to avoid material leakage during...

Open the catalog to page 9

• The whole series machines configure large-screen controller as standard, friendly Ul interface, and better conveying information. • Standard SPC quality control and management system to help achieve continuous stability and redicatability of the process, improve production capacity, product quality and reduce costs. • SVP servo pump, accurately control response speed, convenient system maintenance, energy saving. • Powerful software control function makes the complicated injection molding process simple and easy to operate. • The main electrical components are all imported brands such as...

Open the catalog to page 10

Mold Platen Drawing UN100-EPIII

Open the catalog to page 11

Mold Platen Drawing INJECTION UNIT screw specification Shot volume Shot weight(PS) Injection pressure Injection rate Plasticizing capacity Max.screw speed CLAMPING UNIT Clamping force Space between tie bars(HxV) MIN.mold dimension(HxV) Toggle stroke Min.mold height Max.mold height Distance between platens(daylight) Ejector stroke Ejector force Number of ejector POWER UNIT Systerm pressure Pump motor Heating capacity

Open the catalog to page 12

Mold Platen Drawing screw specification Shot weight(PS) Injection pressure Injection rate Plasticizing capacity Max.screw speed CLAMPING UNIT Space between tie bars(HxV) mm 870X820 920X870 1000X920 1120X1020 1220X1120 POWER UNIT

Open the catalog to page 13

PAGE 21/22 Feature Description Feature Description Bl-metal Screw: B, C, D screw + nitriding barrel • • Chrome plated screw: A screw + nitriding barrel • • Full hard screw + BI-metal barrel O O High wear resistance and corrosion resistant screw, barrel O O Needle shur-off nozzle O O Hydraulic/air shut-off nozzle O O Balanced dual cylinder injection unit • • Balanced dual cylinder carriage unit • • High rigid double layer injection system • • Injection unit increase&decrease O O Hydraulic motor increase O O Injection transducer • • Screw speed display • • Feeding mould temp. auto controlled...

Open the catalog to page 14All SANTSAI MACHINERY catalogs and technical brochures

-

Rubber IMM Catalogue 2022

16 Pages

-

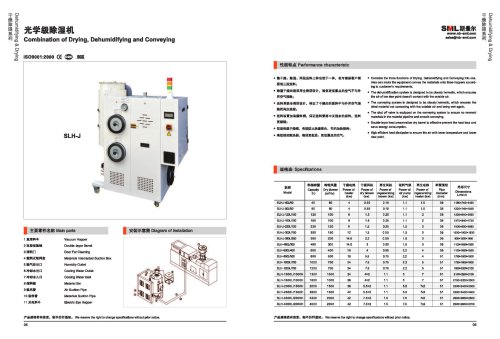

Dryer-SANTSAI MACHINERY

1 Pages

-

Central Conveying System 2020

16 Pages

Archived catalogs

-

Paper Roll Hand pallet truck

2 Pages