Catalog excerpts

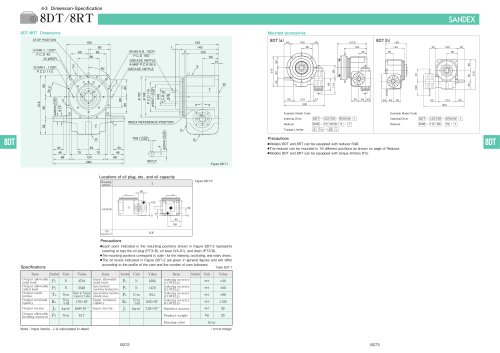

STOP POSITION GREASE NIPPLE GREASE NIPPLE INDEX REFERENCE POSITION, Locations of oil plug, ets., and oil capacity •Each point indicated in the mounting positions shown in Figure 8DT-2 represents (starting at top) the oil plug (PT3/8), oil level (VA-01), and drain (PT3/8). •The mounting positions correspond to code i for the indexing, oscillating, and rotary drives. •The oil levels indicated in Figure 8DT-2 are given in general figures and will differ according to the profile of the cam and the number of cam followers. Note : Input inertia : J is calculated in dwell Mounted accessories Example Model Code Example Model Code •Models 8DT and 8RT can be equipped with reducer R48. •The reducer can be mounted in 16 different positions as shown on page of Reducer. •Models 8DT and 8RT can be equipped with torque limiters 8T0.

Open the catalog to page 1

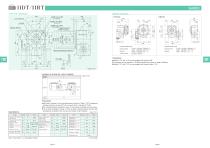

STOP POSITION GREASE NIPPLE GREASE NIPPLE INDEX REFERENCE POSITION/ Locations of oil plug, ets., and oil capacity •Each point indicated in the mounting positions shown in Figure 11 DT-2 represents (starting at top) the oil plug (PT3/8), oil level (VA-01), and drain (PT3/8). •The mounting positions correspond to code i for the indexing, oscillating, and rotary drives. •The oil levels indicated in Figure 11 DT-2 are given in general figures and will differ according to the profile of the cam and the number of cam followers. Note : Input inertia : J is calculated in dwell Mounted accessories...

Open the catalog to page 2

INDEX REFERENCE POSITION

Open the catalog to page 3

STOP POSITION GREASE NIPPLE Locations of oil plug, ets., and oil capacity •Each point indicated in the mounting positions shown in Figure 18DT-2 represents (starting at top) the oil plug (PT1/2), oil level (VA), and drain (PT1/2). •The mounting positions correspond to code i for the indexing, oscillating, and rotary drives. •The oil levels indicated in Figure 18DT-2 are given in general figures and will differ according to the profile of the cam and the number of cam followers. Note : Input inertia : J is calculated in dwell Mounted accessories Example Model Code Torque Limiter Example...

Open the catalog to page 4

Locations of oil plug, ets., and oil capacity Note : Input inertia : J is calculated in dwell Mounted accessories Example Model Code Example Model Code Example Model Code Torque Limiter Example Model Code •Models 25DT and 25RT can be equipped with reducers R100 and R125. •The reducer can be mounted in 16 different positions as shown on page of Reducer. •Models 25DT and 25RT can be equipped with torque limiters 25To.

Open the catalog to page 5

Locations of oil plug, ets., and oil capacity Note : Input inertia : J is calculated in dwell Mounted accessories Example Model Code Example Model Code Example Model Code Example Model Code Indexing Drive •Models 35DT and 35RT can be equipped with reducers R125 and R160 •The reducer can be mounted in 16 different positions as shown on page of Reducer,

Open the catalog to page 6

STOP POSITION GREASE NIPPLE Locations of oil plug, ets., and oil capacity Example Model Code Example Model Code Example Model Code Example Model Code •Models 45DT and 45RT can be equipped with reducer R160. •The reducer can be mounted in 16 different positions as shown on page of Reducer.

Open the catalog to page 7

Locations of oil plug, ets., and oil capacity •Each point indicated in the mounting positions shown in Figure 45DTR-2 represents (starting at top) the oil plug (PT1), oil level (VB), and drain (PT1) •The mounting positions correspond to code i for the indexing, oscillating, and rotary drives, •The oil levels indicated in Figure 45DTR-2 are given in general figures and will differ according to the profile of the cam and the number of cam followers. Note : Input inertia : J is calculated in dwell

Open the catalog to page 8

Locations of oil plug, ets., and oil capacity •Each point indicated in the mounting positions shown in Figure 55DTR-2 represents (starting at top) the oil plug (PT2), oil level (VC), and drain (PT1) •The mounting positions correspond to code i for the indexing, oscillating, and rotary drives, •The oil levels indicated in Figure 55DTR-2 are given in general figures and wil differ according to the profile of the cam and the number of cam followers. Note : Input inertia : J is calculated in dwell

Open the catalog to page 9

Locations of oil plug, ets., and oil capacity •Each point indicated in the mounting positions shown in Figure 65DTR-2 represents (starting at top) the oil plug (PT2), oil level (VC), and drain (PT1) •The mounting positions correspond to code i for the indexing, oscillating, and rotary drives, •The oil levels indicated in Figure 65DTR-2 are given in general figures and will differ according to the profile of the cam and the number of cam followers. Note : Input inertia : J is calculated in dwell

Open the catalog to page 10

STOP POSITION Note : Input inertia : J is calculated in dwell

Open the catalog to page 11All SANKYO catalogs and technical brochures

-

RCC Series

8 Pages

-

RW series

8 Pages

-

SPC Series

2 Pages

-

TCU Series

2 Pages

-

RSD Series

1 Pages

-

EX Series

1 Pages

-

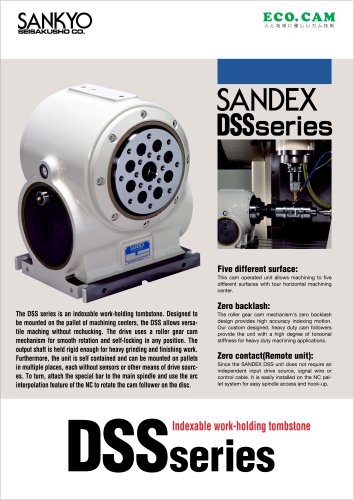

DSS Series

1 Pages

-

DST Series

1 Pages

-

VS-s Series

2 Pages

-

CNC Series

16 Pages

-

ECO Series

32 Pages

-

α (Alpha) Series

44 Pages

-

Large RU Series

24 Pages

-

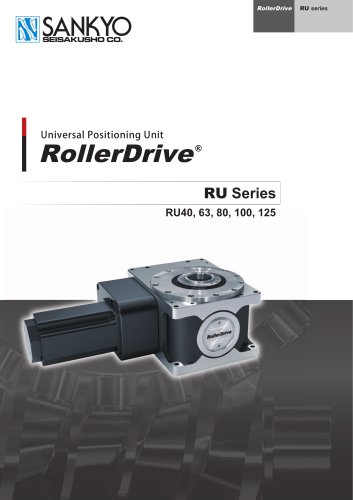

RU Series

28 Pages

-

RE series

20 Pages

-

Precision adjustable feed Variax

12 Pages

-

SANDEX

8 Pages

-

RollerDrive

28 Pages

-

Do series

7 Pages

-

RY series

16 Pages

-

RA series

32 Pages