Website:

Sankyo Oilless Industry

Website:

Sankyo Oilless Industry

Catalog excerpts

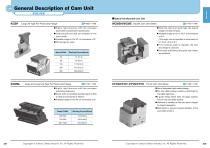

•Compact design with the mounting width of 52 mm and the shut height of 125 mm. • Automatic alignment mechanism of the V-shaped guide. •Available angle is 0°to 80° at increments of 5°. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved.

Open the catalog to page 1

General Description of Cam Unit OVER VIEW Cam Units HUCTF For thick metal pierce reinforced return force type ^P.683~716 UCMSC80-150 Standard Type for Pierce ^P.787~850 •Strong type with spring force of about 6000 N-600 kgf. It is most suitable for piercing of high strength steel and thick steel. • Automatic alignment mechanism of the V-shaped guide. •Available angle is 0° to 75° at increments of 5°. • ISO springs are used. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. 542

Open the catalog to page 2

General Description of Cam Unit OVER VIEW Cam Units SOUK Standard Type for Pierce and Flange ^P.851~944 SUWB Wide Type For Pierce and Flange ^P.1007~1098 • Highly rigid sliding structure of cam slider. •Cam Slider is removable from the back side. •Available angle is 0° to 70° at increments of 5°. • 65,100 and 200 are available for the mount width. • 200, 300, 400, 500 and 600 are available for the mount width. • Automatic alignment mechanism of the V-shaped guide. •Cam Slider is removable from the back side. •Available angle is 0° to 60° at increments of 10°. Copyright © Sankyo Oilless...

Open the catalog to page 3

General Description of Cam Unit OVER VIEW I Types and Features of Die Mounted Cam Unit Cam Units UCMSL Large and Long Life Type For Pierce and Flange ^P. 1267—1352 CMSD Compact Type For Pierce ^P. 1555—1574 •500 to 1000 at the increments of 100 mm are available for the mount width. •Available angle is 0° to 60° at increments of 10°. • 52 and 90 are available for the mount width. • Easy to remove the cam slider. •Available angle is 0° to 20° at increments of 5°. (Up to 15°for CMSD90) Mount Width Mount Width UCMSNR NAAMS standards for pierce and flange ^P.1353—1486 SKC/SKCA Standard...

Open the catalog to page 4

General Description of Cam Unit OVER VIEW ISpecial Die Mounted Cam Unit Cam Units KGSP Long Life Type For Pierce and Flange WCMSH/WCMS Double Cam Unit Series • Highly rigid structure with the overseas automobile manufacturer specification. •52,80,150,200 and 300 are available for the mount width. •Available angle is 0°to 30° at increments of 5°. • ISO springs are used. CTCS/CTCH2CTVS/CTVH Thrust Cam Unit Series ^P.1789—1798 Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. • Use of integrated rigid casting design...

Open the catalog to page 5

General Description of Cam Unit OVER VIEW Available for large cam or dedicated cam to customer's specification. List of cam unit option ^■Code SC Cat.No SC In addition to standard cam units, customized cam units may be manufactured. Large cams or dedicated cams are products that can satisfy requirements of customers for module units on dies. Reduction of lead time, indirect costs, etc. contributes to die manufacturing of customers. Large Cam Cams which have conventionally been manufactured together with dies are separated into units. Dies are simplified and cam units are customized to...

Open the catalog to page 6

General Description of Cam Unit( AERIAL CAM UNIT OPTION ~") Option ■Tapped Hole and Dowel Pin Hole (Prepared Hole, Finish) Machining for Retainer Mounting • Instruction method for machining • Indicate the tapped hole diameter and the dowel pin hole (or prepared hole) diameter with the XY coordinates. •To indicate the coordinates •The origin is positioned at the upper l eft corner of the mo unt surface. • Indication symbol M...Tapped hole,K...Dowel pin prepared hole,N...Dowel pin finish hole • Machining standard •Tapped holes and dowel pin prepared holes are machined to general...

Open the catalog to page 7

OVER VIEW Calculation Formula of Force Applied to Aerial Cam Unit θ : Working angle 1 2 θ : Cam Angle F : Force Required for Working (Working Force + Spring Return Force + Pad Force) P : Press force V : Load Applied to Cam Driver Surface Q : Load Applied to Cam Slider Surface S : Travel S' : Spring Travel L : Press Travel Locating and Installation Procedure of Pierce Punch (retainer) in Aerial Cam Unit General Description of Cam Unit Drill the mounting holes and dowel pin holes (finish) on the die for the cam holder and the driver. Fix the cam holder and the driver on the die with bolts and...

Open the catalog to page 8

General Description of Cam Unit OVER VIEW ■Calculation Formula of Force Applied to Die Mounted Cam Unit Cam Units 0 : Working Angle 0i : Driver Inclination Angle F : Force Required for Working (Working force + Spring Return Force + Pad Force) P : Press Force V : Load Applied to Cam Driver Surface Q : Load applied to Cam Slider Ssurface S : Working Travel L : Press Travel Cam Diagram •No Inclination of Working Angle (0") Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. 556

Open the catalog to page 9

General Description of Cam Unit Guide Line for Selection (Aerial Cam) OVER VIEW (Mount width) 1000 900 800 700 600 500 400 300 200 165 150 100 80 70 65 52 50

Open the catalog to page 10

Guide Line for Selection (Die Mounted Cam) General Description of Cam Unit< OVER VIEW - (Working Force tonf) Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. 560

Open the catalog to page 11

General Description of Cam UnitAERIAL CAM UNIT SELECTION TABLE ") Cam Units 561 Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. 562

Open the catalog to page 12

General Description of Cam UnitAERIAL CAM UNIT SELECTION TABLE ") Catalog No. 563 Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. 564

Open the catalog to page 13All Sankyo Oilless Industry catalogs and technical brochures

-

UCNBK100

16 Pages

-

UCNBK200

16 Pages

-

UCNBK65

16 Pages

-

SOUK200

16 Pages

-

SOUK100

16 Pages

-

SOUK65

16 Pages

-

UCMSC F150

17 Pages

-

UCMSC150

17 Pages

-

UCMSC

17 Pages

-

UCMSC80

17 Pages

-

UCMSC65

16 Pages

-

UCMSC50

16 Pages

-

HUCTF

17 Pages

-

SULNC

8 Pages

-

SACE

14 Pages

-

SUCD

18 Pages

-

SACLB80

2 Pages

-

blanking die system

4 Pages

-

SESF

1 Pages

-

SACD

14 Pages

-

SLSD

12 Pages

-

SESW / SESWT

1 Pages

-

TSP

1 Pages

-

Stroke End Block

1 Pages

-

Spring Plunger

1 Pages

-

Feed Sensor

1 Pages

-

Locating Cone

1 Pages

-

Bush Flange type:SOBF

2 Pages

-

Rubber Spring:SRX,SRXT

6 Pages

-

HLSGC

1 Pages

-

CBSL, CBSPL

1 Pages

-

Guide pin

1 Pages

-

SOB

4 Pages

-

SBLT

1 Pages