Catalog excerpts

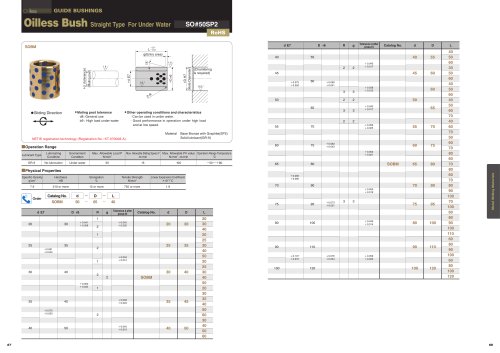

GUIDE BUSHINGS Blank Material for Oilless Bushing Growing Cast Iron/Copper Alloy Casting qFriction characteristics (SO#30:Growing Cast Iron) (SO#60:Copper Alloy Casting) t Pipe 25 Drive Condition Y No lubrication,Intermittent rotation Y Speed Vm5m/min qS30 (SO#30 : Growing Cast Iron Type) RoHS L qS30 (SO#30 : Growing Cast Iron Type) It has excellent wear resistance and seizure resistance of casting, and it is the oil impregnated bearing that has internal porosity by repeated composition adjustment and heat treatment in the porosity. · Less noise owing to porous structure. · High dimensional stability due to uniform material quality. · Where reduction in oil lubrication is desired. · Where reduction in vibration and sliding noise is desired. qS60 (SO#60 : Copper Alloy Casting Type) The major composition is copper alloy. With addition of special elements such as tin, zinc, etc., generation of crystal in solidification of molten metal is controlled. This easily generates minute shrink holes or discharge holes of melting gas. The base metal of the bearing has minute porosity and it is impregnated with high grade lubrication oil. · Piston ring, piston guide of hydraulic unit · Cylinder sleeve. · Bush for blower. Max. Allowable Sliding Speed V Max. Allowable PV value Operation Range Temperature 2 ˚C m/min N/mm Ym/min Lubricating Condition Environment Condition Regular lubrication Regular lubrication qPhysical Properties Tensile Strength 2 N/mm Linear Expansion Coefficient ×10−5/˚C Impregnation ratio % Modules of longitudinal elasticity 2 kN/mm qS60 (SO#60 : Copper Alloy Casting Type) qOperation Range · Less lubrication frequencies than before. Pipe Type Metal Sliding Materials

Open the catalog to page 1All Sankyo Oilless Industry catalogs and technical brochures

-

UCNBK100

16 Pages

-

UCNBK200

16 Pages

-

UCNBK65

16 Pages

-

SOUK200

16 Pages

-

SOUK100

16 Pages

-

SOUK65

16 Pages

-

UCMSC F150

17 Pages

-

UCMSC150

17 Pages

-

UCMSC

17 Pages

-

UCMSC80

17 Pages

-

UCMSC65

16 Pages

-

UCMSC50

16 Pages

-

HUCTF

17 Pages

-

SULNC

8 Pages

-

SACE

14 Pages

-

SUCD

18 Pages

-

SACLB80

2 Pages

-

blanking die system

4 Pages

-

General Description of Cam Unit

20 Pages

-

SESF

1 Pages

-

SACD

14 Pages

-

SLSD

12 Pages

-

SESW / SESWT

1 Pages

-

TSP

1 Pages

-

Stroke End Block

1 Pages

-

Spring Plunger

1 Pages

-

Feed Sensor

1 Pages

-

Locating Cone

1 Pages

-

Bush Flange type:SOBF

2 Pages

-

Rubber Spring:SRX,SRXT

6 Pages

-

HLSGC

1 Pages

-

CBSL, CBSPL

1 Pages

-

Guide pin

1 Pages

-

SOB

4 Pages

-

SBLT

1 Pages