Website:

SANKYO OILLESS INDUSTRY,INC.

Website:

SANKYO OILLESS INDUSTRY,INC.

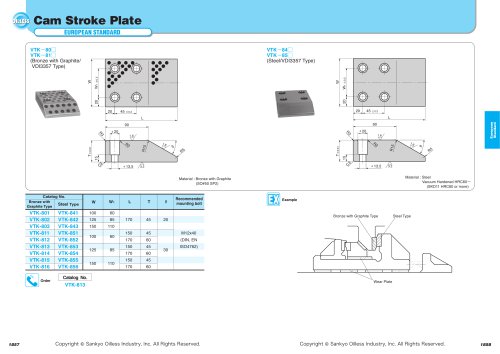

Catalog excerpts

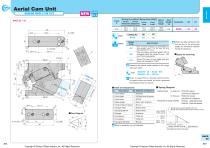

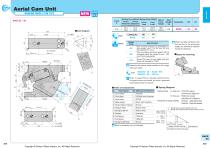

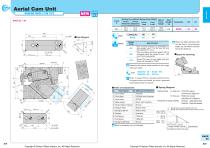

Aerial Cam Unit General Description of SACE( WORKING FORCE 3-TON TYPE ~) •The standard working force (one million strokes) achieved 29.4 kN with the mounting width of 52 mm. The allowable working force (300,000 strokes) is 58.8 kN. • I mproved durability of coil springs compared to old products.(SACD) •V-shaped guide. •Available angle is 0°to 60°at increments of 5° •Disassembly method of SACE52 1) Remove hexagon socket head bolt (©), and remove stopper plate (©). 2) Pull and remove cam slider (©) from cam holder (O) to the rear. •A ssembly method of SACE52 1)Assemble components in the reverse order of disassembly. • Make sure that there is no foreign matter on the sliding area and assemble components. • The clearance between the cam slider and the cam holder is controlled. Match the stamped serial number on the holder and slider before assembly. • When cam is disassembled and then reassembled,please do not forget to assemble all bolts provided. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserv

Open the catalog to page 1

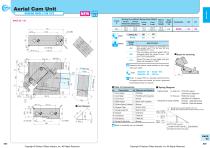

Aerial Cam Unit ( WORKING FORCE 3-TON TYPE ) rrm CAD FILE f ASACE 52 - 00 Travel S Option Code 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 00 - SC40 - N12 SACE52- 00 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load TF20-90(1 piece) 7.01N/mm(0.72kgf/mm) For Final Load TM30-50(1 piece) 109.65N/mm(11.18kgf/mm) • Guideline of spring durability TF20-90 1,000,000 strokes...

Open the catalog to page 2

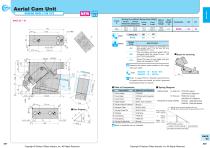

Aerial Cam Unit ( WORKING FORCE 3-TON TYPE ) rrm CAD FILE f ASACE 52 - 05 Travel S Option Code 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 05 - SC40 - N12 SACE52 - 05 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load TF20-90(1 piece) 7.01N/mm(0.72kgf/mm) For Final Load TM30-50(1 piece) 109.65N/mm(11.18kgf/mm) • Guideline of spring durability TF20-90 1,000,000 strokes...

Open the catalog to page 3

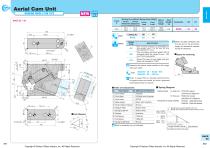

Aerial Cam Unit ( WORKING FORCE 3-TON TYPE Catalog No. | | (W) | — (K) SACE 52 - 10 Option Code 0 Determine the pierce center position in the range of the cam width. Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. ■ Spring Diagram • Spring Used For Initial Load For Final Load • Guideline of spring durability 0 Bolts for assembly are not indicated. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved. Copyright © Sankyo Oilless Industry, Inc. All Rights Reserved.

Open the catalog to page 4

Aerial Cam Unit ( WORKING FORCE 3-TON TYPE Catalog No. | | (W) | — (K) SACE 52 - 15 Option Code 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 15 - SC40 - N12 SACE52 - 15 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load TF20-90(1 piece) 7.01N/mm(0.72kgf/mm) For Final Load TM30-50(1 piece) 109.65N/mm(11.18kgf/mm) • Guideline of spring durability TF20-90 1,000,000 strokes...

Open the catalog to page 5

Aerial Cam Unit( WORKING FORCE 3-TON TYPE ) rrm CAD FILE Option Code □ When the slider interferes with the die due to the protrusion length, you will need to machine the die for clearance. 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 20 - SC40 - N12 SACE52 - 20 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load TF20-90(1 piece) 7.01N/mm(0.72kgf/mm) For Final Load...

Open the catalog to page 6

Aerial Cam Unit( WORKING FORCE 3-TON TYPE ) rrm CAD FILE Option Code 0 When the slider interferes with the die due to the protrusion length, you will need to machine the die for clearance. 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 25 - SC40 - N12 SACE52 - 25 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. Final 1425.5 Load (145.5) z877.2 (89.5) initial, Load 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load...

Open the catalog to page 7

Aerial Cam Unit ( WORKING FORCE 3-TON TYPE ) rrm CAD FILE f ASACE 52 - 30 Travel S Option Code 0 When the slider interferes with the die due to the protrusion length, you will need to machine the die for clearance. 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 30 - SC40 - N12 SACE52 - 30 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load TF20-90(1 piece)...

Open the catalog to page 8

Aerial Cam Unit( WORKING FORCE 3-TON TYPE ) rrm CAD FILE Option Code 0 When the slider interferes with the die due to the protrusion length, you will need to machine the die for clearance. 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 35 - SC40 - N12 SACE52 - 35 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring Used For Initial Load TF20-90(1 piece) 7.01N/mm(0.72kgf/mm) For Final Load...

Open the catalog to page 9

Aerial Cam Unit ( WORKING FORCE 3-TON TYPE ) rrm CAD FILE f ASACE 52 - 40 Travel S Option Code 0 When the slider interferes with the die due to the protrusion length, you will need to machine the die for clearance. 0 Determine the pierce center position in the range of the cam width. ■Space for removing SACE52 - 40 - SC40 - N12 SACE52 - 40 - WC120 Refer to page 559 for detailed specifications of tapped holes and dowel pin holes (prepared hole,finished hole) for retainer. Final 1425.5 Load (145.5) z997.8 (101.8) Initial Load 0 Bolts for assembly are not indicated. ■ Spring Diagram • Spring...

Open the catalog to page 10All SANKYO OILLESS INDUSTRY catalogs and technical brochures

-

PSCL,PSCM

1 Pages

-

SHPUC

3 Pages

-

TSHC

2 Pages

-

SACLB80

2 Pages

-

SUCD

18 Pages

-

SHCP

1 Pages

-

SNR41,42,43 Series

1 Pages

-

SFCU,SFCUB

1 Pages

-

CBSL,CBSPL

1 Pages

-

MCUW,MCUF,MCUS

1 Pages

-

TWP

1 Pages

-

Flange Lifter Pneumatic Type

1 Pages

-

Parallel Link Unit

1 Pages

-

Single Link Unit

1 Pages

-

Guide Roller Set Swing Type

1 Pages

-

Spherical Bush Set

1 Pages

-

Cam Slide Guide (L Type)

1 Pages

-

Cam Stroke Plate

1 Pages

-

Roller Cam Unit

2 Pages

-

Roller Cam Unit

2 Pages

-

Panel Input Detector Gauge

1 Pages

-

Panel Input Detector Gauge

1 Pages

-

Side Gauge

1 Pages

-

DA Gauge

1 Pages

-

Spring Plunger

1 Pages

-

Spring Plunger

1 Pages

-

Feed Sensor

1 Pages

-

Locating Cone

1 Pages

-

Shoulder Bolt

1 Pages

-

Slide Core Related Parts:VG2

1 Pages

-

Locking Block Augular Pin

1 Pages

-

Slide Plate Blank Type

1 Pages

-

Guide Bushing

2 Pages

-

Ejector Guide Bushing

1 Pages

-

Ejector Guide Pin

2 Pages

-

Automatic Blanking Die

4 Pages

-

Coil Support Economy Type

1 Pages

-

Side Gauge Air Drive Type

1 Pages

-

Die Materials

2 Pages

-

Aerial Cam Unit For Pierce

18 Pages

-

Slide Plate VSM SP2,ST

1 Pages

-

Lifting Hook(Eye Bolt)

1 Pages

-

Slide Unit for Loose Core

1 Pages

-

Shim Plate

1 Pages

-

Ball Guide Bushing

1 Pages

-

Guide Post Set Plain Type

1 Pages

-

Guide Post (Pulling Washer)

1 Pages

Archived catalogs

-

General Description of Cam Unit

20 Pages

-

Guide Post Set Components

1 Pages

-

centering wear slide rail

1 Pages

-

LARGE TYPE FOR PIERCE AND FLANGE

15 Pages

-

Ball Plunger

1 Pages

-

Ball ButtonYPress-Fit Button

1 Pages