Website:

Sankyo America

Website:

Sankyo America

Catalog excerpts

Precis Precision. Quality. Reliability.

Open the catalog to page 1

RollerDhve RA Series The Zero-Backlash Technology A mechanism developed through the pursuit of outstanding functionality and performance. Superior movement achieved with zero-backlash technology. With factory automation equipment using servo systems, overall machine performance can be greatly affected if critical element are not considered during the design. Factors, such as backlash can cause premature wear, vibration, inefficiencies, insufficient rigidity and control instability. Long settling times can affect productivity and positioning accuracy. Sankyo's innovative RA Series utilizes...

Open the catalog to page 2

The Zero-Backlash Technology In Pursuit of True High-Quality Motion RollerDrive RollerDrive motion ® Ideal motion Actual motion with distortion prone drives With previous motion equipment, the quality of motion was evaluated primarily based on accuracy and rigidity in the stationary state. These stationary characteristics are important, but in reality, accuracy and stability during movement have a large impact on the performance of factory automation equipment. In motion equipment with backlash or inferior response, motion does not proceed in accordance with control commands due to...

Open the catalog to page 3

5ROOHU'ULYH 6SHFL¿FDWLRQV Specification Sheet The RA series has two different lubrication options. Select the lubrication type by operation conditions. Grease lubrication can be used when low maintenance is required. The grease should last for the life of the unit. Oil lubrication should be selected when higher rated torque or higher speeds are required. To check that the service life of the RollerDrive will be satisfactory, please compare the specifications for each lubrication type. On the dynamic rated output torque curve (see page 5), when the point (Torque and Speed) is below the curve,...

Open the catalog to page 4

5ROOHU'ULYH 6SHFL¿FDWLRQV Dynamic Rated Output Torque The dynamic rated output torque is value of load torque for which an expected service life of 12,000 hours or greater is ensured. The dynamic rated output torque is dependent on the average output rotation speed. Oil lubrication type units have more speed capacity than grease filled lubrication types. Note; oil filled units are special order & deliveries may be affected. RA63 Gear ratio Gear ratio Average output rotation speed rpm Gear ratio Gear ratio Average output rotation speed rpm 20 30 40 50 Average output rotation speed rpm 20 25...

Open the catalog to page 5

5ROOHU'ULYH 6SHFL¿FDWLRQV (I¿FLHQF\ This indicates the percent of input power which is transmitted to the output. The RollerDrive motion mechanism has high efficiency because it employs rolling contact. Efficiency varies depending on conditions such as load torque, rotation speed and temperature. ® RA63 Output rotation speed Output rotation speed 100 RA100 Output rotation speed 100 Output rotation speed 100 Output rotation speed 100

Open the catalog to page 6

5ROOHU'ULYH 6SHFL¿FDWLRQV Torsional Rigidity Torsional rigidity is the ease with which the shaft twists in response to output shaft torque, and is expressed as the slope of the line connecting the two points for 50% and 100% rated torque on the hysteresis curve (reference page 26). The higher the torsional rigidity, the smaller the deformation in response to torque, and the higher the natural frequency. RA63 0.008 Output shaft twists rad. Output shaft twists rad. Loaded output shaft torque N m RA100 Output shaft twists rad. Loaded output shaft torque N m Loaded output shaft torque N m RA125...

Open the catalog to page 7

Model Code Model Code Gear ratio Lubrication and mounting position Servomotor position Servomotor fastener elements Special Instructions See list of "Mounting position" code T : Mounted on right side as viewed from front as viewd from front Please don't fill if there are standard spec shown in this catalog. *1 Denotes non-standard option, please contact Sankyo sales for special ratio options, mouning or servo motor brands not listed. About Installation of Servo Motor Installing a servo motor to the RollerDrive should be done by the customer. The instruction manual is included with the...

Open the catalog to page 8

Model Code Compatible Servomotors Please prepare the servo motor with no keyway.

Open the catalog to page 9

VW surface VW surface * see page 16 The relationship of the input/output shaft rotation directions is a-d, b-c Dowel holes on output table surface are drilled with reference to outside diameter of output shaft flange (φ30h7) and M5 tapped hole. Dowel holes on surface V,W are drilled with reference to center of output shaft (φ30h7) and Surface R. View from Mounting position Servomotor position Position of Oil Level and Oil Plug and Drain (Oil Lubrication)

Open the catalog to page 10

* Motor base * see page 18 The relationship of the input/output shaft rotation directions is a-d, b-c. Dowel holes on output table surface are drilled with reference to outside diameter of output shaft flange (φ60h7) and M6 tapped hole. Dowel holes on surface V,W are drilled with reference to center of output shaft (φ60h7) and Surface R. View from Mounting position Servomotor position Position of Oil Level and Oil Plug and Drain (Case of Oil Lubrication) A

Open the catalog to page 11

Motor base * see page 20 The relationship of the input/output shaft rotation directions is a-d, b-c. Dowel holes on output table surface are drilled with reference to outside diameter of output shaft flange (φ 85h7) and M8 tapped hole. Dowel holes on surface V,W are drilled with reference to center of output shaft (φ 85h7) and Surface R. Position of Oil Level and Oil Plug and Drain (Oil Lubrication) R R surface side U U surface side Mounting position Servomotor position View from

Open the catalog to page 12

* see page 22 The relationship of the input/output shaft rotation directions is a-d, b-c. Dowel holes on output table surface are drilled with reference to outside diameter of output shaft flang (φ95h7) and M10 tapped hole. Dowel holes on surface V,W are drilled with reference to center of output shaft (φ95h7) and Surface R. Position of Oil Level and Oil Plug and Drain (Oil Lubrication ) A 1 Mounting position Servomotor position View from

Open the catalog to page 13All Sankyo America catalogs and technical brochures

-

Do Series, Ring Indexer

4 Pages

-

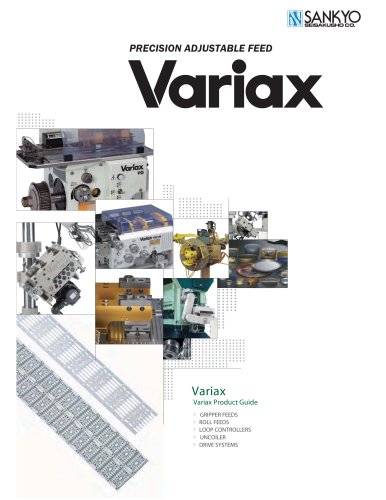

Coil Feeds for Presses

23 Pages

-

RE Series Catalog

20 Pages

-

RA Series Catalog

22 Pages

-

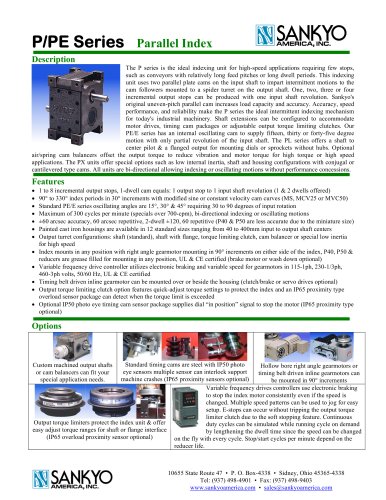

P Series Catalog

2 Pages

-

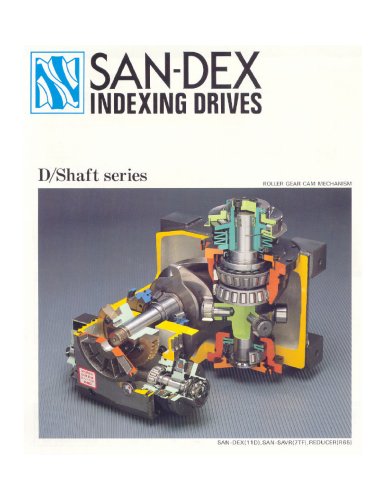

D Series Catalog

24 Pages

-

ED Series Catalog

1 Pages

-

DT/RT/DTR Series Catalog

5 Pages

-

TC Series Catalog

11 Pages

-

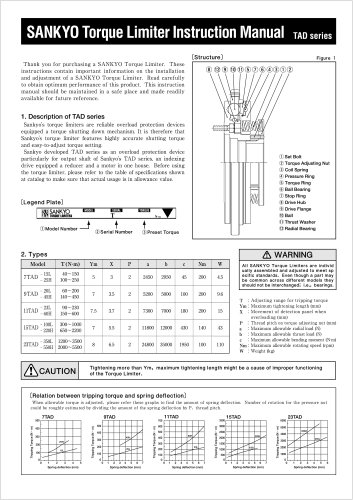

TAD Alpha Catalog

2 Pages

-

GY Series Catalog

20 Pages

Archived catalogs

-

Alpha Series Catalog

25 Pages

-

Eco Series ED Catalog

32 Pages

-

Alpha Servo Catalog

18 Pages

-

LM Series Catalog

8 Pages

-

DF, EF & RF Series Catalog

19 Pages

-

D, E & R Series Catalog

18 Pages