Website:

Sankyo America

Website:

Sankyo America

Catalog excerpts

GOOD DESIGN

Open the catalog to page 1

Superior movement achieved with zero-backlash technology The RotlerDrivB RA Series provides high-quality movement, precise to input control commands, using zero-backlash technology. In FA equipment, motion control using servo systems is a crucial element which greatly affects equipment performance. Naturally, equipment specifications and performance are designed assuming that the expected motion is attained, but if there are factors such as backlash, insufficient rigidity or control instability in the motion control section, then output motion will deviate from input control commands, and...

Open the catalog to page 3

RollerDrive RA series The "ZERO-Backlash" Technology 3

Open the catalog to page 4

RollerDrive Output shaft Basic structure Preload The RollerDrive is an orthogonal Wedge-shaped input shaft ribs reducer which transmits rotation make contact with roller follow- through contact between a screw ers in the preload state, and this shaped input shaft, and multiple roll- completely eliminates backlash. er followers arranged in a radiating Preload is adjusted using an pattern on the output shaft. adjustment mechanism on the input shaft side. Input shaft Input shaft Roller followers In order to meet stringent accuracy These are roller bearing structures requirements, the alloy...

Open the catalog to page 5

RollerDrive specifications Permissible output shaft load The RollerDrive RA Series has a built-in cross roller bearing for output. Please use within a range not exceeding the permissible radial, axial and moment load in the following Table. Method of calculating moment load

Open the catalog to page 6

Standard servomotor specifications List of mountable servomotors The following motors can be mounted to the RollerDrive RA Series. The Series is also compatible with geared servomotors from each company for high gear ratios. If you want to mount a motor other than a standard motor, please consult with us.

Open the catalog to page 7

MODEL CODE MODEL CODE Please write in codes 8 and 9 (option) if you want the option provided.□ Please write in code 10 if there are special specifications. Please notify us of the content of the special specifications. | Input shaft torsion (V-surface side) The surfaces of the RollerDrive main body are indicated as follows by letters of the alphabet. | Motor position code | Code for dowel hole in output table surface | Code for dowel hole in housing (Please discuss with our company) • If a non-standard gear ratio Is necessary • If you only need the reducer • If you want to mount another...

Open the catalog to page 8

Selection, Capacity check Selection method Loaded torque graph Check torque and rotation speed at start-up, dur- ing steady operation, and at stopping. The average value in the operation interval is used for the rotation speed N. Find conditions Find the average loaded torque from the loaded torque graph. Average output rotation speed Average input rotation speed Maximum input rotation speed mean — "mean nmean><i (Gear ratio) (rpm) ■^max = nmax (Maximum output rotation speed) xi (Gear ratio) (rpm) Selection is completed when the required specifications are met

Open the catalog to page 9

Dimensions RA40 Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. RA63 Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. 9

Open the catalog to page 10

RollerDrive RA80 Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. RA80 Medium inertia servomotor specifications Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. 10

Open the catalog to page 11

Dimensions RA100 Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. RA100 Medium inertia servomotor specifications Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. 11

Open the catalog to page 12

RollerDrive RA125 Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. RA125 Medium inertia servomotor specifications Dowel hole drilling in output table surface (Option) Dowel hole drilling in housing (Option) The relationship of the input/output shaft rotation directions is a-d, b-c (L cam). Dowel hole drilling is an option. Please indicate with the product code. 12

Open the catalog to page 13

Technical information Backlash, lost motion, hysteresis loss For a general reducer, the following hysteresis graph can be obtained by applying torque to the output shaft, and plotting the generated torsion angle. Backlash, lost motion and hysteresis loss can each be defined from the hysteresis graph, as indicated below. Backlash: Rotation angle which can arise even with zero torque (looseness) Lost motion: Torsion angle of the midpoint of the hysteresis curve width which arises when applying ±3% rated torque Hysteresis loss: Torsion angle where there is no complete return, when torque is...

Open the catalog to page 14

RollerDrive Torsional rigidity Torsional rigidity is the ease with which the shaft twists in response to output shaft torque, and is expressed as the slope of the line connecting the two points for 50% and 100% rated torque on the hysteresis curve (y/x in the graph on the previous page). The higher the torsional rigidity, the smaller the deformation in response to torque, and the higher the natural frequency. RA40 RA63 RA80 RA100 RA125 14

Open the catalog to page 15All Sankyo America catalogs and technical brochures

-

The Zero-Backlash Technology

32 Pages

-

Do Series, Ring Indexer

4 Pages

-

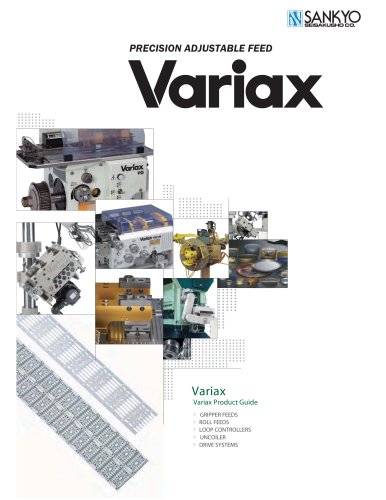

Coil Feeds for Presses

23 Pages

-

RE Series Catalog

20 Pages

-

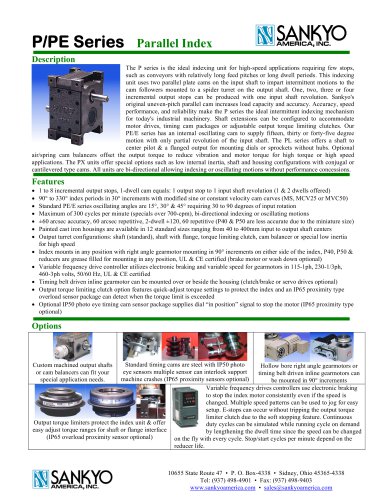

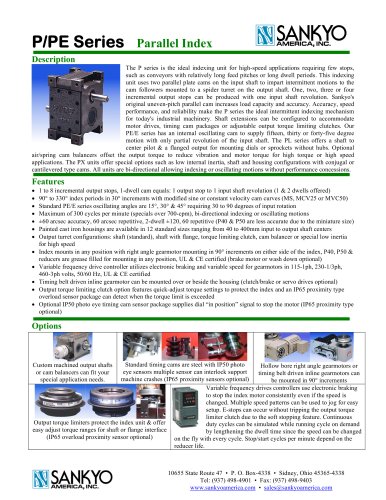

P Series Catalog

2 Pages

-

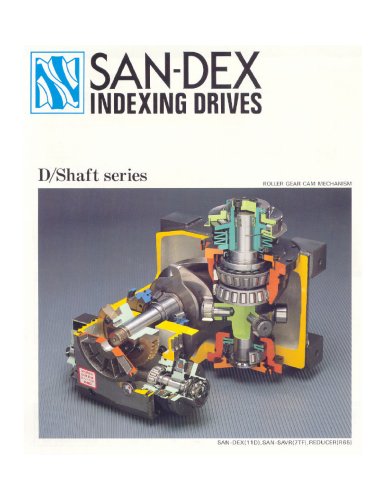

D Series Catalog

24 Pages

-

ED Series Catalog

1 Pages

-

DT/RT/DTR Series Catalog

5 Pages

-

TC Series Catalog

11 Pages

-

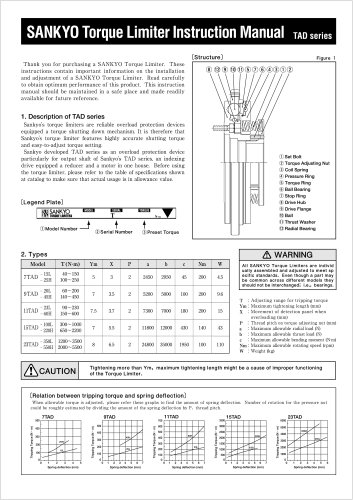

TAD Alpha Catalog

2 Pages

-

GY Series Catalog

20 Pages

Archived catalogs

-

Alpha Series Catalog

25 Pages

-

Eco Series ED Catalog

32 Pages

-

Alpha Servo Catalog

18 Pages

-

LM Series Catalog

8 Pages

-

DF, EF & RF Series Catalog

19 Pages

-

D, E & R Series Catalog

18 Pages