Website:

Sankyo America

Website:

Sankyo America

Catalog excerpts

DT/RT/DTR Series Dial Index Description Sankyo's DT/RT/DTR series features a low profile design cast iron housing with a ground pilot flange for mounting dial plates, hub less gears, or weldment fixtures. Above the indexing dial, a second dial mounting surface is stationary and hollow to allow air lines, wiring or bearings for a shaft to be routed through the tolerance bore. A globoidal cam rotates Sankyo made needle bearing type cam followers. Optimizing the cam follower diameter inherently maximizes torque transfer and extends the life hours due to fewer rotations with increased surface contact. Our DT series offers multiple index periods to run continuous mode or “on demand’ duty cycles with the indexing flange locking in position within 30 arc seconds during each dwell period. The output flange turret is mounted with top and bottom tapered bearings which supports large bending moments, maintain rigidity and reliability. These versatile units index in both directions or oscillate by reversing the motor using a VFD (variable frequency drive) controller. The RT series is capable of performing non-patterned motions in forward or reverse direction with a continuous lead cam using programmable servo driven motors. Motor drive options include inexpensive gearmotors, Sankyo’s R series low backlash worm drive reducer that is compatible with servo motors or belt driven reducer on the larger units. Sizes 8, 11, 14, 18 & 25DT are offered with an optional output torque limiting clutch. Mounting between the index and the rotating dial, it features an adjustable torque range without disassembly and overload detection. Timing cam packages are available with inexpensive photo beam sensors or proximity switches for wash down (IP67/NEMA-6P) applications. The large dial index DTR series has the same internal components as the DT series but includes an innovative integrated reducer that allows the motor to be mounted on the right, left or with 2 motors (as shown). The internal reducer is a low backlash worm type compatible with high torque motors. Dual flange motors can mount directly to the index housing to increase the horsepower but still keep a small footprint. The input shaft is free to drive other peripheral equipment to stay synchronized with the indexing dial. The input can also drive our patented cam balancer (shown left) to offset the output load torque causing the motor torque requirement to be much less. Horsepower that was used to rotate the output load can be partially redirected to increasing the acceleration or decrease the deceleration. Fast index times can be achieved with small motor torque requirements. Large loads can be rotated with a less expensive smaller housing size to minimize the footprint. An inherent problem of rotating large indexing dials is waiting for the dial to settle or become motionless. The overall machine throughput will increase because the work done on the dial can be started sooner. Since the cam balancer torque compensation is adjusted with air pressure, fluctuating output loads can be accommodated with a turn of the air regulator. Air consumption is minimal, its equivalent of filling an air cylinder reservoir but not cycling it, its only uses air if the regulator is adjusted. Output backlash is minimized to reduce vibration which enhances the life and accuracy of the unit. Based on the advantages of the cam balancer, justifying this option is simple. Features • • • • • • • • • • • • • 4 to 96 incremental output stops, 1-dwell cam equals; 1-output stop to 1-input shaft revolution, 2-dwells for 48 to 64 stops Dial diameters range from 320mm to 6400mm (1 to 21 feet) 90° to 330° index periods with modified sine cam curve Maximum 200 cycles per minute, bi-directional indexing, oscillating motions (non-pattern the servo driven RT series) ±30 arcsec indexing accuracy, 30 arcsec repetitive for 8~25DT, ±60 arcsec for 2-dwell cams (±20 arcsec for 35~80DT) Painted cast iron housings are available in 11 standard sizes ranging from 80 to 800mm input to output shaft centers Standard stationary hollow flange output with tolerance bore (available with optional torque limiting clutch up to 25DT) Standard brushless dual voltage (230/460) gearmotors are UL & CE certified, brake motor or wash down optional Variable frequency drive controller utilizes electronic braking and variable speed for gearmotors in 115-1ph, 230-1/3ph, 460-3ph volts, 50/60 Hz, UL & CE certified Stop/start frequency up to 60~90 per minute (output load/reducer dependant), clutch brake or servo drives are available Standard IP50 photo eye timing cam sensor package supplies dial “in position” signal to stop the motor, IP67 proximity type optional Output torque limiting clutch option features quick-adjust torque setting, automatic reset every 360° & overload detect prox. Cam balancer options offers input torque compensation to minimize motor horsepower requirements 10655 State Route 47 • P. O. Box-4338 • Sidney, Ohio 45365-4338 Tel: (937) 498-4901 • Fax: (937) 498-9403 www.sankyoamerica.com • sales@sankyoamerica.com

Open the catalog to page 1

DT/RT/DTR Series Specifications Model Dial Diameter mm (inch) Dial Pilot Bore mm (inch) Hollow Bore Dia. mm (inch) Max. Axial Load N (lb) Max. Radial Load kg (lb) Shaft Center Dist. mm (in) Index Housing Output Type Indexing Stops Quick Reference Chart 8DT 11DT 14DT 18DT 25DT 35DT 45DTR 55DTR 65DTR 72DTR 80DTR 640 (25.1”) 880 (34.6”) 1120 (44.0”) 1440 (56.7”) 2000 (78.7”) 2800 (110.2”) 3600 (142”) 4400 (173.2”) 5200 (204.7”) 5760 (226.7”) 6400 (251.9”) 90 (3.54”) 120 (4.72”) 150 (5.90”) 190 (7.48”) 260 (10.23”) 380 (14.96”) 460 (18.11”) 540 (21.25”) 600 (23.62”) 600 (23.62”) 700 (27.55”) 30...

Open the catalog to page 2

DT/RT/DTR Series Dial Index Stationary Output Flange Riser Option This option is used if part handlers or measurement equipment are required to be mounted above the rotary indexing dial. The riser is flanged on both ends and offered in multiple lengths with a slightly smaller hollow bore than the index bore. Each riser incorporates a tolerance male centering pilot on the index output flange and for the dial plate or fixture mounting flange. The riser is mounted to the index output flange with (4) bolts and also includes the grease fitting to be extended for easy access. Standard units are...

Open the catalog to page 3All Sankyo America catalogs and technical brochures

-

The Zero-Backlash Technology

32 Pages

-

Do Series, Ring Indexer

4 Pages

-

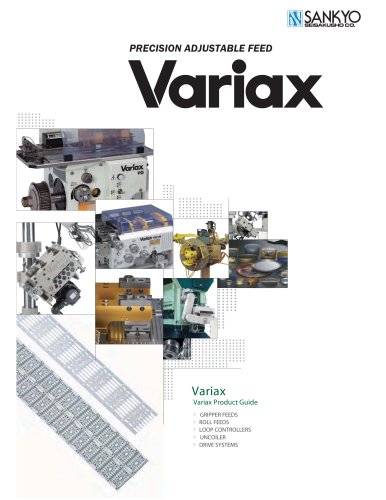

Coil Feeds for Presses

23 Pages

-

RE Series Catalog

20 Pages

-

RA Series Catalog

22 Pages

-

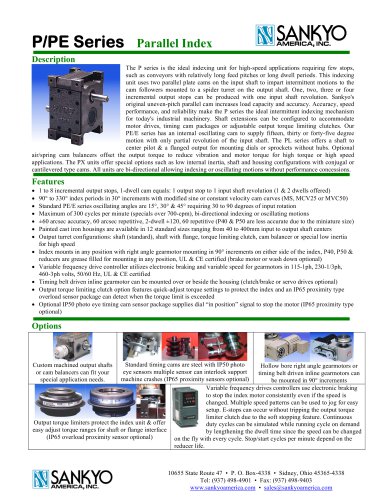

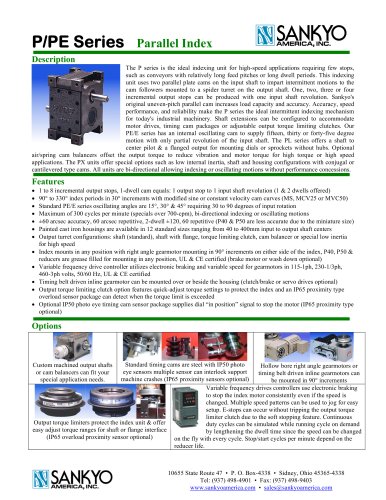

P Series Catalog

2 Pages

-

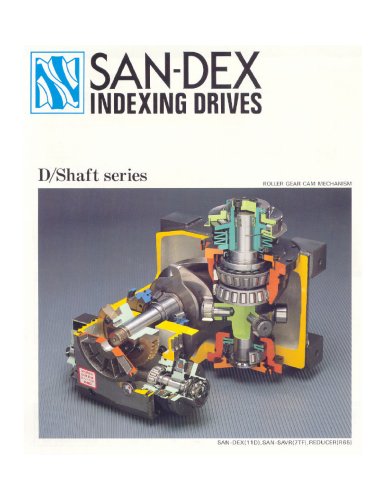

D Series Catalog

24 Pages

-

ED Series Catalog

1 Pages

-

TC Series Catalog

11 Pages

-

TAD Alpha Catalog

2 Pages

-

GY Series Catalog

20 Pages

Archived catalogs

-

Alpha Series Catalog

25 Pages

-

Eco Series ED Catalog

32 Pages

-

Alpha Servo Catalog

18 Pages

-

LM Series Catalog

8 Pages

-

DF, EF & RF Series Catalog

19 Pages

-

D, E & R Series Catalog

18 Pages