Website:

Sankyo America

Website:

Sankyo America

Catalog excerpts

Variax Variax Product Guide GRIPPER FEEDS ROLL FEEDS LOOP CONTROLLERS UNCOILER DRIVE SYSTEMS

Open the catalog to page 1

VARIAX is a generic name for high performance, high-speed press feeds and related products and systems. With a goal to meet different requirements in the press industry, we combined the latest know-how with an innovative product concept based on Sankyo’s unique cam technology. These feeds use our roller gear cam in the drive to create the world’s fastest feeds from Sankyo’s original motion curve and drive mechanism. In addition, with their excellent operability and user-friendliness, including easy parameter adjustments such as feed length, material thickness, grip force and roll...

Open the catalog to page 2

Cam type roll feed for high-speed and high-precision. Primary performance Conformable material shapes chain.motor core.rotor coil, clutch plate, spring parts, bearing retainer etc. Loop Controller Loop Controller / Straightener Increased productivity with correction. Primary performance Conformable material shapes motor core.power transistor.connector etc. Loop Controller Producing the ideal material loop. Primary performance Conformable material shapes

Open the catalog to page 3

VG series Feed with a soft touch. Reliable, high-speed gripper gives excellant results. This unit feeds materials by gripping them. The combination of four cam mechanisms provides high speed, high precision, and high reliability. Unlike roll feeders that feed materials by rotating the rollers, a gripper feed uses the coefficient of friction to grip materials. Therefore, a gripper feed makes it possible to feeding materials with different shapes and also soft materials. It will not create pressure scars or flaws on materials, feeds in fine increments if desired and can feed at super-high...

Open the catalog to page 4

VGX series New type grip feed with adjustable release timing using a dial. To make adjustments without tools, to make fine adjustments during operation, to supply material at creep speeds, the new cam-driven grip feed is exactly what you want. It was developed from the results and experience we have established to improve work safety and operate at high speed. In addition to the excellent features (high-speed, high-precision feeding, and hard to scare materials) of the VG series, this series lets you adjust for material thickness, feed length, and release timing without needing any tools....

Open the catalog to page 5

V series Cam type roll feed for high-speed and high-precision. This is a high-performance cam type variable roll feed that uses fan-shaped roller segment and four cams. Its feeding precision, excellant operability and workability are widely respected. This feed employs unique and new technologies such as a roller drive on both edges, a parallel level adjustment function between the roller and the clamper, and an absolute digital counter that displays the feed length precisely. Even though more than 30 years have passed since this model was developed, it is still in wide use with presses...

Open the catalog to page 6

VSC /VLC series Producing the ideal material loop. Sankyo developed the NC loop controller in order to create the ideal loop shapes required by the feeding device, using servo technology. This VLC sets up optimum feeding by forming ideal loops in the space allowed, taking advantage of the spring characteristics of materials and stabilizing the loop using a sensor and servo control. The VLC has excellent handling characteristics in that it does not scratch, kink or dent material and can improve both quality and productivity. Employs a high-resolution high-torque servo motor drive. Eliminates...

Open the catalog to page 7

Drive units V.S.D. (Variax Servo Drive system) The servo drive system is excellent for synchronized performance. VSD Variax Servo Drive The VSD (Variax Servo Drive) was developed specifically to drive cam feed units with servomotors. In order to achieve compliance with the start/stop characteristics of a press, our proprietary, newly-developed controller was integrated into the system to offer excellent synchronized performance. And, since the feed timing and indexing angle can be easily changed, it is being installed on more and more Variax products. S.C.T. (Self-Compensating Tensioning...

Open the catalog to page 8

STANDARD SPEED/WEIGHT CHARTS

Open the catalog to page 12

STANDARD SPEED/WEIGHT CHARTS

Open the catalog to page 13

VGX30, VGX60, VGX-30/60/100 VGX100 STANDARD LEFT TO RIGHT PUSH FEED SHOWN GUIDE ROLLER FOR STOCK WIDTH LOWER GRIP JAW LOWER BRAKE JAW 0 19 (.75”) 0 OPTIONAL STOCK CATENARY 60 (2.36”) BACK VIEW 155 (6.10”) OIL IN BSPT1/4 250 (9.84”) INPUT SHAFT GUIDE PLATE GUIDE BASE 280 (11.00”) OIL OUT BSPT3/4 THICKNESS INDICATOR FEED PITCH INDICATOR RELEASE TIMING INDICATOR OFFSET GUIDE ADJUSTMENT DIAL GUIDE LOCKING LEVER STOCK WIDTH ADJUSTMENT DIAL 225 FEED LEVEL (8.86”) UPPER STOCK GUIDE ENGAGED WITH THICKNESS ADJUSTMENT 14 ELECTRIC POWER INLET AIR IN BSPT1/4 45 (1.77”) 0 410 (16.14”) 530 (20.87”) 342.5...

Open the catalog to page 14

STANDARD SPEED/WEIGHT CHARTS p Specific Weight kg/ms

Open the catalog to page 15

VG SERIES STANDARD GRIP AND BRAKE VG15H, VG20H, VG25, VG50, VG75, VG100 OPTIONAL MICRO-ADJUST GRIP AND BRAKE VG25T, VG50T, VG75T, VG100T 16

Open the catalog to page 16

V76 STANDARD LEFT TO RIGHT PUSH FEED SHOWN OIL DRAIN TAP 18 DEEP OIL OUT OIL IN OIL OUT OUTLET GUIDE INLET GUIDE AIR IN TAP 18 DEEP OIL DRAIN TAP INLET GUIDE OUTLET GUIDE 17 TAP

Open the catalog to page 17

V127W STANDARD LEFT TO RIGHT PUSH FEED SHOWN OIL OUT OIL IN OIL IN SECTOR ROLL OIL OUT OUTLET GUIDE INLET GUIDE AIR IN CENTER LINE OF SECTOR ROLLS CENTER LINE OF 245mm MATERIAL TAP 25 DEEP OIL DRAIN TAP TAP OUTLET GUIDE INLET GUIDE 18

Open the catalog to page 18

V230W STANDARD LEFT TO RIGHT PUSH FEED SHOWN OIL OUT OIL IN AIR IN PIPE O.D. OIL IN INLET GUIDE OIL OUT CENTER LINE OF 100mm MATERIAL OUTLET GUIDE TAP 40 DEEP OIL DRAIN INLET GUIDE OUTLET GUIDE 19 OIL OUT

Open the catalog to page 19

STANDARD SPEED/WEIGHT CHARTS p Specific Weight kg/rrv

Open the catalog to page 20

Metal or Alloy Density (kg/m 3 ) Metal or Alloy Admiralty Brass 8525 Lead 11340 Aluminum 2712 Light alloy based on Al 2560 - 2800 Aluminum - melted 2560 - 2640 Light alloy based on Mg 1760 - 1870 Aluminum bronze (3-10% Al) Aluminum foil Antifriction metal Antimony Beryllium Beryllium copper Bismuth Brass - casting Brass - rolled and drawn Brass 60/40 Bronze - lead Bronze - phosphorous Bronze (8-14% Sn) Cadmium Cast iron Chemical Lead Chromium Cobalt Constantan Copper Cupronickel Delta metal Electrum Gold Hatelloy Inconel Incoloy Iron 7700 - 8700 2700 -2750 9130 -10600 6690 1840 8100 - 8250...

Open the catalog to page 21All Sankyo America catalogs and technical brochures

-

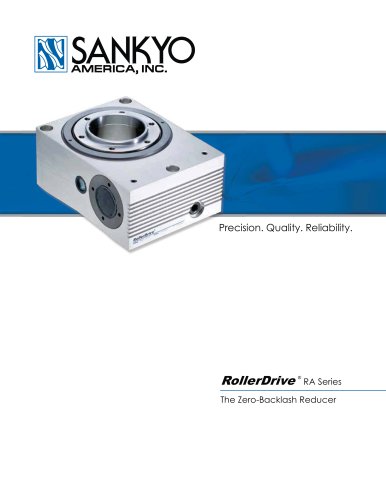

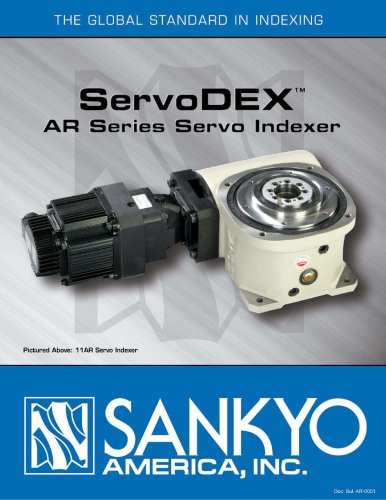

The Zero-Backlash Technology

32 Pages

-

Do Series, Ring Indexer

4 Pages

-

RE Series Catalog

20 Pages

-

RA Series Catalog

22 Pages

-

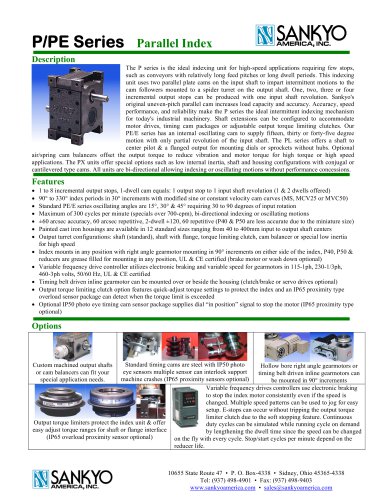

P Series Catalog

2 Pages

-

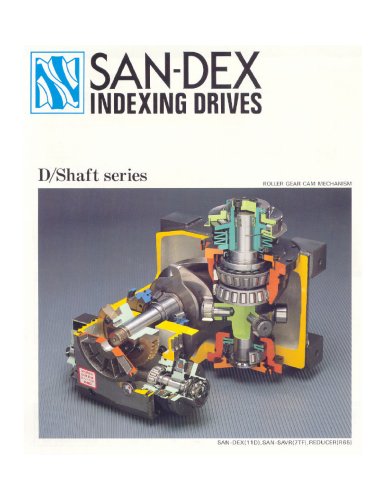

D Series Catalog

24 Pages

-

ED Series Catalog

1 Pages

-

DT/RT/DTR Series Catalog

5 Pages

-

TC Series Catalog

11 Pages

-

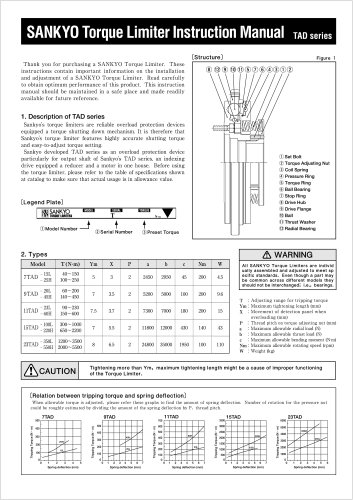

TAD Alpha Catalog

2 Pages

-

GY Series Catalog

20 Pages

Archived catalogs

-

Alpha Series Catalog

25 Pages

-

Eco Series ED Catalog

32 Pages

-

Alpha Servo Catalog

18 Pages

-

LM Series Catalog

8 Pages

-

DF, EF & RF Series Catalog

19 Pages

-

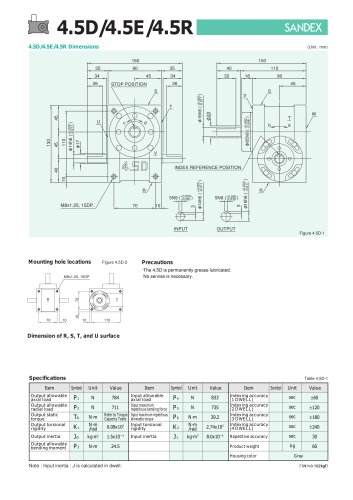

D, E & R Series Catalog

18 Pages