Catalog excerpts

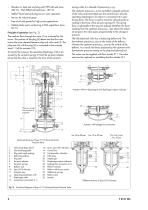

T 2517 EN Type 41-73 Universal Excess Pressure Valve Self-operated Pressure Regulators Application Pressure regulators for set points from 0.05 to 28 bar · Valve nominal sizes DN 15 to 100 · Nominal pressure PN 16 to 40 Suitable for liquids, gases and vapors up to 350 °C The valve opens when the upstream pressure rises. Special features •• Low-maintenance proportional regulators requiring no auxiliary energy •• Frictionless plug stem seal with stainless steel bellows •• Control line kit available for tapping the pressure directly at the valve body •• Wide set point range and convenient set point adjustment using a nut •• Exchangeable actuator and set point springs •• Spring-loaded, single-seated valve with upstream and downstream pressure balancing 1) by a stainless steel bellows •• Soft-seated plug for high shut-off requirements •• Low-noise standard plug •• All wetted parts free of non-ferrous metal Versions Excess pressure valve for controlling the upstream pressure p1 to the adjusted set point. The valve opens when the upstream pressure rises. –– Type 41-73 · Standard version Type 2417 Valve · Valve DN 15 to 100 · Metal-seated plug · Body made of cast iron EN-GJL-250, spheroidal graphite iron EN-GJS-400-18-LT, cast steel 1.0619 or CrNiMo steel 1.4408 Type 2413 Actuator with EPDM rolling diaphragm Version with additional features –– Excess pressure valve with increased safety Actuator with leakage line connection and seal or two diaphragms and diaphragm rupture indicator Fig. 1: Type 41-73 Universal Excess Pressure Valve Special versions –– Control line kit for tapping the pressure directly at the valve body (accessories) –– With internal parts made of FKM, e.g. for use with mineral oils –– EPDM diaphragm with PTFE protective facing –– Actuator for remote set point adjustment (autoclave control) –– Bellows actuator for valves in DN 15 to 100 · Set point ranges 2 to 6, 5 to 10, 10 to 22 or 20 to 28 bar With KVS ≤ 4: without balancing bellows –– Valve with flow divider ST 1 for particularly low-noise operation with gases and vapors –– Version entirely of stainless steel SAMSON AKTIENGESELLSCHAFT · Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Pho

Open the catalog to page 1

–– Stainless Cr steel seat and plug with PTFE soft seal (max. 220 °C) · With EPDM soft seal (max. 150 °C) springs when it is relieved of pressure (p1= p2). The upstream pressure p1 to be controlled is tapped upstream of the valve and transmitted over the control line (14) to the operating diaphragm (12) where it is converted into a positioning force. This force is used to move the valve plug (3) according to the force of the set point springs (7). The spring force is adjustable at the set point adjuster (6).When the force resulting from the upstream pressure p1 rises above the adjusted set...

Open the catalog to page 2

Valve for small flow rates KVS ≤ 4: without balancing bellows 2 Plug with metal sealing, with flow divider ST 1 Plug with soft seal 3.2 Plug with soft seal 3.3 Flow divider Fig. 3: Equipment, seat/plug versions Table 1: Technical data · All pressures in bar (gauge) Valve Nominal pressure Nominal size Max. perm. differential pressure ∆p Max. permissible temperature Valve plug See pressure-temperature diagram in u T 2500 Metal seal: 350 °C · PTFE soft seal: 220 °C · EPDM or FKM soft seal: 150 °C · NBR soft seal: 80 °C Metal seal: leakage rate I (≤0.05 % of KVS) Leakage class according to IEC...

Open the catalog to page 3

Ordering text Type 41-73 Universal Excess Pressure Valve Additional features ... DN ... Body material ..., PN ... Kvs ... Set point range ... bar Optionally, accessories ... ( T 2595) Optionally, special version ... Installation Normally, the valve is installed with the actuator suspended downwards. Install pipelines horizontally with a slight downward slope on both sides of the valve for drainage of the condensate. - The direction of flow must correspond with the arrow on the valve body. - The control line must be adapted to match the onsite conditions and is not delivered with the valve....

Open the catalog to page 4

Table 5: Dimensions in mm and weights in kg Excess pressure valve Valve size 335 Cast steel Forged steel Standard version with Type 2413 Actuator with rolling diaphragm Height H 0.05 to 0.25 bar Valve spring force F Valve spring force F Valve spring force F Valve spring force F Actuator Valve spring force F Valve spring force F 0.1 to 0.6 bar Valve spring force F Weight for version with rolling diaphragm 0.05 to 0.6 bar 0.2 to 2.5 bar 2 to 16 bar Weight, based on cast iron 1), approx. kg Version with Type 2413 Bellows Actuator Height H 2 to 6 bar Valve spring force F Valve spring force F...

Open the catalog to page 5

Table 6: KVS coefficients and xFZ values · Terms for noise level calculation according to VDMA 24422 (edition 1.89) Nominal size Standard version With flow divider Special version KVS ≤4: valve without balancing bellows Max. permissible ∆p: 25 bar Valve-specific correction terms Values as specified in the diagram Terms for control valve sizing according to IEC 60534, Parts 2-1 and 2-2: xFZ · Acoustical valve coefficient KVS 1 · When a flow divider ST 1 is installed as a noise-reducing component Flow characteristic differences between valves with and valves without flow dividers do not...

Open the catalog to page 6All SAMSON catalogs and technical brochures

-

TROVIS 5590 Web Module

2 Pages

-

Room Controller TROVIS 5572

2 Pages

-

Room Panel TROVIS 5570

2 Pages

-

Line Splitter TROVIS 5486

2 Pages

-

Type 9 Temperature Regulator

6 Pages

-

Type 8 Temperature Regulator

6 Pages

-

Type 5 D Boiler Controller

2 Pages

-

Rotary Plug Valve Type 62.7

7 Pages

-

Actuator Type S

3 Pages

-

Actuator Type MZ

4 Pages

-

Actuator Type MN

3 Pages

-

Actuator Type MD

3 Pages

-

Actuator Type R

3 Pages

-

Actuator Type AT

4 Pages

-

Rotary Plug Valve Type 82.7

7 Pages

-

Rotary Plug Valve Type 73.7

7 Pages

-

Rotary Plug Valve Type 73.3

7 Pages

-

Rotary Plug Valve Type 72.4

7 Pages

-

Rotary Plug Valve Type 72.3

8 Pages

-

SAMSON Positioners

28 Pages

Archived catalogs

-

T21 11

6 Pages