Catalog excerpts

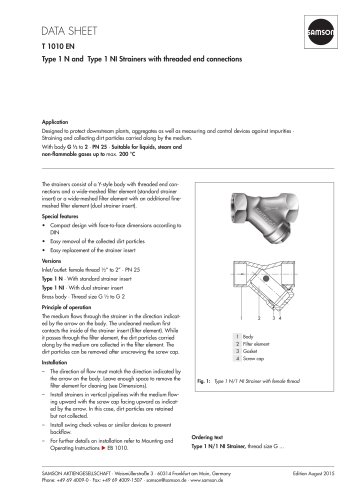

T 1010 EN Type 1 N and Type 1 NI Strainers with threaded end connections Application Designed to protect downstream plants, aggregates as well as measuring and control devices against impurities · Straining and collecting dirt particles carried along by the medium. With body G ½ to 2 · PN 25 · Suitable for liquids, steam and non-flammable gases up to max. 200 °C The strainers consist of a Y-style body with threaded end connections and a wide-meshed filter element (standard strainer insert) or a wide-meshed filter element with an additional finemeshed filter element (dual strainer insert). Special features •• Compact design with face-to-face dimensions according to DIN •• Easy removal of the collected dirt particles •• Easy replacement of the strainer insert Versions Inlet/outlet: female thread ½” to 2” · PN 25 Type 1 N · With standard strainer insert Type 1 NI · With dual strainer insert Brass body · Thread size G ½ to G 2 Principle of operation The medium flows through the strainer in the direction indicated by the arrow on the body. The uncleaned medium first contacts the inside of the strainer insert (filter element). While it passes through the filter element, the dirt particles carried along by the medium are collected in the filter element. The dirt particles can be removed after unscrewing the screw cap. 1 Body 2 Filter element 3 Gasket 4 Screw cap Installation –– The direction of flow must match the direction indicated by the arrow on the body. Leave enough space to remove the filter element for cleaning (see Dimensions). Fig. 1: Type 1 N/1 NI Strainer with female thread –– Install strainers in vertical pipelines with the medium flowing upward with the screw cap facing upward as indicated by the arrow. In this case, dirt particles are retained but not collected. –– Install swing check valves or similar devices to prevent backflow. –– For further details on installation refer to Mounting and Operating Instructions u EB 1010. Ordering text Type 1 N/1 NI Strainer, thread size G ... SAMSON AKTIENGESELLSCHAFT · Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Phone: +49 69 4009-0 · Fa

Open the catalog to page 1

Table 1: Technical data Version Thread size Flow resistance coefficient Free filter area Approx. 3 times pipe cross-section Mesh size Flow resistance coefficient Free filter area Approx. 2.5 times pipe cross-section Table 2: Materials Type ... Stainless steel 1.4401 Novatec® Premium Table 3: Dimensions in mm and weights Pressure-temperature diagram Brass body · PN 25 Thread size H2 (strainer insert pulled out) Dimensions Type 1 N/Type 1 NI Specifications subject to chang

Open the catalog to page 2All SAMSON catalogs and technical brochures

-

TROVIS 5590 Web Module

2 Pages

-

Room Controller TROVIS 5572

2 Pages

-

Room Panel TROVIS 5570

2 Pages

-

Line Splitter TROVIS 5486

2 Pages

-

Type 9 Temperature Regulator

6 Pages

-

Type 8 Temperature Regulator

6 Pages

-

Type 5 D Boiler Controller

2 Pages

-

Rotary Plug Valve Type 62.7

7 Pages

-

Actuator Type S

3 Pages

-

Actuator Type MZ

4 Pages

-

Actuator Type MN

3 Pages

-

Actuator Type MD

3 Pages

-

Actuator Type R

3 Pages

-

Actuator Type AT

4 Pages

-

Rotary Plug Valve Type 82.7

7 Pages

-

Rotary Plug Valve Type 73.7

7 Pages

-

Rotary Plug Valve Type 73.3

7 Pages

-

Rotary Plug Valve Type 72.4

7 Pages

-

Rotary Plug Valve Type 72.3

8 Pages

-

SAMSON Positioners

28 Pages

Archived catalogs

-

T21 11

6 Pages