Catalog excerpts

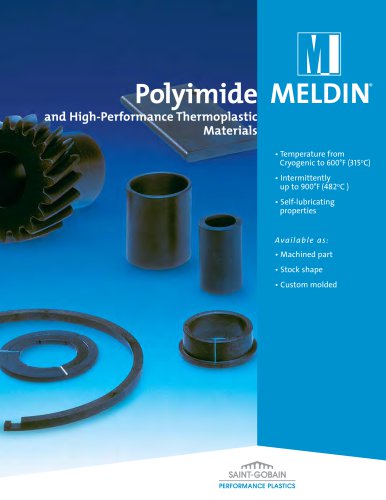

SAINT-GOBAIN SEALS Tolerance Control Meldin® HIGH-PERFORMANCE THERMOSET POLYIMIDE MATERIALS

Open the catalog to page 1

Dimensional Stability at High Temperature Meldin' series materials exhibit extremely high dimensional stability at elevated temperatures. Testing has shown Meldin' materials have less than 0.04% variation from its original dimensions after cycling from 73°F (22.770C) to 500oF (260oC) over a 2-day period. The material is able to withstand thermal shocks very well, adding to the dimensional stability of the material. One particular grade - Meldin' 7022 -exhibits an extremely low coefficient of thermal expansion, resulting in a thermal expansion behavior similar to aluminum. Total Process...

Open the catalog to page 2

Meldin Thermoset Polyimide Materials ® Meldin® 7001, Unfilled Grade Meldin® 7211, Lowest Friction Grade A thermosetting polyimide, Meldin® 7001 is our unfilled base resin. This grade offers the maximum mechanical properties and high chemical resistance. The Meldin® 7001 grade is ideal for electrical and thermal insulating applications. More ductile than ceramics and lighter weight than metals, Meldin® 7001 is a popular choice for structural parts in aerospace and other applications where metal replacement is desirable. The purity of Meldin® 7001 in combination with the above-mentioned...

Open the catalog to page 3

Molding Method Code* DF CM PROPERTY at @ 73°F (23°C) TEST METHOD ENGLISH (METRIC) SPECIFICATION QUALIFICATION ASTM D 6456-99 Standard Specification for Finished Parts Made from Polyimide Resin Satisfies Type I D Type I P AMS SAE 3644G Polyimide, Molded Rod, Bar and Tube, Plaque, and Formed Parts Satisfies Class 1 Form D Class 1 Form P MIL-R-46198 Resin, Polyimide, Hot Pressed or Pressed and Sintered Satisfies Type I D Type I P *Molding Method Codes: Direct Formed (DF), Compression Molded (CM) NOTE: See page 6 for properties of isostatically molded material.

Open the catalog to page 4

Type III Class M Class 5 Form M Type III Class M Type II Class 1M Class 2 Form M Type II Class 1M Type II Class 2M Class 3 Form M Type II Class 2M Type II Class 3M Class 4 Form M Type II Class 3M ASTM Meldin® Meldin® Meldin® Meldin® Meldin® SPECIFICATION QUALIFICATION ASTM D 6456-99 Standard Specification for Finished Satisfies ^ Type 1M Parts Made from Polyimide Resin AMS SAE 3644G Polyimide, Molded Rod, Bar and Tube, Satisfies ^ Class 1 Plaque, and Formed Parts Form M MIL-R-46198 Resin, Polyimide, Hot Pressed or Pressed Satisfies ^ Type 1M NOTE: This data falls within the normal range of...

Open the catalog to page 6

Test Conditions Measure the tensile strength and % elongation of a control sample and then immersing tensile bars in each fluid for 100 hours and 1000 hours. After each time period, the tensile bars were dried and tested to determine if there were any effects of the immersion in common aerospace fluids. Conclusion As seen in the following graphs, Meldin® 7021 shows no ill effects after long term immersion in common aerospace fluids.

Open the catalog to page 7

Applications of Meldin Thermoset Polyimide Materials ® Meldin® 7001 materials are direct formed and machined for use in critical plasma-cutting torches in the torch handle. These torches create high energy vortex gas streams, and Meldin® parts distribute these gases precisely due to their inherent dimensional stability and machinability. Also, other parts in the torch handle insulate high electrical energy from the user, ensuring safe operation. High impact resistance increases the useful life of this equipment as compared to ceramic alternatives. Our Meldin® 7021 self-lubricating polyimide...

Open the catalog to page 8

Many manufacturing lines throughout the industry use sliding surfaces or sliding transport modules. High-temperature sliding surfaces are to be wear-resistant, self-lubricating, not scratching the parts that slide over them and should, in some cases such as glass handling, not cause stresscracking to the material due to too rapid cool-down. Meldin® 7021 and Meldin® 7022 can do all of the above and are the industry's choice for high-temperature sliding applications. G3Meldin® Self-lubricating grades of Meldin® are used as piston rings and thrust washers in transmissions and pumps for...

Open the catalog to page 9

Customized Engineering Support and Solutions Saint-Gobain Seals Sites for Meldin® Thermoset Polyimide Products Saint-Gobain Seals uses its state-of-the-art testing and engineering equipment to support you in your most challenging applications. Tribology Test Rigs Tribology test rigs continuously measure material wear, coefficient of friction, and mating surface temperature over time. A wide range of mating surface materials, surface finishes, and surface hardnesses are available for testing. Test rig options include submerged (wet) testing, as well as externally heated mating surfaces to...

Open the catalog to page 10

Meldin Thermoset Polyimide Critical Parts and Shapes ®

Open the catalog to page 11

A Global Network of Expertise and Service Manufacturing and sales locations Sales only locations Manufacturing and sales locations Sales only locations 7301 Orangewood Ave. Garden Grove, CA USA 92841 Phone: +1-800-544-0080 Av. Independencia, 7031-Jd. Sao Matheus Sao Paulo, Vinhedo, Brazil 13280 Phone: +55 19-2127-8521 Detroit, MI USA Phone (office): +1-248-834-2504 Phone (mobile): +1-248-420-8918 386 Metacom Avenue Bristol, RI USA 02809 Phone: +1-401-253-2000 45-46 Avda Ebro Pol El Sequero 26150 Agoncillo, La Rioja, Spain Phone: +34 941-29-20-53 12941 North Freeway, Suite 226 Houston, TX...

Open the catalog to page 12All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages