Catalog excerpts

SAINT-GOBAIN SEALS Sealing Control OmniSeal® SPRING-ENERGIZED SEALS seals.saint- gobain.com

Open the catalog to page 1

Welcome to the Saint-Gobain Seals World: Experience You Can Rely On ... Time After Time Saint-Gobain has a rich tradition of excellence that dates back more than 350 years. Today, it is among the world’s top 100 industrial corporations and a leader in the development and production of engineered components and materials. In 1665, King Louis XIV signed the letters patent, leading to the creation of Saint-Gobain on an industrial basis. Among the company’s earlier and more notable projects was the manufacturing of 357 mirrors for the Hall of Mirrors in the Palace of Versailles. From these...

Open the catalog to page 2

Saint-Gobain Seals’ global presence allows us to manufacture OmniSeal® spring-energized seals throughout the world, with sites located in Garden Grove, California, USA; Kontich, Belgium; Kolo, Poland; Willich, Germany; Minhang, Shanghai, China; Suwa, Japan and Vinhedo, Brazil. To further support your needs we also have a technical office available in Agrate Brianza, Italy. The majority of our products are custom designed through careful and detailed collaboration with each customer, giving them access to the market-leading engineering, research and customer service expertise of our...

Open the catalog to page 3

Welcome to the Saint-Gobain Seals World A Tour of Our Capabilities When Our Spring-Energized Seals Journey Began Our Spring-Energized Seals and Their Part in History OmniSeal® Elements How Our OmniSeal® Spring-Energized Seals Work Our Seal Jacket Materials Our Investment in Industry-Recognized Material and Qualification Standards Our Spring-Energizer Materials Our OmniSeal® Back-up Rings Seal Function and Motion Friction and Rotary Motion Temperature, Pressure and Extrusion Gap Hardware, Finish and Hardness Gland Design Our Seal Design Variations Markets and Case Studies Oil & Gas Aerospace...

Open the catalog to page 4

When Our Spring-Energized Seals (SES) Journey Began What Is the OmniSeal® Product Line? OmniSeal® seals are the Saint-Gobain Seals product family of spring-energized PTFE seals made from high-performance polymer materials. In the early 1950s, OmniSeal® seals were first developed by three separate entrepreneurs in Southern California, each introducing a unique design: OmniSeal®, TEC Ring and RACO® seals. These seals were developed to provide improved performance over soft elastomeric seals and hard metal gaskets in applications involving cryogenic liquid propellants in various rocket engine...

Open the catalog to page 5

Our Spring-Energized Seals and Their Part in History Hardware that was built for space vehicles in the Apollo moon exploration program contained a variety of OmniSeal® products. The Lunar Lander at the Smithsonian National Air and Space Museum in Washington, D.C., displays our RACO® seal (a design within the OmniSeal® product family), which was used to seal the triangular shaped window on the space vehicle. OmniSeal® seals were designed and used in the first space shuttle launched in 1981 by NASA as part of their STS (Space Transportation System) program. Since that time, our seals have...

Open the catalog to page 6

How Our OmniSeal® Spring-Energized Seals Work The OmniSeal® spring-energized seal is a spring-actuated, pressureassisted sealing device consisting of a PTFE (or other polymer) jacket partially encapsulating a corrosion-resistant metal spring energizer. When the OmniSeal® seal is seated in the gland, the spring is under compression, forcing the jacket lips against the gland walls and thereby creating a leak-tight seal. The spring provides permanent resilience to the seal jacket and compensates for material wear and hardware misalignment or eccentricity. System pressure also assists in...

Open the catalog to page 7

Omni Seal® Our Seal Jacket Materials Saint-Gobain Seals' Fluoroloy® compounds, which make up the seal jackets, are made from high-performance polymer resins that are compounded and processed for optimum performance in a wide variety of sealing environments. The materials listed below are our most commonly recommended compounds and are suitable for most applications. Over the years, Saint-Gobain Seals has developed more than 500 blends for use in unique sealing applications, and we are continually formulating and developing new materials. * Wear Factor: 1 = Excellent, 15,000 = Poor

Open the catalog to page 8

Omni Seal® MATERIAL CODES AND PROPERTIES Material Code * Wear Factor: 1 = Excellent, 15,000 = Poor

Open the catalog to page 9

Our Seal Jacket MaterialsMATERIAL CODES AND PROPERTIES Material Code * Wear Factor: 1 = Excellent, 15,000 = Poor

Open the catalog to page 10

Our Investment in Industry-Recognized Material and Qualification Standards Material Properties and Qualifications The demand for additional qualifications has been increasing over time due to stringent environmental requirements. Saint-Gobain Seals’ Research and Development department has been continuously working on the development of new materials and qualifications in order to meet the new industry standards of tomorrow. This has resulted in our materials being qualified according to international standards applicable for different industries, several of which are detailed below. For...

Open the catalog to page 11

Our Investment in Industry-Recognized Material and Qualification Standards Material Compliance and Regulations for the Life Sciences Industry From material selection to clean room operations, Saint-Gobain Seals offers the technology and infrastructure to support today's life sciences customer. Our extensive material catalogue includes different materials such as PTFE, PEEK, PCTFE, UHMW-PE and PFA based compounds that are compliant with one or more life sciences regulations. Please refer to the table below. All listed FDA compliant Fluoroloy® materials are approved for repeated contact with...

Open the catalog to page 12

Omni Seal® The metallic spring energizers available with OmniSeal® seals are listed in the chart below. Because of the nearly infinite variety of fluid media that may be encountered by the seals, no specific recommendations are made. The various stainless steels listed are compatible with most fluids. For questions or more information about media compatibility, please contact our Technical Support team at sealsmarketing@saint-gobain.com or refer to the back page for site contact information. Optional Energizers OmniSeal® 103A seals may be ordered with optional elastomeric O-ring energizers...

Open the catalog to page 13All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

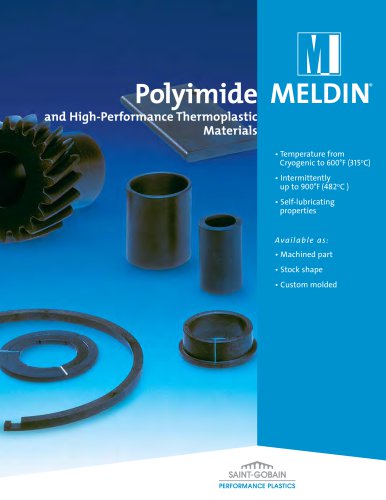

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages