Catalog excerpts

High Performance Fluoropolymer Materials RULON Shaping the Future o f Industr y Through Per formanc e Plastics • Low Fric tio n • High Wear L i fe • Chemical Re s i s t a n ce • Low Mainte n a n ce

Open the catalog to page 1

Saint-Gobain Saint-Gobain is a worldwide group whose history spans more than three centuries. Created in 1665 in France, Saint-Gobain launched its first industrial department with the production of mirrors, which adorn the famous Hall of Mirrors at Versailles. Expansion beyond French borders began in the middle of the 19th century. An international pioneer, Saint-Gobain established a glass factory in Germany in 1857, another in Italy in 1889 and one in Belgium in 1904. The group moved toward the New World in 1937 with the opening of a plant in Brazil. Early Diversification Strongly...

Open the catalog to page 2

Products Bearings: Sleeve, flanged, and thrust bearings are available in the standard materials, Rulon® LR, J, and 641, through our distribution channels. Please contact Saint-Gobain Performance Plastics customer service for the preferred distributor in your area, or for other material options. Materials Selection Guide . . . . 3 Solid and split piston rings, featuring a full complement of joint configurations, can be manufactured to your custom specifications, or our applications engineers can work with you to design the optimal ring for your needs. Please contact the main number and you...

Open the catalog to page 3

Rulon® Grades Materials Selection Guide Grade Color Maroon Maroon Gold Max Load "P" (psi) MPa Max Speed "V" (fpm) m/s Max "PV" (psi-fpm) (MPa • m/s) Mating Surface Painted metal Steel & Stainless Steel resistance Insulative prop. (Elec & Temp) Ou r St an hig dard R her ulo phy n® sica sea Ou l pr l ma r St ope ter Hig an rtie ial w h C dar s th ith ree d R an p a ulo LR nd n® Ab bea ras Low ion ring g Rul es res rad on t Co ®s ista e. erie effici nce s. E ent xce of F Wi llen rict del t in ion yu sul of sed ato in t r. he foo dp r Ver ind ocess yg ust ood ry. ope ra env tion Go od iron in w...

Open the catalog to page 4

Rulon® AR is a light maroon colored material best known as the current version of the first Rulon® introduced, namely Rulon® A. It is somewhat more flexible than Rulon® LR, hence suitable for seals and bonded coating of slide surfaces. It has many decades of use in automotive shaft seals and fuel metering pump cups. Rulon® AR has a practically universal chemical inertness like that of Rulon® LR and provides long life and reliabiltiy in continuous non-lubricated service. It is capable of operating at PV values up to approximately 10,000. Higher PV values are possible for intermittent use...

Open the catalog to page 5

Rulon® LR is a maroon colored bearing material best known for its versatile design properties. It is compatible with most hardened steel substrates. Mild steel is acceptable; harder running surfaces are better. Rulon® LR has a practically universal chemical inertness. Of the chemicals encountered in commercial practice, only molten sodium and fluorine, at elevated temperatures and pressures, show any signs of attack. For continuous non-lubricated service, Rulon® LR sleeve bearings are capable of operating up to 10,000 PV. Higher values are possible for intermittent service. Design Criteria...

Open the catalog to page 6

Rulon® J is an all-polymeric reinforced, dull gold colored PTFE compound that operates exceptionally well against soft mating surfaces such as 316 stainless steel, aluminum, mild steel, brass and other plastics. The unique "shaft friendly" material is also low in friction and wear and self-lubricating. Rulon® J has one of the lowest coefficients of friction of most reinforced PTFE materials. This makes it ideally suited for start/stop applications where stick-slip must be eliminated. The tribological properties of this material also make it suitable for both bearing and wear component...

Open the catalog to page 7

Rulon® 641 is manufactured from FDA compliant (Reference Master File #MAF-288) materials which possess excellent load and wear characteristics. It offers excellent, continuous non-lubricated service up to 10,000 PV – higher for intermittent service. While the load capacity of Rulon® 641 is generally limited to 1,000 psi (6.9 MPa) at room temperature, deformation is a function of wall thickness, temperature and load. Its compatibility with a wide array of mating surfaces, including mild steel, 303 and 316 stainless steels, as well as harder materials, make it a good choice for most food and...

Open the catalog to page 8

Rulon® W2 is a black PTFE-based material developed for use in fresh-water applications. It exhibits low friction and excellent wear characteristics (one of the lowest wear rates in fresh water) as well as good thermal dissipation, preventing shaft distress. Its properties are enhanced when wet. It is compatible with most metal substrates and soft mating surfaces. Rulon® W2 is a good alternative to Rulon® J when superior chemical resistance is needed. However, it should not be used on very soft mating surfaces or where electrical insulation is desired. Design Criteria Rulon ® W2 Temperature...

Open the catalog to page 9

Rulon® 123 is a glossy black non-abrasive compound for softer mating surfaces, such as stainless steel. This material has excellent chemical resistance and is FDA, USDA, and NSF compliant. It is less expensive than Rulon® J, but is slightly less flexible and higher in wear. It has a high resistance to deformation, low coefficient of friction and good thermal and electrostatic dissipation. This material has a maximum operating temperature of 550˚F (288˚C). Rulon® 123 releases black wear debris over time and should not be used in ultra-dry, vacuum applications, or where electrical insulation...

Open the catalog to page 10

Rulon® 488 is a dull turquoise material originally developed for use with painted surfaces. It has been used in veneer dryer bearings in the plywood industry. Its excellent wear resistance, especially in extremely dry environments, make it a material of choice in hydrogen and natural gas compressors. Its almost universal chemical resistance enables it to withstand corrosives and acids sometimes present in trace amounts in these environments. It has a higher load capacity than Rulon® J and better abrasion resistance than both Rulon® J and Rulon® 123. Design Criteria Rulon ® 488 Temperature -...

Open the catalog to page 11All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

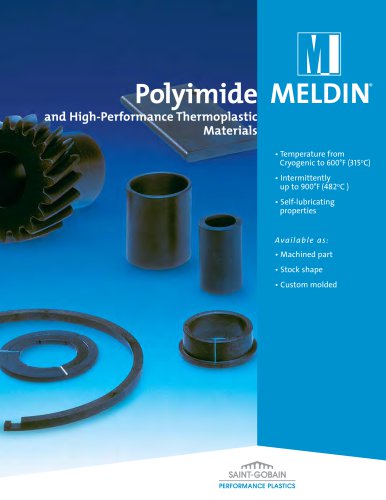

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages