Catalog excerpts

High Performanc bearing materials • Self-lubricating design • Temperature resistant • Dimensionally stable in fluids • Chemically resistant • Flexible material design • Low weight/high strength ratio PERFORMANCE PLASTICS

Open the catalog to page 1

Saint-Go ba in is a worldwide group whose history spans more than three centuries. Created in 1665 in France, Saint-Gobain launched its first industrial Department with the production of mirrors, which adorn the famous Hall of Mirrors at Versailles. Expansion beyond French borders began in the middle of the igth century. An international pioneer, Saint-Gobain established a glass factory in Germany in Belgium in igo4. The group moved toward the New World in ig¡7 with the opening of a plant in Brazil. Early Diversification Strongly established in flat glass production, Saint-Gobain began...

Open the catalog to page 2

Materials Selection Guide 3 Standard Sizing Charts RULON® Standard Metric New Metric RULON® Standard Application Inquiry Form 20

Open the catalog to page 3

Comments RULON® 641 3 1=Low, 5=High Relative Rating Environment Mating Surface Steel & Stainless Steel Performance Rulon® Grades Materials Selection Guide

Open the catalog to page 4

The list above is only a partial list of available formulations of RULON.® PV data may be exceeded based on specific application requirements. Ask to speak to a Saint-Gobain Performance Plastics Application Engineer. RATINGS above are relative within RULON® family ONLY. For RULON® materials, coefficient of friction decreases with increasing load, and wear decreases with increasing surface hardness. For PTFE based materials, wear in steam and wet environments is higher than in dry environments. Saint-Gobain Performance Plastics offers enhanced Rulon grades which minimize this effect. Most...

Open the catalog to page 5

Design Criteria In choosing the appropriate RULON® bearing, the critical parameters of the application must first be determined. Bearing load, speed, PV, environment, mating surface, duty cycle, etc., all play an integral part in this choice.The more important criteria are described here, and their values are listed in the "Material Selection Guide". Bearing Pressure Bearing pressure is measured in pounds per square inch (psi) (MPa). It is calculated by distributing the total load in pounds (N) that the bearing is carrying by the projected area (I.D. x length in inches) (mm) of the bearing....

Open the catalog to page 6

Wear rate: RULON® bearings are self- lubricating because a small quantity of RULON® or PTFE material is transferred to the mating surface during startup. After initial break-in, the wear rate levels out. This phenomenon is why bearing recommended conditions, long bearing life is possible. Contamination, insufficient shaft hardness, coarse shaft finish, corrosion, etc., accelerate wear because the shaft/bearing cannot properly break- in under these conditions {Figure 2). Performance Considerations RULON® materials are capable of operating rates as a function ottime can be greatly affected by...

Open the catalog to page 7

For continuous, non-lubricated service, RULON® LR sleeve bearings are capable of operating at PV values up to approximately Figure 3 shows wear rates as a function ottime at various PV values. RULON® bearings are generally limited to deformation is a function of wall thickness, temperature and load {Figure 4). Because the thickness of the RULON® sleeve affects deformation under load, load limits can be increased by using thin wall bearings or bonding in place. RULON® LR bearings are generally limited to 400 ft/min (2.0 m/s) under dry, low-load operation. Higher speeds are possible with...

Open the catalog to page 8

Bearing Failure At elevated temperatures and heavy load, RULON® LR bearings will not shatter, but will merely deform. This limits sudden breakdowns and possible damage to other components. Corrosion resistance RULON® LR material is practically inert to all acids, bases and solvents. Typical Applications • Dryer oven conveyors • Vacuum metalizing equipment • Photographic processing equipment • Hydraulic actuators • Machine tool ways and gib slides Application Case Story Rulon® LR was selected for this application because of its lubricity and ability to withstand abrasion. The blender is used...

Open the catalog to page 9

RULON® J is an all-polymeric reinforced PTFE compound that operates satisfactorily against soft mating surfaces such as 316 stainless, aluminum, mild steel, and frequently, other plastics.The unique "shaft kindliness" of RULON® J is in addition to the expected attributes of low friction and wear, self-lubrication In fact, RULON® J has the lowest coefficient of friction of any available reinforced PTFE.This makes it ideally suited for start/stop applications where stick-slip must be eliminated. RULON® J bearings are designed to be dimensionally interchangeable with RULON® LR bearings and...

Open the catalog to page 10

Bearings confined in the proper housing are only able to grow radially. Typically, one-third of the differential growth (between bearing O.D. and housing) results in compression of the RULON® material, and two-thirds results in close- Standard RULON® LR and RULON® J stock bearings are designed with sufficient clearance to operate between -70°F (-57°C) standard bearing sizes. For ambient additional clearance should be provided. Other design options are available for high temperature service. Contact your local District Sales Manager to seek design assistance. Typical Applications: • Plain...

Open the catalog to page 11

The RULON® 641 bearing overcomes the chronic problems that plague other food and drug contact bearings. For the first time ever, design engineers can have the following features in one non-lubricated bearing: FDA-cleared materials, excellent load and wear characteristics, wide ranging temperature capability and naturally white color. Wear Characteristics RULON® 641 offers excellent, continuous higher. Figure 70 shows wear rates of RULON® 641 as a function ottime at various PV values. For comparison, virgin MPa x m/s) PV is also shown.The mating surface is 316 stainless steel. Mating...

Open the catalog to page 12All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

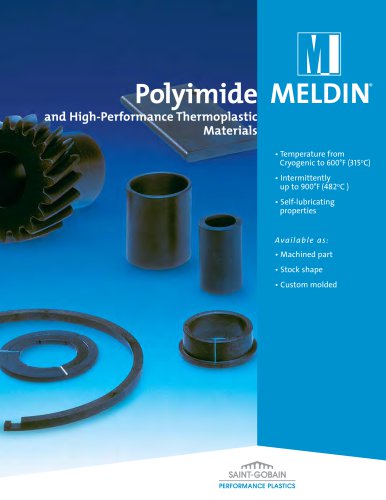

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages