Catalog excerpts

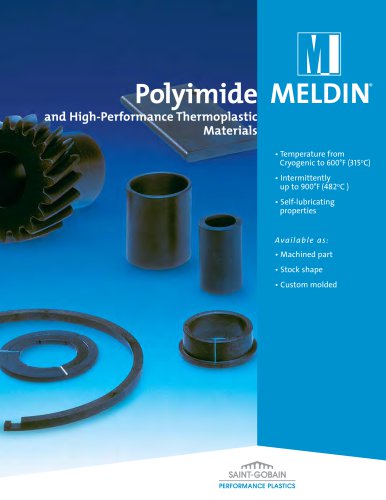

Polyimide MELDIN and High-Performance Thermoplastic Materials • Temperature from Cryogenic to 600°F (3150C) • Intermittently up to 900°F (4820C ) • Self-lubricating properties Ava i l a b l e a s: • Machined part • Stock shape • Custom molded

Open the catalog to page 1

Saint-Gobain Performance Plastics Corporation has built a reputation for innovation through the development of high-performance polymer components, solving the most demanding design problems. Many products are in use today only because our parts have out-performed and replaced metals, ceramics, and inferior plastics in critical applications. The variety of manufacturing processes offered by Saint-Gobain Performance Plastics will provide you with numerous design possibilities and customized engineered solutions. Depend on Saint-Gobain Performance Plastics for materials technology... and...

Open the catalog to page 2

Typical Properties Max. Tensile Strength @RT Max. Flexural Strength @RT Max. Flexural Modulus @RT Max. Compressive Strength @RT Max. Heat Deflection or Use Temp. High Temperature Corrosive Water Steam Manufacturing Process Compression Molding X Injection Molding X X Available Shapes Rods X Sheets X Finished Parts or Near Net Shape X X Machined Parts X X X Design Performance With MELDIN® Materials These materials, available in custom molded and machined components and stock shapes for machining, retain their critical properties over a temperature range from cryogenic through +600ºF (315ºC)...

Open the catalog to page 3

Principal Features of MELDIN 1000 Excellent Chemical Resistance Even at elevated temperatures, most MELDIN® 1000 grades have superior resistance to chemicals ranging from acids to oils and solvents to fuels, and even to high temperature steam. Plus the MELDIN® 1380 grade works well in applications that have food contact. Good Dimensional Stability MELDIN® 1000 materials exhibit low coefficients of thermal expansion, which aid these components when functioning addition, these materials have low creep and low water absorption, which also allows designers to specify close clearances in moving...

Open the catalog to page 4

MELDIN® 1003 components offer the highest level of strength and rigidity for this product family. They maintain high chemical, tensile, and flexural properties even at elevated temperatures. Specify MELDIN® 1277 when the product requirements call for structural integrity also exhibits good electrical insulative properties and dimensional stability. MELDIN® 1357 offers the lowest wear rate and coefficient of friction, which makes it the best candidate for tribological applications. In addition, its self-lubricating properties allow it to operate quietly in dry operating Specify MELDIN® 1380...

Open the catalog to page 5

Compressor Scroll Tip Seals For scroll tip seal applications, MELDIN® 1000 series materials provide some parts with superior wear resistance properties, and superior deformation properties over those of standard PTFE scroll tip seals. Appliance Applications MELDIN® 1000 series components are used in appliance applications due to their superior wear life and ability to operate without the need for any oils or lubricants. In addition, the MELDIN® 1380 grade complies with the FDA Title 21 CFR regulations for contact with articles intended for repeated use in contact with food. Vehicle...

Open the catalog to page 6

Typical Properties of MELDIN 1000 ® TEST METHOD ENGLISH (METRIC) MECHANICAL @ RT Tensile Strength Tensile Modulus Flexural Modulus Flexural Strength Compressive Strength Izod Impact Strength (notched) THERMAL Coefficient of Thermal Expansion Heat Deflection Temperature Thermal Conductivity Surface Resistivity GENERAL Specific Gravity Water Absorption Compressive Strength Compressive Strength

Open the catalog to page 7

Principal Features of MELDIN 2000 ® Excellent Tensile Strength and Elongation MELDIN® 2000 materials exhibit superior tensile strength and elongation properties, even at elevated temperatures, providing the mechanical integrity necessary for the most demanding applications. High Compressive Strength With an ultimate compressive strength of over 40,000 psi and a usable limit of 34,000 psi at 10% strain, MELDIN® 2001 provides the highest resistance to compressive failure of any of the MELDIN® 2000 compositions. The additional formulations, however, also offer excellent compressive properties....

Open the catalog to page 8

This material is best suited for thermal and electrical insulation and radiation resistance. MELDIN® 2001 has the highest compressive properties of any material in the series. The MELDIN® 2030 bearing compound operates with extremely low friction in both dynamic and static applications, and provides thermal and electrical insulation. MELDIN® 2211 offers the balanced properties of low friction, high strength and resistance to compressive creep. Product availability: A multi-purpose bearing grade for high temperature and high load applications, MELDIN® 2021 maintains its strength and rigidity...

Open the catalog to page 9

Glass Handling Equipment In glass bottle production, MELDIN® take-out inserts and grippers are used for mold removal and transfer of red-hot bottles. MELDIN® components improve bottle quality and production yield. Due to their low thermal conductivity, they reduce microcracking caused by rapid, non-uniform cooling. Bearing Applications MELDIN® materials can be used for very demanding bearing applications in motors, general industrial equipment and machinery, and business machines. Welding or Plasma Cutting Equipment Because of their high temperature capabilities, MELDIN® materials improve...

Open the catalog to page 10

Typical Properties of MELDIN 2000 ® TEST METHOD ENGLISH (METRIC) MELDIN® 2001 MELDIN® 2021 MELDIN® 2030 MECHANICAL @ RT Tensile Strength Ultimate Elongation Ultimate Tensile Modulus Flexural Strength Ultimate Flexural Modulus Coefficient of Thermal Expansion Surface Resistivity Water Absorption Outgassing Outgassing Tensile Strength Ultimate Elongation Ultimate Compressive Strength Ultimate Compressive Strain Yield Compressive Modulus ASTM D695 modified ASTM D695 modified Compressive Strength Yield Tensile Modulus OTHER Outgassing Specific Gravity Dielectric Strength ELECTRICAL Volume...

Open the catalog to page 11All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages