Catalog excerpts

Spring Energised Seals >

Open the catalog to page 1

A Worldwide Leader in High Performance Sealin g > OmniSeal ,a recognized name in seal-ing for over fifty years. First as Fluorocarbon then Furon and now as Saint-Gobain Performance Plastics(SGPPL). OmniSeals, have been usedin a multitude of applications where durability, resistance to chemicals and operation at temperature extremes is crucial. Our spring energised seal designs are widely recognized throughout the industry. OmniSeal high-performance spring energised seals reduce friction, operate in harsh environments, reduce downtime and extend equipmentservice life. Compagnie de...

Open the catalog to page 2

Backed by a proud heritage of productinnovation, technological expertise and market leadership, Saint-Gobain Performance Plastics is dedicated to working with our customers to solve todays tough seal application issues and the challenges that lie ahead.OmniSeal seals are manufacturedthroughout the world, with sites located in North America and South America, Europe and Asia.The seals were originally designed anddeveloped in Southern California. The current facilities located in Garden Grove, California, Kontich in Belgium and SuwaJapan design and manufacture HighPerformance Spring Energised...

Open the catalog to page 4

The OmniSeal is a spring actuated, pressure assisted sealing device con- sisting of a PTFE (or other polymer) jacket, partially encapsulating a corro-sion resistant metal spring energiser.When the OmniSeal is seated inthe gland, the spring is under compression, forcing the jacket lips against the gland walls thereby creating a leak-tight seal. The spring provides permanentresilience to the seal jacket and compensates for material wear and hardware misalignment or eccentrici- ty. System pressure also assists in energizing the seal jacket. Spring loading, assisted by system pressure provides...

Open the catalog to page 6

Radial Sealsin Static Service > While most of the OmniSeal designscan be used as static radial seals, the OmniSeal 103A, Page 16, is generally recommended for this service. Its moderate to high spring load provides positive sealing under most static sealing conditions. Radial Sealsin Reciprocating Motion > Reciprocating radial seals are themost common OmniSeal applica- tions. For rod and piston sealing and similar applications, the OmniSeal400A, Page 18, is recommended for general purpose sealing at low tomoderate pressures. This series has alow load, high deflection spring which provides...

Open the catalog to page 7

RACO 1100A is also an excellent choice when maximum sealability is mandatory in liquids and gases with a low specific gravity and sealing atcryogenic temperatures. The OmniSeal 103A, face seal is generally the first choice for most static face seal applications. This series utilizes a moderate to high load spring, and is capable of sealing effectively over a wide temperature and pressure range.Because of its very high springloading, the OmniSeal RACO OmniSeal 400A, is recommended forrotary face seal applications at slow to moderate rotary speeds. Low spring loading keeps friction to a...

Open the catalog to page 8

OmniSeal APSOmniSeal 400 A OmniSeal RPII OmniSeal 103A OmniSeal 1100A Average Spring Load - N/mm of Seal Circumference > Note: The values above are for standard spring materials and thicknesses. Other materials and spring thicknesses may be substituted;consult factory for availability. > 211815129 6 300 4 8 1/4 (5)3/16 (4)1/8 (3) 3/32 (2)1/16 (1) Pressure - MPa 1,501,25 1,00 0,75 0,50 0,2500 2,5 5,0 MPa C O N S U L T F A C T O R Y Normal Cross Sections Pressure Load - N/mmCircumference Surface Speedm/s F= Total loadN/mm circumference(pressure load + spring load)D= Diameter of dynamic...

Open the catalog to page 9

(OmniSeal 103AShown forIllustration Only) Temperature - C -100Ћ 0 100ڋ 200ڋ 300ڋ Seal Design Vs. Temp. Chart. Temperature Vs. Pressure and Seal Design > * For temp. below -20ڰC consult factory

Open the catalog to page 10

Back-Up Rings are used when sealingfluids or gases at high temperature and high pressure combinations. Careful attention is also required at high pressure and high speed reciprocation conditions. If the application parameters fall outside the limits set in the tables on page 10, we strongly advice to contact our technical support for further assistance. Extrusion is a function off a) the size of the extrusion gap b) the temperature c) the system pressure d) surface speed (reciprocating movements) Under pressure the PTFE tends to flow into the extrusion gap. Dynamicreciprocating movements...

Open the catalog to page 12

Saint-Gobain Performance Plastics offersthe industrys most complete line of spring energiser configurations. OmniSeal103A Spring Design OmniSeal 400A Spring Design OmniSeal APS Spring Design OmniSeal RPII Spring Design OmniSealRACO 1100A Spring Design > All OmniSeal designsexcept OmniSeal RPIIcan be supplied with a sharp edge on either the I.D. or O.D. sealing lip. This edge provides a scraper/wiperaction for sealing abrasive or viscousmedia. May also be used as an environmental excluder. OmniSeal seals canbe supplied with anextended heel section for improved resistance to extru- sion at...

Open the catalog to page 13

6 Omniseal > 103A Omniseal > ή RP Omniseal > APS Omniseal > ή 400A > Load (N per mm circumference) 0,1 0,2 0,3 0,4 0,5 0,6 0,7 >

Open the catalog to page 16

6 Omniseal > 103A Omniseal > ή RP Omniseal > APS Omniseal > ή 400A > Load (N per mm circumference) 0,1 0,2 0,3 0,4 0,5 0,6 0,7 >

Open the catalog to page 18

6 Omniseal > 103A Omniseal > ή RP Omniseal > APS Omniseal > ή 400A > Load (N per mm circumference) 0,1 0,2 0,3 0,4 0,5 0,6 0,7 >

Open the catalog to page 20

6 Omniseal > 103A Omniseal > ή RP Omniseal > APS Omniseal > ή 400A > Load (N per mm circumference) 0,1 0,2 0,3 0,4 0,5 0,6 0,7 >

Open the catalog to page 22

Inside face sealOutside face seal 26 www.omniseal.com +3234582828 >

Open the catalog to page 26

Design Capabilities > For more than 30 years SGPPL hasdedicated its engineering efforts to solving difficult and unique sealing problems. With each challenge we gained greater insight into the science of specialized sealing.Today, aided by advanced 3-Dmodeling software and the latest visualizing innovations, our teamof skilled design engineers isexploring the next generation of sealing applications. Utilization ofFinite Element Analysis (FEA) as a viable design and production tool facilitates higher productivity,design confidence, reduction in test-ing time and resultant cost savings....

Open the catalog to page 28All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

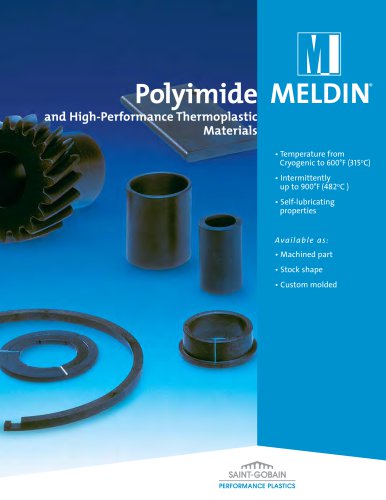

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages