Catalog excerpts

Seal Selection Guide Application Service Ratings OmniSeal Design Profiles Seal Selection Guide Seal Designs Rod/Shaft Piston Face Rod/Shaft Piston Face Poor Static Rod Seals .185 - 60+ Piston Seals .297 - 60+ Rod Seals .185 - 60+ Piston Seals .297 - 60+ Rod Seals .185 - 60+ Piston Seals .297 - 60+ Rod Seals .185 - 60+ Piston Seals .297 - 60+ Rod Seals .076 - 60+ Piston Seals .190 - 60+ Rod Seals .108 - .873 Piston Seals .221 - 1.116 Rod Seals .032 - 16.000 Piston Seals .094 - 16.000 Rod Seals .250 - 60 Piston Seals .427 - 60 Rod/Shaft Piston Rod/Shaft Piston Diameters Min-Max (inches) Spring Materials Standard Cross Sections (inch nom) Standard Gland Sizes Friction Rating General purpose design for most applications. Best suited for dynamic rod and piston seals when pressure is under 3000 psi. Scraper designs can be used as wiper seals or in abrasive medias. Silicone filled spring cavities are available for food process and clean in place applications. Best suited for dynamic rod and piston seals when pressure is under 6000 psi/or when hardware extrusion gaps combined with high temperature are present. The extra material helps prevent seal failure by filling in the extrusion gap similar to a back up ring. Best suited for dynamic rod and piston seals when pressure exceeds 6000 psi and excessive hardware extrusion gaps with high temperatures are present. A high modulus material like Fluoroloy A22 is recommended for the back up ring to reduce the gap and prevent seal extrusion. Designed for rotary shaft applications at less than 500 SFPM. The flange is an anti-rotation device when locked into the mating hardware. Also used as a cryogenic seal in applications such as quick disconnect couplings used in liquid oxygen and nitrogen. The flange prevents shrinkage. Industrial Military Series 400A Flanged Rod/Shaft Piston Face Flanged Standard = 3,000 Flanged = 3,000 Extended = 6,000 Back-Up = 10,000 Rod/Shaft Piston Flanged Standard = 3,000 Flanged = 3,000 Extended = 6,000 Back-Up = 10,000 Rod/Shaft Piston Face Flanged Rod/Shaft Piston Flanged Standard = 3,000 Flanged = 3,000 Extended = 6,000 Back-Up = 10,000 Moderate High Similar in design to the 400A listed above and intended for high volume, less critical applications. Available in fixed cross section sizes for diameters less than 1". Only available with 301 or 316 stainless steel springs. Custom sizes are available with a nominal set up cost. The near constant spring force Advanced Pitch Spring design is best suited for applications where consistent friction is important. Best when used for small diameters in rotary and reciprocating rod and piston applications at temps under 475o F (246o C) Optional spring loads available. Flexible overlapped spring designed for use in static slow dynamic applications when excessive hardware tolerances exist. Spring design affords maximum spring deflection. Recommended for use in viscous applications, such as injection molding and liquid filling equipment. High load spring designed for static internal and external pressure face seal applications. Excellent sealing in light gasses, vacuum and cryogenics. Also used in slow dynamic face seal applications such as swivels joints and marine loading arms. Standard = 3,000 Flanged = 3,000 Extended = 6,000 Back-Up = 10,000 Standard = 3,000 Extended = 6,000 Back-Up = 10,000 Generally used for static applications when positive sealing is most critical. Best suited for use in sealing light gases and vacuum. Can be used in slow dynamic situations when friction is less of a concern. Also used as a cryogenic seal in applications such as quick disconnect couplings used in liquid oxygen and nitrogen. Page Locator Recommended Applications ** *Consult factory **Special cross-sections seals up to 1” are available

Open the catalog to page 1All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

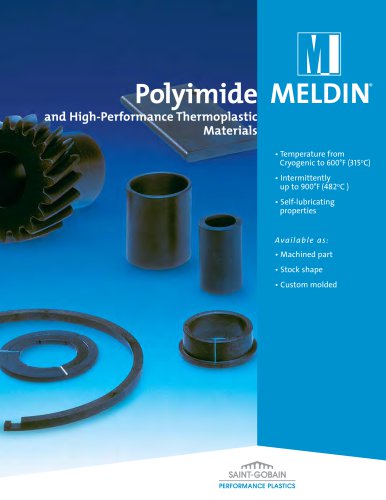

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages