Catalog excerpts

OmniLip ™ rotary shaft seals

Open the catalog to page 1

Table of Contents Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Seal Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Materials/How To Order Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 OmniLip™ Seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 DynaLip®...

Open the catalog to page 2

Saint-Gobain Performance Plastics' Polytetrafluoroethylene "PTFE" Lip Seal, or OmniLip™, was introduced in the early 1970's. The seals were designed to bridge the gap between conventional elastomer hp seals and mechanical face seals. Hostile environments such as extreme temperatures, aggressive media, high surface speeds, high pressures, and lack of lubrication previously forced the designer to specify the expensive and complicated mechanical face seals. Our OmniLip™ seal provides the designer with a significant improvement in performance over elastomer lip seals at a much lower cost than...

Open the catalog to page 3

OmniLip™ and DynaLip® Nomenclature OmniLip™ Seal 1. 2. 3. 4. 5. 6. 7. 8. Outer case* Inner case* Washer* Extension spring (Stainless steel 302) Primary element* Secondary element* Dust excluder* Gasket (FKM) 12 11 10 9 DynaLip® Seal 09. 10. 11. 12. Metal support ring* Extension spring (Stainless steel 302) Seal material* O-Ring (FKM) *See page 3 for material selection Saint-Gobain Performance Plastics 2 +32 (3) 4582828 www.OmniLip.com

Open the catalog to page 4

Saint-Gobain Performance Plastics proprietary seal materials are compounded and processed for optimum seal performance in a wide variety of sealing environments. The materials listed below are the most commonly recommended compounds and are suitable for most applications. These are all low friction materials which have substantially higher PV ratings (Pressure x Velocity) than elastomer materials. Estimated torque requirements or wear life data is not provided since all application variables must be considered before making such calculations. If an estimate on seal life is desired, or if...

Open the catalog to page 5

Seal Type Seal Type Application Details Series 10 and 11 are economical OmniLip™ seal designs employed in a wide range of applications. They are used in lubricated and non-lubricated emdronments. They can be used at shaft speeds to 25 m/s in lubricated media and pressures to 0,7 MPa. Typical applications are: gear boxes and environmental seals. Series 20 and 21 are modifications of Series 10 and 11 which offer longer life and improved sealing of gasses and abrasive media due to their higher lip load. They also offer additional runout capability. They can operate at speeds, pressure and PV...

Open the catalog to page 6

DynaLip® provides similar performance to the OmniLip™ seal but is more economical in smaller quantities. Because the seal has a soft surface on the OD, the seal will not damage the housing and can easily be installed and removed. Due to the seal's soft sealing on the OD, it is recommended that the seal be retained in the gland as shown on page 9. DynaLip® designed for extreme temperatures utilize a metallic support ring to minimize temperature's effect on the seal. The DynaLip® seal selection chart below provides a guide on whether this metallic support is required. Application Details...

Open the catalog to page 7

Gland Dimensions The shaft and bore diameters are based on the standard DIN 3760. Saint-Gobain Performance Plastics can manufacture non-standard sizes also. Contact the Saint-Gobain Performance Plastics Sealing Technology Center at +32 (3) 4582828. Saint-Gobain Performance Plastics

Open the catalog to page 8

( Media Pressure in MPa X Surface Velocity in m/s) The PV value of a compound is the product of the unit load P (MPa) on the projected area and the surface velocity V (m/s). Intermittent service, reciprocating motion, cooling and design innovations permit PTFE compounds to operate at much higher PV values than the limit established using continuous rotary motion. The max PV or limiting PV is reached when the temperature generated by As stated before, cooling and lowering the coefficient of friction by means of lubrication can increase the limiting PV. Since so many application parameters...

Open the catalog to page 9

Hardware Design SHAFT MATERIAL & HARDNESS • Cast iron or hardenable steel is preferred. • Shaft hardness of 40 to 58 HRC is recommended for low to moderate hydraulic oil pressure (0-1,5 MPa). A higher hardness range of 58 to 65 HRC for high pressure hydraulic oil, abrasive or non-lubricating medias, or high speed applications 15 m/s and above. BORE MATERIAL • Cast iron, steel, aluminum and other commonly used metallic and nonmetallic materials are acceptable. Plastics are only acceptable for Dynalip® seals. SHAFT SURFACE ROUGHNESS • The seal contact surface of a plunge ground shaft should...

Open the catalog to page 10

Hardware Variations • OmniLip™ seals incorporating two sealing lips, or a dust excluder, may have seal lip extensions as shown. This must be considered when designing a seal gland. . RETAINER PLATE Non-Standard Seal Configurations STAINLESS STEEL. BPftAG ENERGIZED CHEMICAL PAÜTECDÚN Saint-Gobain Performance Plastics

Open the catalog to page 11

Seal Installation Care must be taken not to damage the sealing lip during contact the kciorY- We can helP with the desi8n and manu" the installation of the shaft through the seal. It is much facture of simPle toolin8t0 assure that the seal is installed easier to install the seal if the shaft enters the seal from without dama8e- OmniLip™ seals and DynaLip8 seals the atmosphere side. If this is not possible, or if the seal must should be Pressed int0 the bore evenlY- A tool> as shown be installed on a shaft which has a keyway or splines, please below, simplifies this operation. Installation...

Open the catalog to page 12

Application Data Form for OmniLip™ and DynaLip® Seals Fax this form to Saint-Gobain Performance Plastics Sealing Technology Center at +32 (3) 4582669 Company Name Individual name Street Address Title City Phone number Zip code State E-Mail Fax number Project Name Application Information and Conditions Device to be sealed ____________________________________________________________________________________ Number of units/year __________________________ Type of motion: □ □ Rotary Number of seals/unit ________________________________ □ Oscillating □ Reciprocating Static Media/Fluid...

Open the catalog to page 13All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

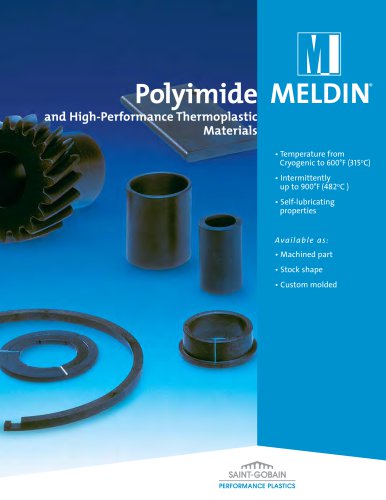

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages