Catalog excerpts

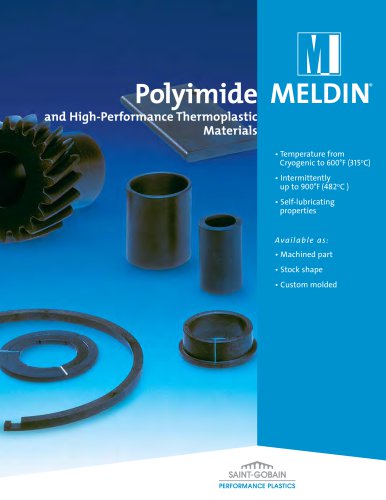

SAINT-GOBAIN SEALS Meldin Meldin® Tolerance Control HIGH-PERFORMANCE THERMOPLASTIC MATERIALS Critical parts making THE difference WZQBvdXuXuI7

Open the catalog to page 1

Welcome to the Saint- Gobain Seals and Poly mers World: Ex per ience You Can Rely O n… Time Af ter Time Saint-Gobain has a rich tradition of excellence that dates back nearly 350 years. Today, it is one of the world’s top 100 industrial corporations and a leader in the development and production of engineered components and materials. In 1665, Louis XIV signed the letters patent, leading to the creation of the SaintGobain Group on an industrial basis. One of the earlier and more notable projects was manufacturing the 357 mirrors for the Hall of Mirrors in the Palace of Versailles. From...

Open the catalog to page 2

Research, custom design and state-of-the-art testing are at the heart of Meldin® solutions. Deep collaboration with each customer, together with our expertise in engineering and customer service, help us deliver in the most demanding applications. Starting with custom blending, mold design, specialized processing and prototyping, all the way to maintaining extremely tight tolerances and meeting stringent quality requirements, we have your needs covered. Our extensive experience of more than 50 years, together with the most modern manufacturing optimization techniques such as WCM, 5S, Kaizen...

Open the catalog to page 3

Welcome to the Saint-Gobain Seals and Polymers World 2 A Tour of Our Capabilities 3 The Importance of Meldin® Thermoplastic 5 Material in Today's World How Our Meldin® Family Started and Evolved 6 Introducing the Key Members of Our Meldin® Family 7 A Snapshot of Meldin® 1000 Series 8 A Snapshot of Meldin® 4000 Series 10 A Snapshot of Meldin® 5000 Series 12 A More Complete Technical Picture 14 of Our Meldin® 5000 Grades Compatible or Not? Meldin® Material's Broad 16 Relationship with Chemicals Meldin® Material's Tribological Performance 18 Automotive Market: How Our Thermoplastic 20 Material...

Open the catalog to page 4

T he Impor tance of Meldin ® T her mopla st ic Mater ial in Tod ay ’s World High-performance polymers have proven to play a key role in our modern life, substantially contributing to the quality, comfort, safety and health of our global society. Linked to innovation and technology, these high-performance plastics are essential for advancing sustainable economic growth in the automotive, aerospace, energy and other industries. Polymers in the Saint-Gobain Seals Meldin® thermoplastic material product line are positioned in the upper section of the polymer pyramid as shown below, representing...

Open the catalog to page 5

How O ur Meldin ® Fami ly Star ted and Evolved Historically, Saint-Gobain Seals (formerly Dixon Industries Corp.) focused on the production of fluoropolymer compounds. Beginning in 1957, our wellknown Rulon® product line was used in a new plastic saddle design and was quickly adapted for wider use. In the 1970s, we developed the Meldin® 2000 product line (based on thermoset polyimide) primarily as a filler for Rulon®. We launched the Meldin® family of thermoplastic products in 1980, starting with the Meldin® 1000 and 5000 series. The Meldin® 4000 series was added in 2014 after the...

Open the catalog to page 6

The Meldin® product line includes our popular 1000, 4000 and 5000 series, which have been developed to satisfy working conditions for applications where metals and other materials may not be adequate: > Meldin® 1000 materials are proprietary polyphenylene sulfide (PPS) based thermoplastic compounds engineered to withstand harsh chemical, environment and temperature conditions. > Meldin® 4000 materials are based on polyamide-imide (PAI) to provide superior mechanical properties at very high temperatures (up to 275°C). > Meldin® 5000 materials are based on polyaryletherketone (PAEK) and its...

Open the catalog to page 7

Meldin® 1000 series is a Saint-Gobain Seals product line based on PPS compounds. Components made of Meldin® 1000 series materials exhibit excellent chemical and thermal resistance, have good dimensional stability and maintain structural integrity, providing design versatility. All grades are processed by injection molding and available as finished parts. The different grade number references a different composition resulting in different properties. Few stock shapes are available, mainly to support prototyping activity. Features/Benefits › Superior resistance to chemicals ranging from acids...

Open the catalog to page 8

This grade offers the highest level of strength and rigidity of the Meldin" 1000 series. It has a very low coefficient of friction and maintains high chemical resistance. It is typically used for thin parts such as piston rings or scroll tip seals. This grade offers the lowest wear rate and coefficient of friction, making it the best candidate for tribological applications. In addition, its self-lubricating properties allow it to operate quietly even in dry environments. This is a bearing grade, internally lubricated according to our latest technology. It is also electrically conductive....

Open the catalog to page 9

Meldin® 4000 is Saint Gobain Seals’ product line of PAI (polyamide-imide) based compounds. The different numbers within the series refer to the unique composition and different properties of the various compounds. Meldin® 4000 grades are manufactured by injection molding with a very limited number of shapes available for prototyping activity. All 4000 series compounds have common properties that make them suitable replacements for metal components: they are stiff and retain high mechanical strength at elevated temperatures; they are very durable even in harsh applications in regards to...

Open the catalog to page 10

Meldin® 4000 Series — Izod Impact Strength Meldin* 4310 This grade is used mainly for washers when needed to minimize the coefficient of friction. Meldin* 4310 Wear grade used mostly for seal rings but also for washers and bearings. Meldin* 4320 Wear grade mainly used for washers when wear reduction and extended lifetime of the component are key. Impact Strength (J/m) Izod Impact Strength — Unnotched 23°C ^ Izod Impact Strength — Notched 23°C This grade provides a very high mechanical and fatigue strength and is suitable for high precision bearings. It has the lowest coefficient of thermal...

Open the catalog to page 11All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

Meldin® Thermoset

12 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages