Catalog excerpts

Design Guide

Open the catalog to page 1

Saint-Gobain Performance Plastics www.rulon-meldin.com

Open the catalog to page 2

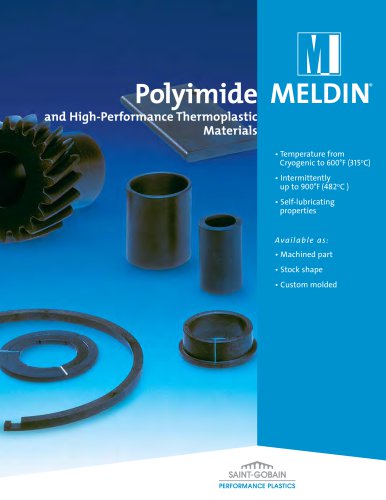

Meldin 7000 SERIES Design Guide ® With more than fifty years of engineered plastics technology and extensive fabrication expertise, Saint-Gobain Polymer Products is recognized the world over as a leader in the high performance polymer components business. The materials and customized components we supply our customers are designed to withstand the harshest environments and perform under the toughest operating conditions. As a result, design engineers trust Saint-Gobain Polymer Products to provide practical, affordable solutions to the most demanding high temperature applications. The Meldin...

Open the catalog to page 3

Meldin 7000 SERIES Design Guide ® Evident in all the Meldin® 7000 series products is Saint-Gobain Polymer Products’ unwavering commitment to quality and service to our customers. Our manufacturing plants have been certified to such worldwide quality standards as: > AS EN9100 > ISO-9001 Production batches of Meldin 7000 resin are tested to a number of ASTM test methods to ensure the performance characteristics meet the requirements and expectations of the most demanding customers in every industry and market we serve. Finished parts made from Meldin 7000 series are also qualified to such...

Open the catalog to page 4

Section one MECHANICAL PROPERTIES VS. TEMPERaTURE Figures 1 through 6 show these linear changes in tensile strength, flexural strength, and flexural modulus for machined, isostatically molded shapes and for direct formed parts made from Meldin 7000 series materials. The Meldin 7000 series materials can operate very well at continuous operating temperatures of 315˚C (600˚F). The Meldin 7000 series materials can also operate intermittently at temperatures up to 482˚C (900˚F). NOTE: The Meldin 7000 series materials cannot operate at the 482˚C temperature continuously – only for short periods...

Open the catalog to page 5

Figure 3 Meldin 7000 Polyimide Shapes Typical Flexural Modulus vs Temperature ASTM D790 Meldin 7001 Meldin 7021 Meldin 7211 Meldin 7022 Figure 5 Direct Formed Meldin 7000 Polyimide Typical Flexural Modulus vs Temperature ASTM D790 Figure 4 Meldin 7000 Polyimide Shapes Typical Flexural Strength vs Temperature ASTM D790 Figure 6 Direct Formed Meldin 7000 Polyimide Typical Flexural Strength vs Temperature ASTM D790 1-2 Saint-Gobain Performance Plastics www.rulon-meldin.com

Open the catalog to page 6

Section one Flexural Strength vs. Temperature Stress-strain information Figures 7 and 8 show the typical stress-strain behavior of the various Meldin 7000 products for ambient (23°C or 73°F) and high temperature (260°C or 500°F) conditions, respectively. As can be seen from these graphs, none of the Meldin 7000 series products have a transition point from elastic to plastic deformation. That is to say, when a tensile force is applied to a Meldin product, the material will essentially deform elastically until it suddenly breaks without having a plastic deformation zone as one would typically...

Open the catalog to page 7

Section ONE direct formed Stress-strain Figure 9 Direct Formed Meldin 7000 Polyimide Typical Stress-Strain in Tension @ 23°C ASTM E8 Figure 10 Direct Formed Meldin 7000 Polyimide Typical Stress-Strain in Tension @ 260°C ASTM E8 Figures 9 and 10 show the same stress-strain properties as the previous two figures, except these values are measured perpendicular to the main forming direction. Generally, the observed values for maximum stress are slightly lower in this case since the material properties are known to be weaker in the perpendicular direction. All remarks related to the differences...

Open the catalog to page 8

Section one linear thermal expansion Figure 11 Meldin 7000 Polyimide Shapes Stress-Strain in Compression @ 23°C ASTM D695 The coefficient of linear thermal expansion over the temperature range of 23°C to 300°C (73°F to 572°F) is shown in Figure 13. To calculate the coefficient over any other temperature range using these curves, simply divide the percent dimensional change over the desired range by 100 x the temperature differential in degrees (ΔT). Figure 13 Meldin 7000 Polyimide Shapes Linear Thermal Expansion ASTM D696 Dimensional Change (%) Figure 12 Meldin 7000 Polyimide Shapes...

Open the catalog to page 9

Section one Typical Properties of Meldin® 7001 and 7021 PROPERTY at @ 73˚F (23˚C) TEST METHOD Molding Method Code* ENGLISH (METRIC) MECHANICAL Tensile Strength Flexural Strength Flexural Modulus Compressive Stress @ 1% Strain Compressive Stress @ 10% Strain Compressive Modulus ELECTRICAL Dielectric Strength, Short time 2mm (.08") thick Surface Resistivity OTHER Specific Gravity Water Absorption, 24 hours Water Absorption, 48 hours Deformation under Load @ 2000 psi Limiting Oxygen Index High Temperature Dimensional Stability @ 500˚F MECHANICAL PROPERTIES @ 500ºF (260ºC) Tensile Strength...

Open the catalog to page 10

Section one Typical Properties of Meldin® 7022 , 7211 and 7003 PROPERTY at @ 73˚F (23˚C) MECHANICAL TEST METHOD Molding Method Code* ENGLISH (METRIC) Tensile Strength Flexural Strength Flexural Modulus Compressive Stress @ 1% Strain Compressive Stress @ 10% Strain Compressive Modulus Coefficient of Thermal Expansion 73 to 500ºF (23 to 260ºC) Thermal Conductivity Dielectric Strength, Short time 2mm (.08") thick Surface Resistivity Specific Gravity Water Absorption, 24 hours Water Absorption, 48 hours Deformation under Load @ 2000 psi Limiting Oxygen Index Tensile Strength High Temperature...

Open the catalog to page 11

Section ONE Typical Properties of Isostatically Molded Meldin® 7000 PROPERTY MECHANICAL ASTM Method Units psi (MPa) Tensile Strength Flexural Strength Flexural Modulus Compressive Stress @ 1% Strain Compressive Stress @ 10% Strain Compressive Stress @ 0.1% Offset Compressive Modulus Thermal Expansion ELECTRICAL Dielectric Strength OTHER Specific Gravity Water Absorption, 24 Hours ASTM D 6456-99 Standard Specification for Finished Satisfies Type 1M Parts Made from Polyimide Resin Satisfies Plaque, and Formed Parts Satisfies Type 1M and Sintered SPECIFICATION QUALIFICATION AMS SAE 3644G...

Open the catalog to page 12All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

OmniLip? PTFE Rotary Shaft Seals

32 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages