Catalog excerpts

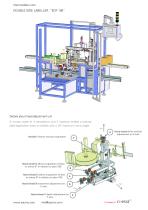

Intermediate units Machine allows exact positioning of labels on both sides of bottles. Bottles arrive directly or on pucks onto a conveyor. A position adjuster centers bottles before labelling. Labels are applied by two plates and finally stuck by foam rubber rollers. Design features Herma 400 labelling heads 5-way head adjustment unit Settings fitted with counters Infeed and spacing screw SIEMENS PLC and display Electrical supply: 400 V, 50 Hz + Neutral Absorbed power: 1,5 KW Electrical cabinet integrated in machine frame Label detection sensor Defective product ejection system Production speed: 80 units per minute • Other brands of labelling heads, PLC or display available on request • Camera for batch number control • Automatic synchronization of labelling and conveyor speeds • Hot foil or thermal transfer coder • Reel support on HERMA head with PLC control system and automatic speed synchronization (for large rollers) GROUP A Company of coesia

Open the catalog to page 1

Details about head adjustment unit 5 moves made of 3 translations and 2 rotations enable a precise label application even on bottles with a 16° maximum conic angle. Hand-wheel E allows angulation of plus or minus 8° in relation to plan Y0Z Hand-wheel B transverse adjustment on b depth adjustment on c Y axis

Open the catalog to page 2All SACMO catalogs and technical brochures

-

ROTARY TABLE

2 Pages

-

Semi-automatic Casepacker

2 Pages

-

Screw capping unit

2 Pages