Catalog excerpts

As an automatic rotating indexed machine, our coding machine is designed for printing on sides or bottoms of products. Products arrive in direct or in pucks on a chain conveyor. Batch number is printed "on the fly" by an inkjet printer or the product is stopped and get marked by a laser. A vision system reads all batch numbers. Design features • DOMINO printer • OMRON PLC and touch screen (for camera and printer) • OMRON camera reads printing, • Vision system based on character recognition (depending on camera installed) • High tolerance scanning according to position and orientation of printing on object (depending on camera installed) Control of number shown on display or calculated (ordinal date code) depending on PLC and camera installed Rejection chute for non-compliant products Low-level lighting controlled by PLC (does not disturb system) Electrical supply: 400 V, 50 Hz + Neutral Absorbed power: 2 kW Independent electrical cabinet mounted on chassis Production speed: 40 to 50 units per minute • Integration of pucks return conveyor • Other brands of PLC, display or marking module available on request • ± 0.02 mm positioning precision Up to 20 writing formats of different sizes and colors can be saved Marking and inspecting can be carried out on 3 lines GROUP A Company of coesia

Open the catalog to page 1

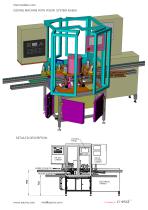

Intermediate units CODING MACHINE WITH VISION SYSTEM MJE50

Open the catalog to page 2All SACMO catalogs and technical brochures

-

ROTARY TABLE

2 Pages

-

Semi-automatic Casepacker

2 Pages

-

Double side labeller EDF 100

2 Pages

-

Screw capping unit

2 Pages