Catalog excerpts

www.ruland.com Oldham coupling: high parallel misalignment capability What to look for in a Servo Coupling Selecting a coupling for a servo application can be a complex process. It involves many different performance factors, including: torque, shaft misalignment, stiffness, rpm, space requirements, and others, that all must be satisfied for the coupling to work properly. Before selecting a coupling, it is helpful to know the specifics of these issues for the application for which the coupling is to be used. Many different types of servo couplings exist with their own individual strong and weak points. This article is designed to introduce end users to the different types of couplings available for servo applications. It also helps the user select the proper coupling for their application by highlighting the factors that should be considered in the decision making process and how they relate to the different product offerings available. Choosing the most appropriate type of coupling to use in servo applications can be confusing. William Hewitson, Director of Manufacturing and Engineering with the Ruland Manufacturing Company in the US, examines the pros and cons of the various technologies. Beam coupling: a good general purpose choice Beam Couplings Beam type couplings are manufactured from a single piece of material, usually aluminum, and utilize a system of spiral cuts to accommodate misalignment and transmit torque. Versions of this article have been published in: Single beam couplings are an economical option that are best utilized in lower torque applications, especially in connections to encoders and other light instrumentation. Multiple beam couplings, which usually consist of 2 or 3 overlapping beams, attack the problem of low torsional rigidity. They generally have good performance characteristics and are an economical choice. For many applications, beam couplings are a good place to start. The single piece design allows the coupling to transmit torque with zero backlash and no maintenance required. Two basic variations on this theme exist: a single beam style and a multiple beam style. The single beam style has one long continuous cut that usually consists of multiple complete rotations. This results in a coupling that is very flexible and yields light bearing loads. It is able to accommodate all types of misalignment, but works best with angular misalignment and axial motion. Parallel misalignment capabilities are reduced because the single beam is required to bend in two different directions at the same time, creating larger stresses in the coupling that could cause premature failure. Although the long single beam allows the coupling to bend easily under misalignment conditions, it has the same affect on the rigidity of the coupling under torsional loads. The relatively large amount of windup under torsional loads adversely affects the accuracy of the coupling and reduces its overall performance.

Open the catalog to page 1

www.ruland.com Jaw coupling: best for shock absorption Oldham Couplings The oldham coupling is a three piece coupling comprised of two hubs and a center member. The center disk, which is usually made of a plastic or, less commonly, a metallic material, is the torque transmitting element. Torque transmission is accomplished by mating slots in the center disk, located on opposite sides of the disk and oriented 90 degrees apart, with drive tenons on the hubs. The slots of the disk fit on the tenons of the hub with a slight press fit. This press fit allows the coupling to operate with zero...

Open the catalog to page 2

Disc coupling: torsionally rigid high misalignment capability Disc Couplings Disc couplings are comprised of, at a minimum, two hubs and a thin metallic or composite disc that is the torque transmitting element. The disc is fastened to the hubs usually with a tight fitting pin that does not allow any play or backlash between the disc and hubs. Some manufacturers offer disc couplings with two discs separated by a rigid center member and attached to a hub at each end. The difference between the two variations is quite similar to the difference between the single beam style coupling and the...

Open the catalog to page 3

Bellows Couplings The bellows coupling is an assembly of two hubs and a thin walled metallic bellows. The assembly is created in most cases by either welding the hubs to the bellows or by using an adhesive of some variety. Although other materials can be and are used, the two most common materials for the bellows are stainless steel and nickel. Nickel bellows are manufactured using an electrodeposition method. This method involves machining a solid mandrel in the shape of the finished bellows. The nickel is electrodeposited onto the mandrel and the mandrel is then chemically dissolved,...

Open the catalog to page 4All Ruland Manufacturing Co. catalogs and technical brochures

-

LVO-OF-MCL-IOE-AN

1 Pages

-

LV-0F-MCL-16E-SS

1 Pages

-

LV-0F-MCL-16-A

1 Pages

-

LV-0F-MCL-12-F

1 Pages

-

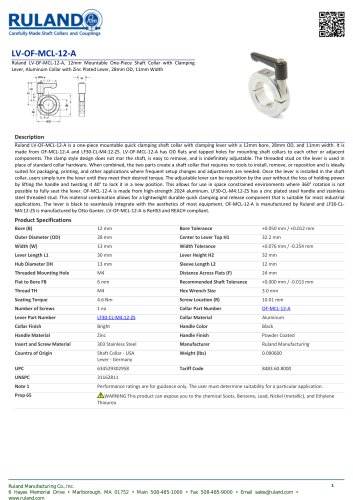

LV-0F-MCL-12-A

1 Pages

-

M-IPL-8-M16X1.5-F

1 Pages

-

M-IPL-4-M8X1-F

1 Pages

-

M-IPL-4.73-3/8X24-F

1 Pages

-

M-IPL-7.9-5/8X18-F

1 Pages

-

MCL-75-F

1 Pages

-

MCL-54-SS

1 Pages

-

MCL-54-F

1 Pages

-

MCL-50-F

1 Pages

-

MCL-24-F

1 Pages

-

MCL-23-SS

1 Pages

-

MCL-23-F

1 Pages

-

ATCL-12-6-F

1 Pages

-

MSCC-20-20-SS

1 Pages

-

MSCC-16-16-F

1 Pages

-

MCLC-15-15-F

1 Pages

Archived catalogs

-

Ruland Shaft Collars & Couplings

16 Pages

-

Ruland Beam Couplings

12 Pages

-

Ruland Oldham Couplings

6 Pages

-

Ruland Jaw Couplings

6 Pages

-

Ruland Bellows Couplings

6 Pages